Method and apparatus for measuring tire performance

一种测量方法、轮胎的技术,应用在轮胎测量、测量装置、轮胎零部件等方向,能够解决出现误差、低再现性等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

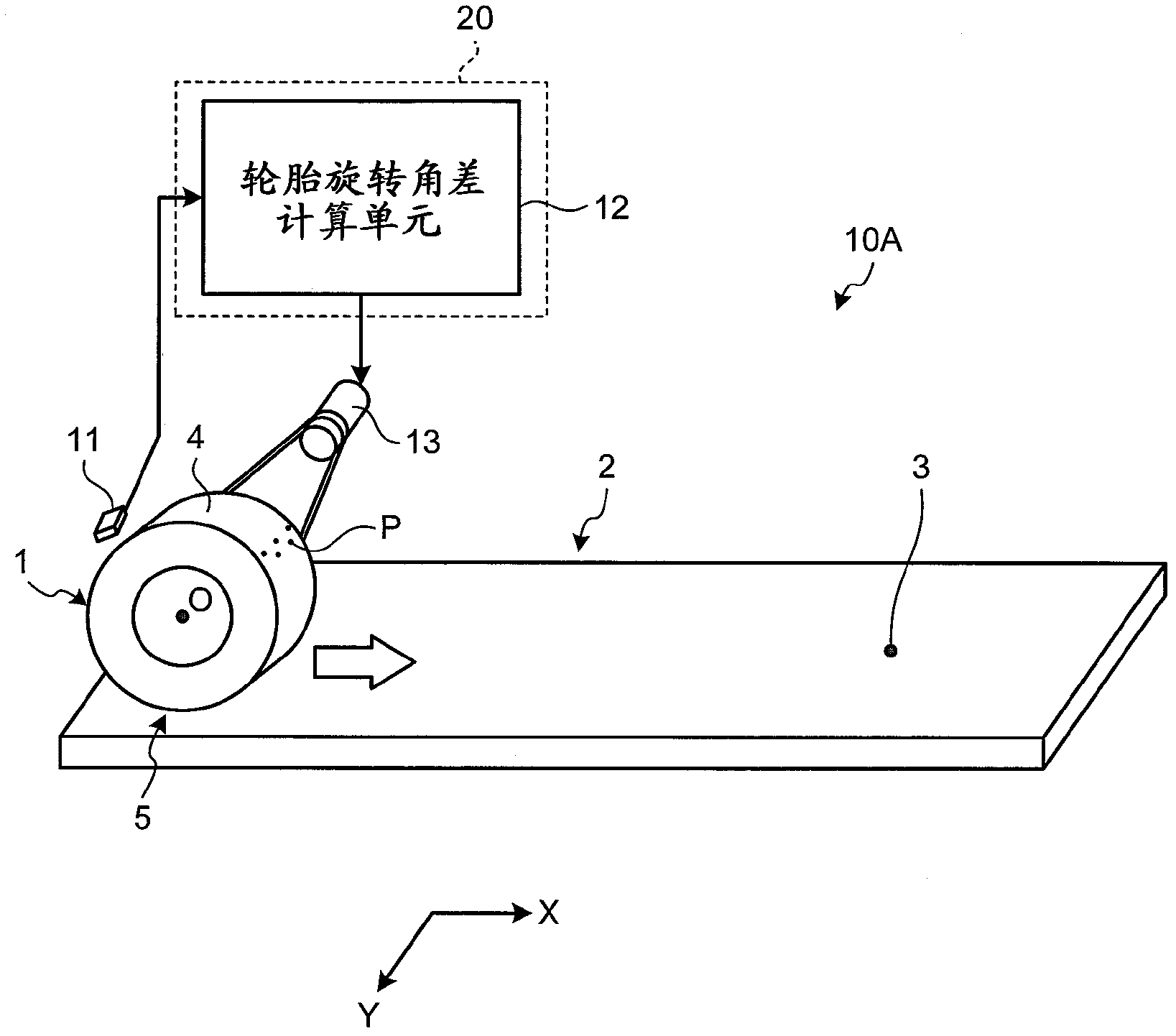

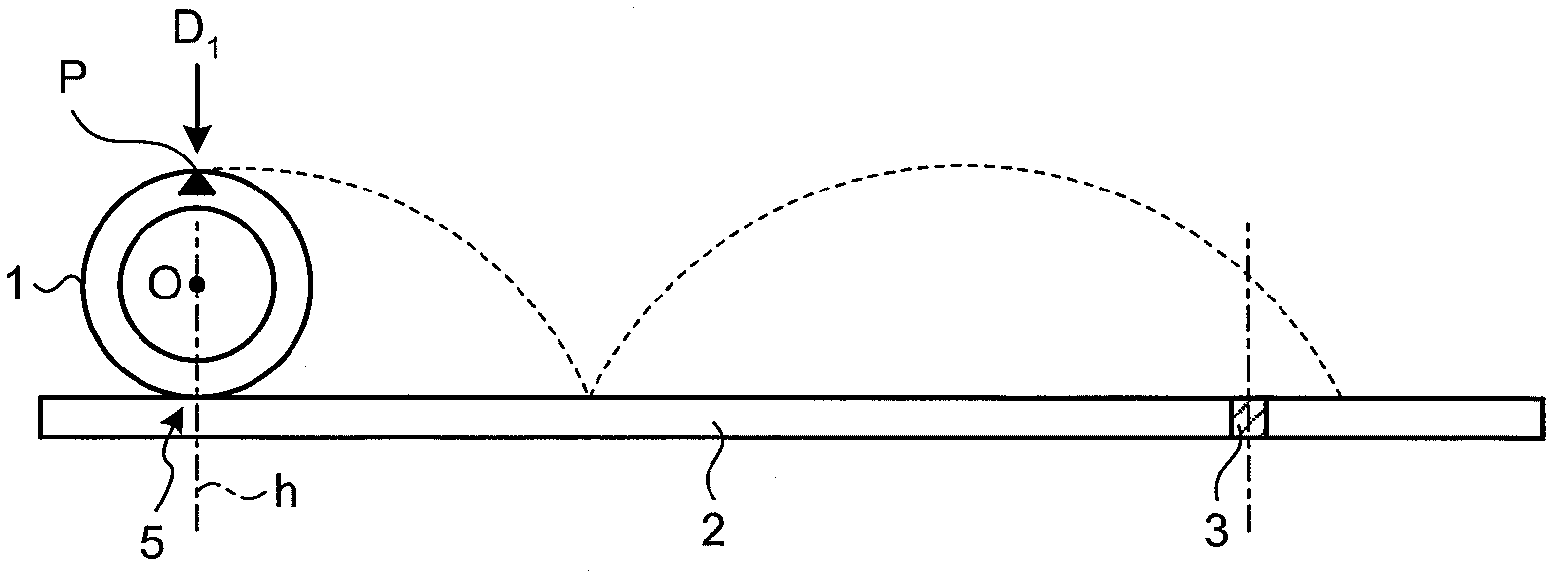

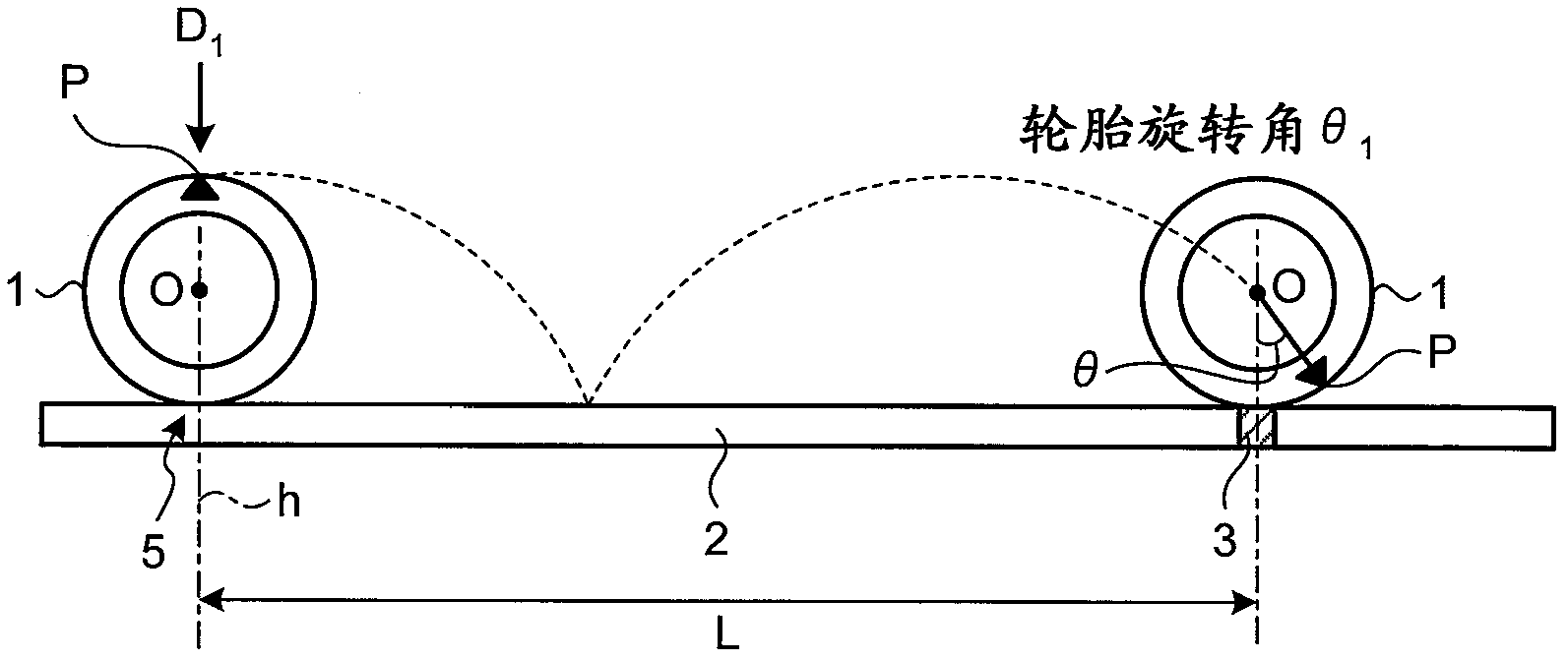

[0018] Exemplary embodiments of the tire performance measuring method and the tire performance measuring apparatus according to the present invention will be described in detail below with reference to the accompanying drawings. The following description does not limit the invention. The constituent elements of the embodiments described below include elements replaceable or easily conceivable by those skilled in the art, or elements substantially equivalent to these elements. Although the tire performance measuring method and the tire performance measuring apparatus according to the present invention can be applied to measuring ground contact pressure, shear stress, and slippage amount of tires, measurement of ground contact pressure will be described below as an example.

[0019] figure 1 is a schematic diagram of a tire performance measuring device 10A employing a tire performance measuring method according to an embodiment of the present invention. figure 1 The tire perfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com