Method for inspecting acceptability of amorphous alloy products by means of sound

An amorphous alloy and sound detection technology, which is applied in the processing of detection response signals and the use of sound waves/ultrasonic waves/infrasonic waves to analyze solids, etc., can solve the problems of unfavorable mass detection and long detection cycle, and achieve short detection process and reduce errors. Judgment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

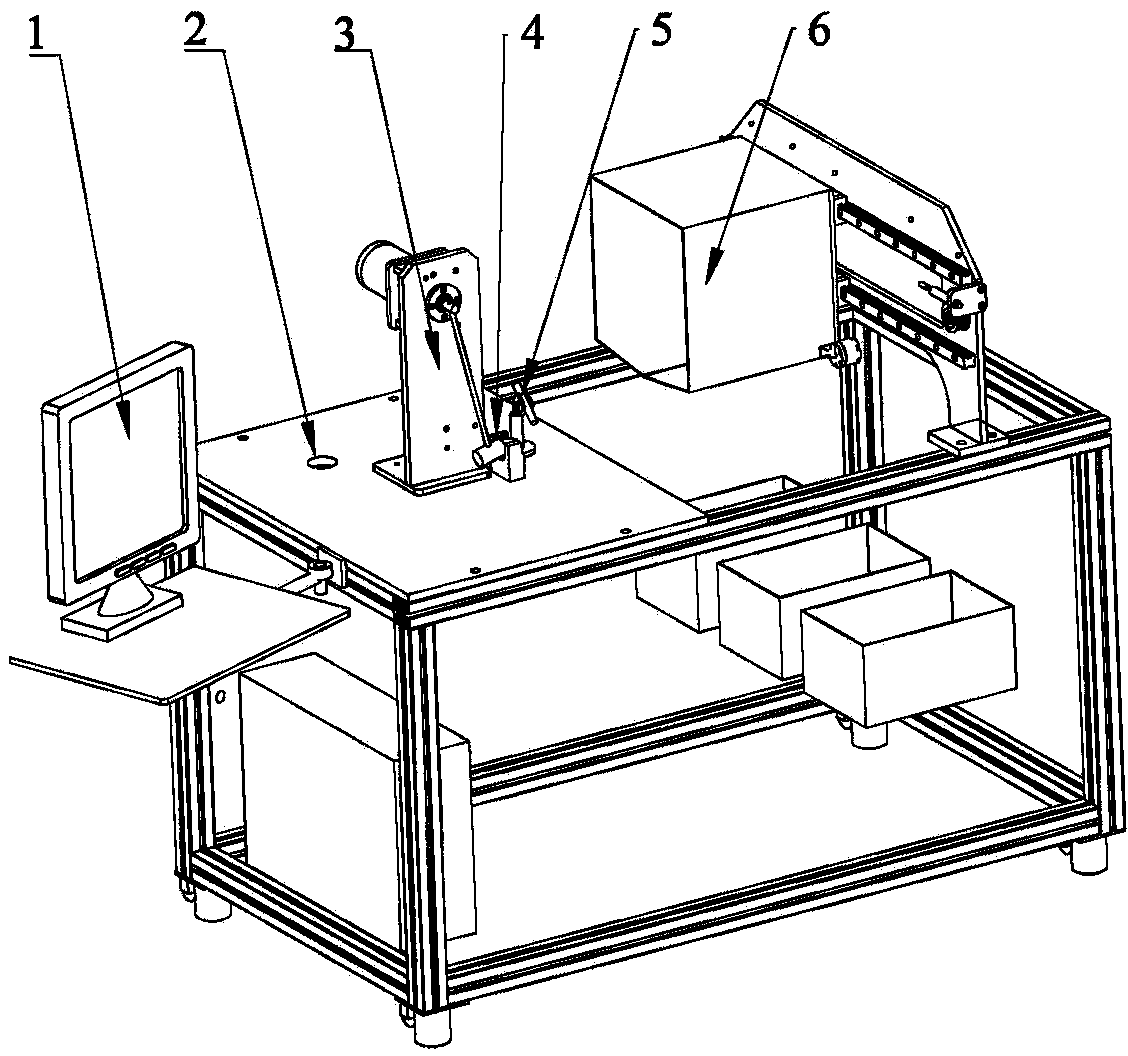

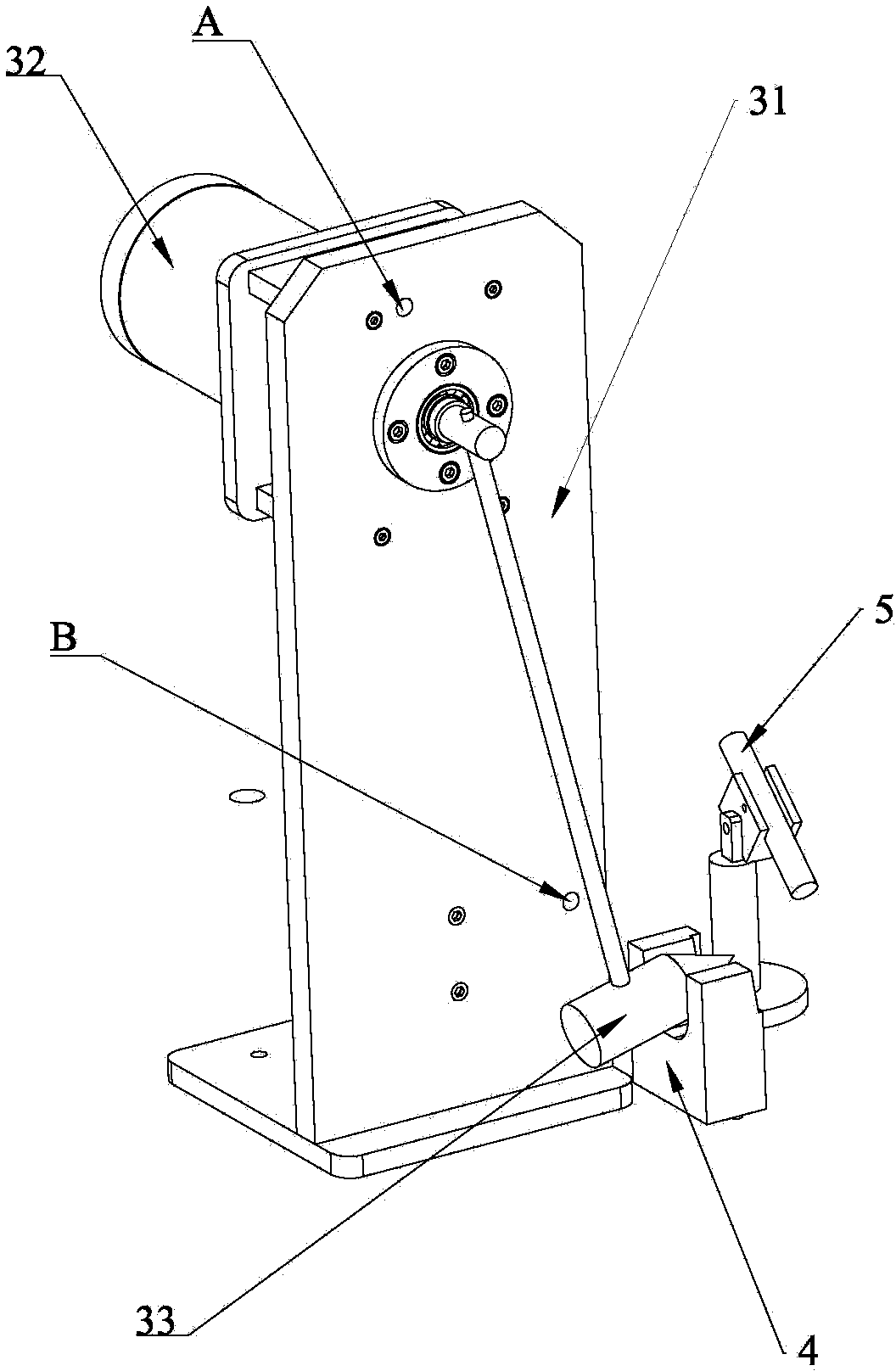

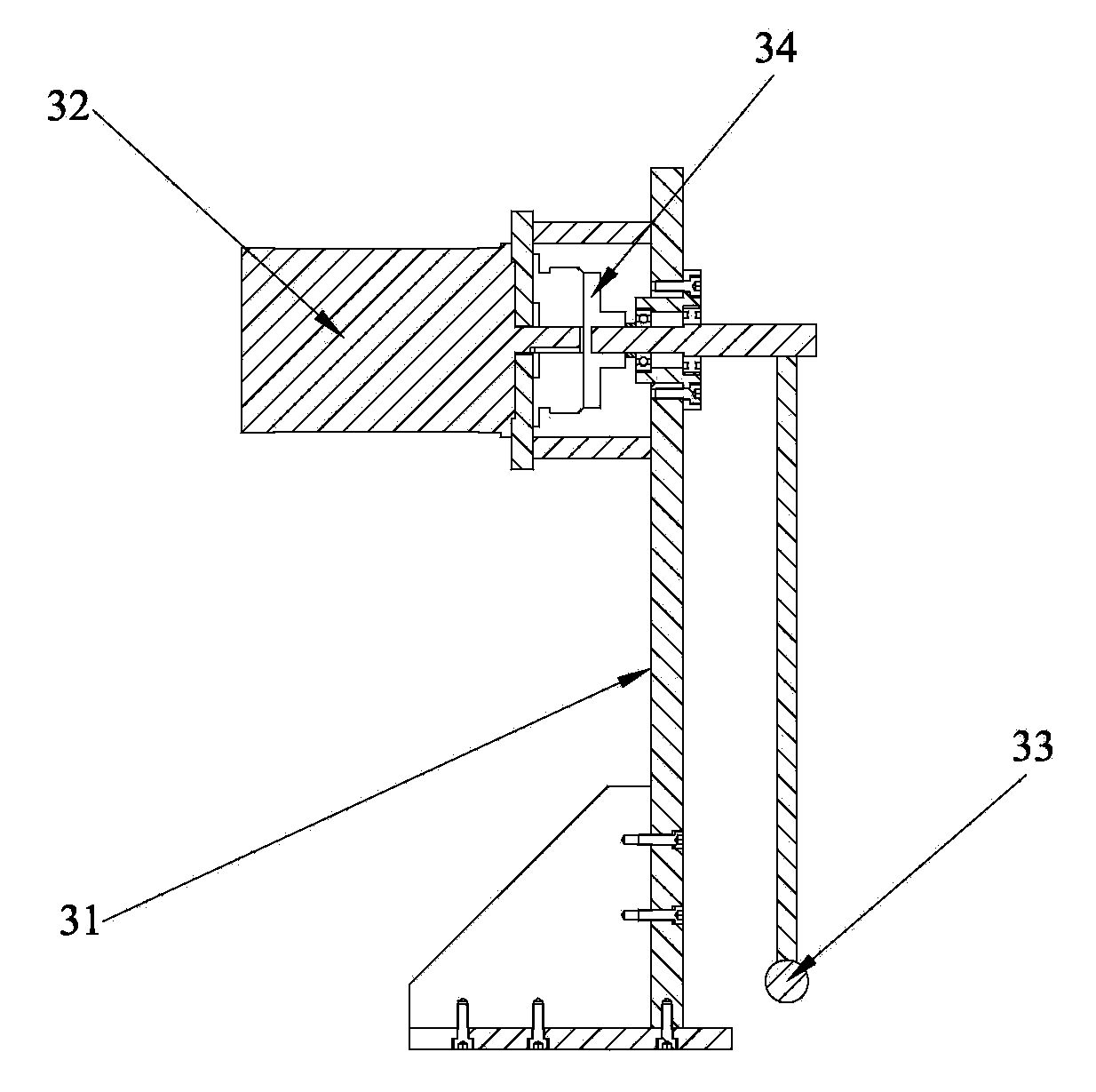

[0015] In order to make the technical problems, technical solutions and beneficial effects solved by the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0016] The inventors of the present invention have found that the amorphous alloy material has better energy conduction performance when receiving external energy, and qualified products can conduct the received energy well into the entire product in the form of vibration. Due to the long time of its own vibration, the attenuation time of the collected sound signal is also long; the conduction of vibration energy of unqualified products will stop when it encounters internal defects such as holes and cracks, and the detected sound The attenuation time of the signal is sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com