Device for testing horizontal rigidity performance of motorcycle frame

A test device and motorcycle technology, applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problems of unfavorable new products, waste of labor, and difficulty in consistent working conditions, and achieve the solution of strength and stiffness performance test evaluation Demand, simple and reasonable structure, and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

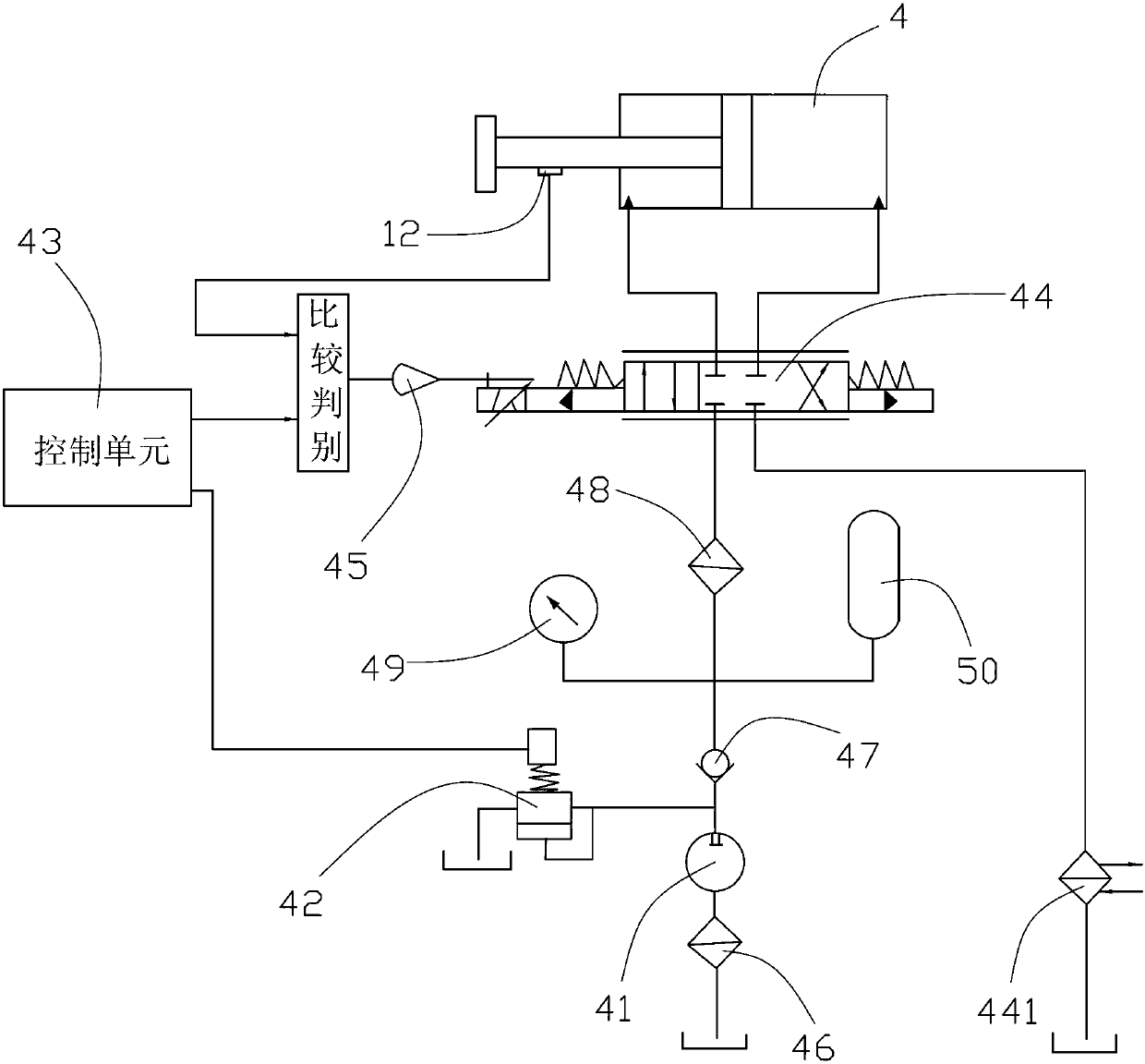

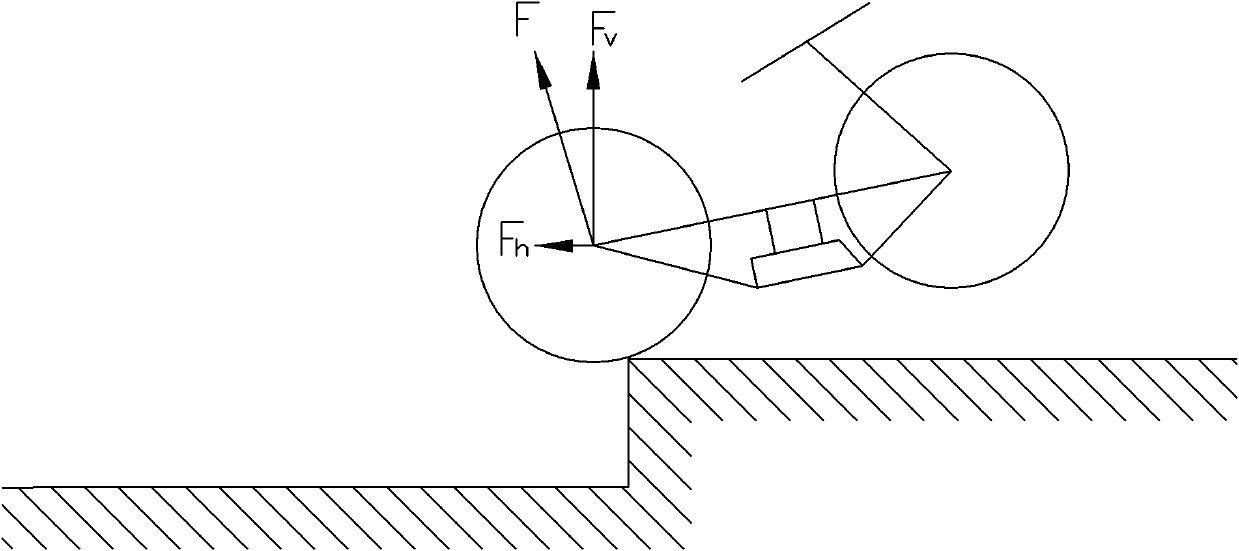

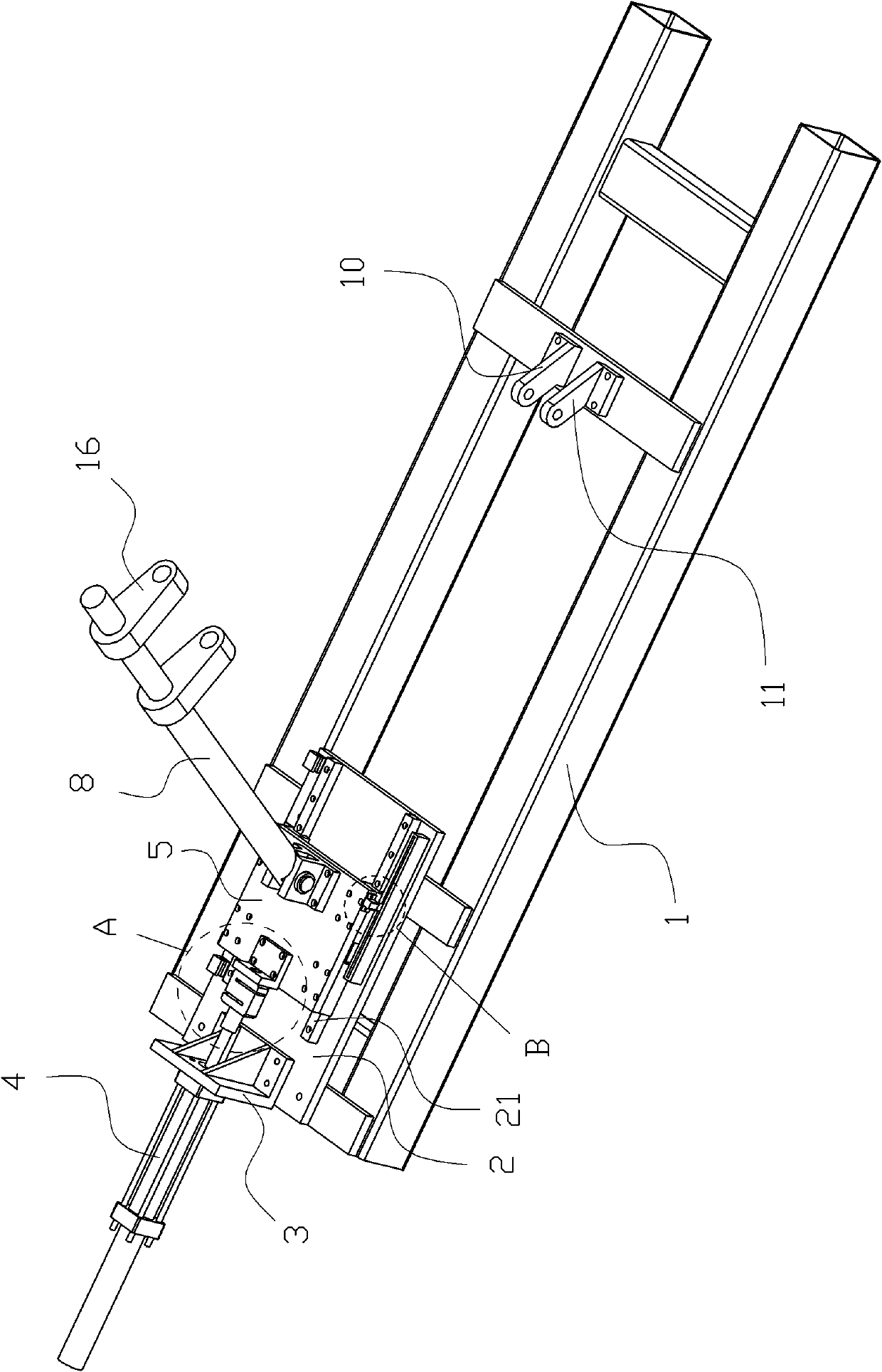

[0025] refer to Figure 2~Figure 11 , a kind of motorcycle frame horizontal rigidity performance test device of the present invention, it comprises base 1, and one end of base 1 is equipped with horizontal bearing 2, and pressure cylinder 4 is installed on horizontal bearing 2 through oil cylinder bearing 3, and pressure cylinder 4 is used to produce the road simulation horizontal pulling force to motorcycle frame 18, and the piston rod end of pressure cylinder 4 is connected with horizontal sliding seat 5, preferably, pressure cylinder 4 is connected with horizontal sliding seat 5 through pressure sensor 12, and pressure sensor 12 One end is connected to the end of the piston rod of the pressure cylinder 4, and the other end is fixedly connected to the horizontal sliding seat 5 through the sensor fixing seat 13, and the horizontal sliding seat 5 is installed on the slide rail 21 on the horizontal support 2 through a slider. The upper surface of horizontal slide seat 5 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com