Assembly type slurry storage device for filling deep underwater confined space and assembly method of assembly type slurry storage device

A technology of confined space and assembly method, which is applied in fillings, safety devices, earthwork drilling, etc., can solve the problems of loss of fluidity, limiting the scope of goaf treatment, reducing stone rate and stone body strength, etc. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

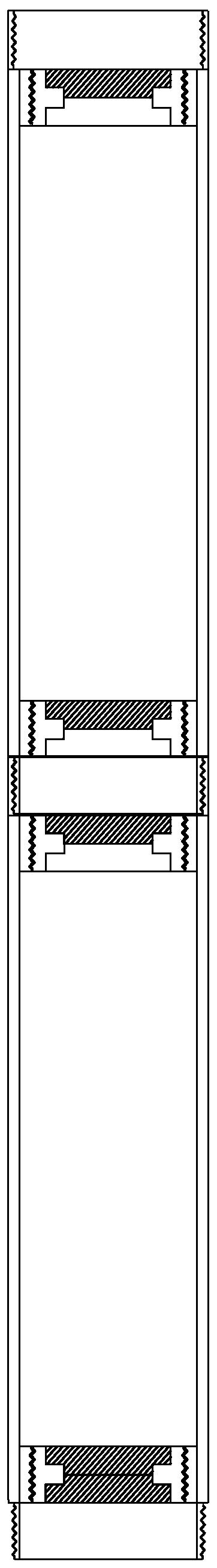

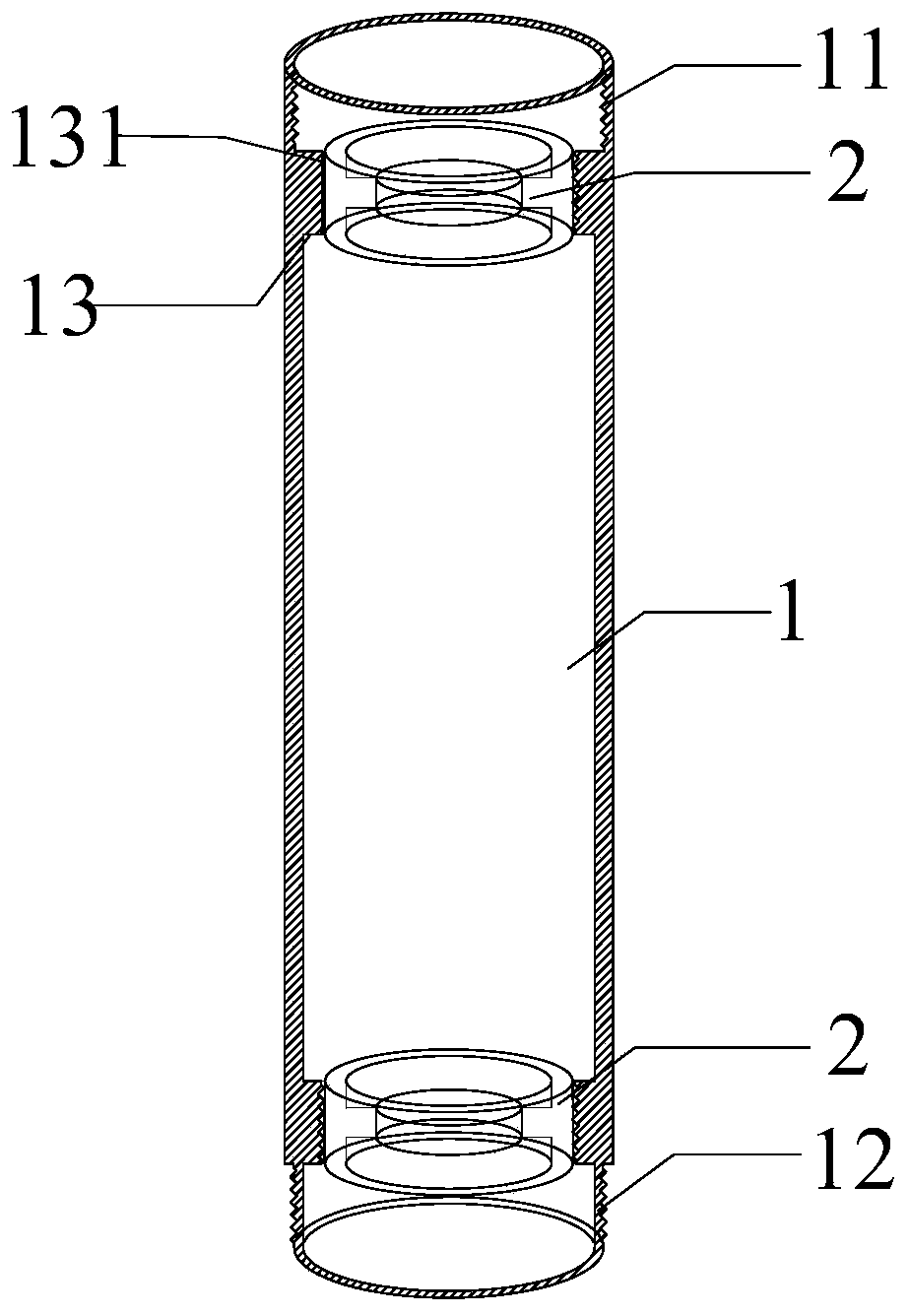

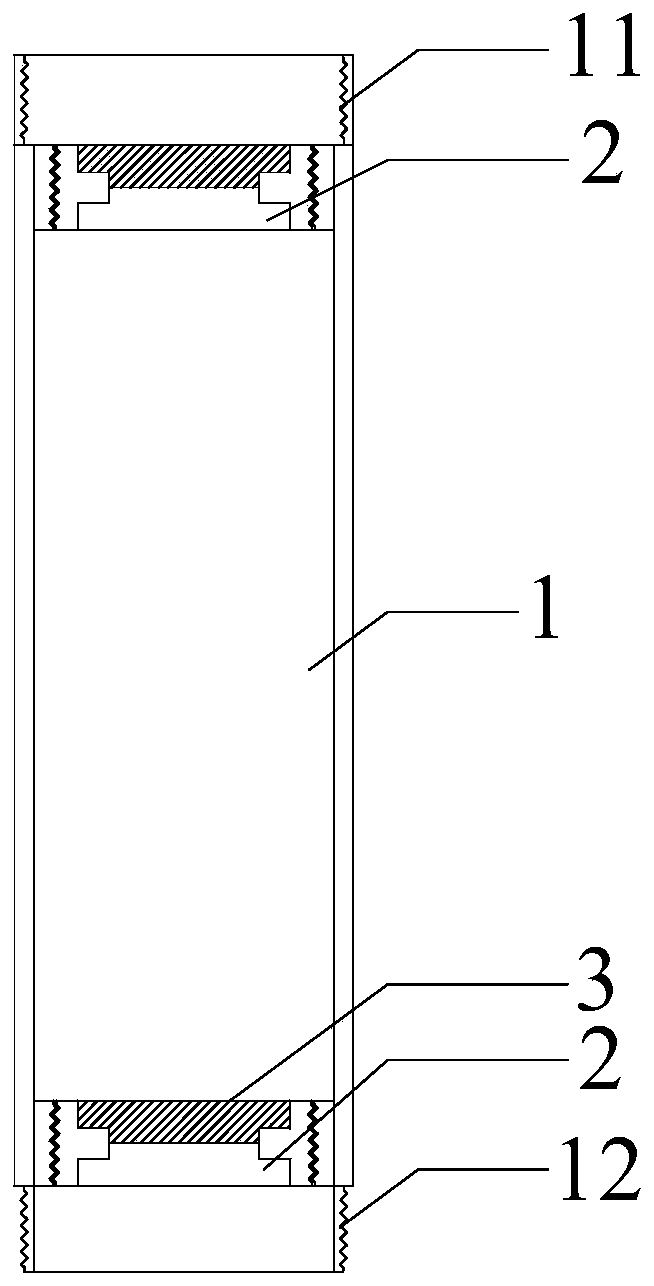

[0065] refer to figure 1 , figure 2 , image 3 As shown, a specific embodiment of the present application provides a prefabricated slurry storage device for filling deep underwater confined spaces, including a plurality of storage storage units connected end to end, and each storage storage unit includes a pipe body 1. Plug 2 and plug 3. Each slurry storage unit is relatively independent and detachable threaded.

[0066] The length of pipe body 1 is about 3 meters, preferably cylindrical, and its interior is hollow, has a cavity with the same axial direction. The body 1 includes a first port and a second port. The inner wall of the first port of the pipe body 1 is provided with an internal thread 11, and an annular boss 13 is provided below the internal thread 11. The surface of the annular boss 13 is also provided with a thread 131 for convenience. The plug 2 is connected with the thread of the pipe body.

[0067] In other technical files, the plug 2 can also be fixed on...

Embodiment 2

[0096] In this embodiment, the plug assembly adopts a one-way valve, through which the slurry can only be poured into the goaf from the outside, and at the same time prevents the groundwater in the goaf from seeping into the pipe.

[0097] The outer side of the one-way valve has an outer threaded surface that is rotatably matched with the plug, and the outer threaded surface can be formed on an annular sleeve, and the sleeve is sleeved and fixed on the outer side of the one-way valve.

[0098] The outer threaded surface of the sleeve body can be rotatably matched with the plug 2, and can also be rotatably matched directly with the inner wall surface of the pipe body.

[0099] The one-way valve can be purchased directly on the market, and its principle and structure will not be described in detail.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com