Withstand voltage test terminal structure of cross-linked cable under 110kV voltage class or below

A cross-linked cable and withstand voltage test technology, which is applied in the direction of testing dielectric strength, can solve problems such as high price, poor control, and complex structure, and achieve the effects of convenient operation, improved production efficiency, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

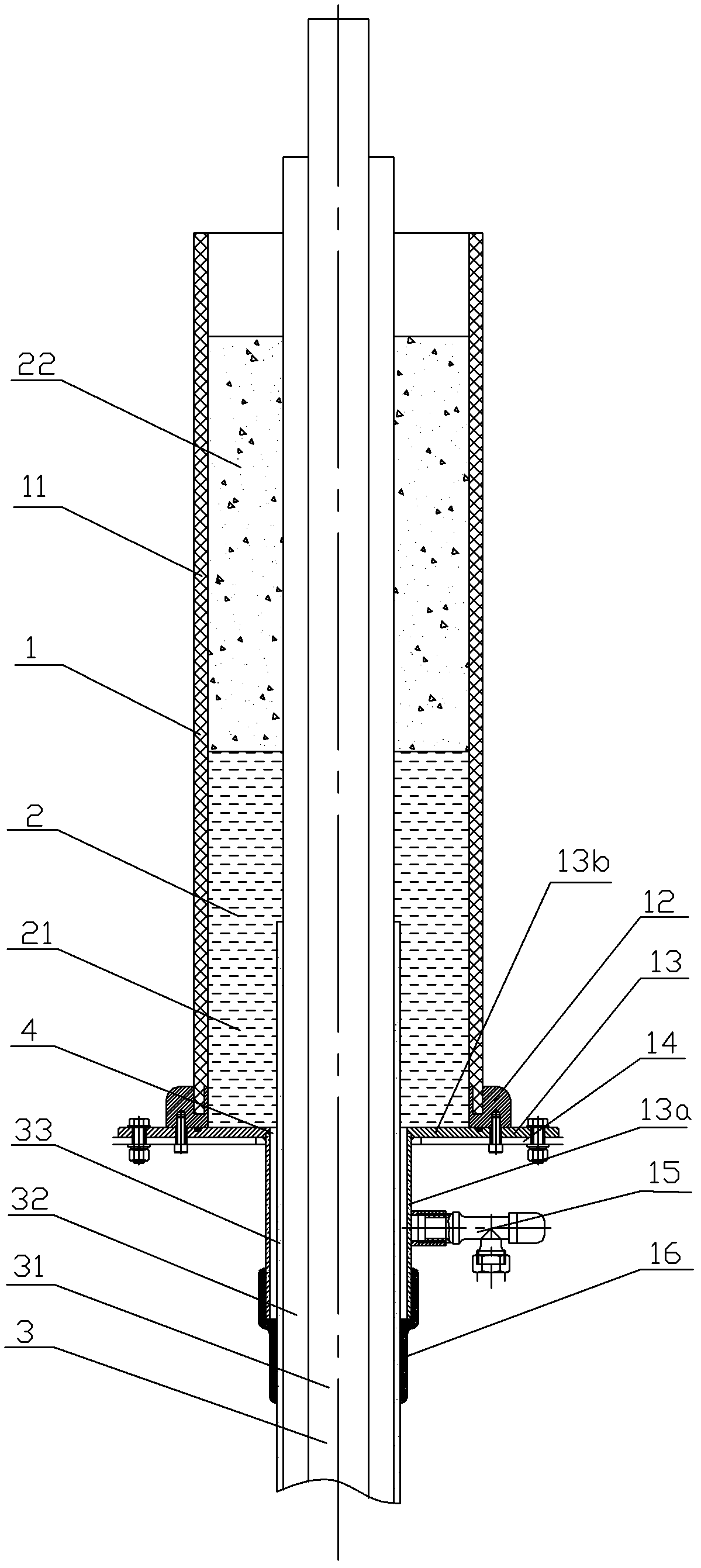

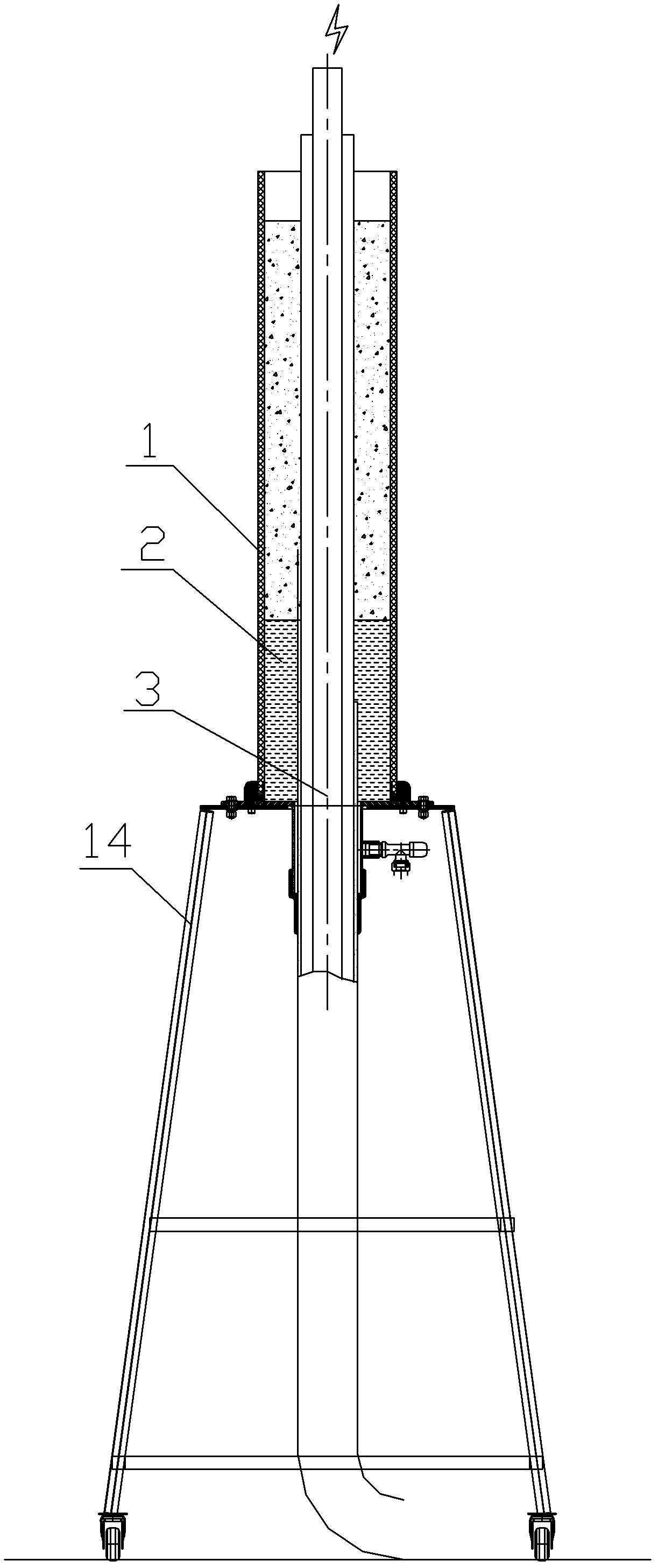

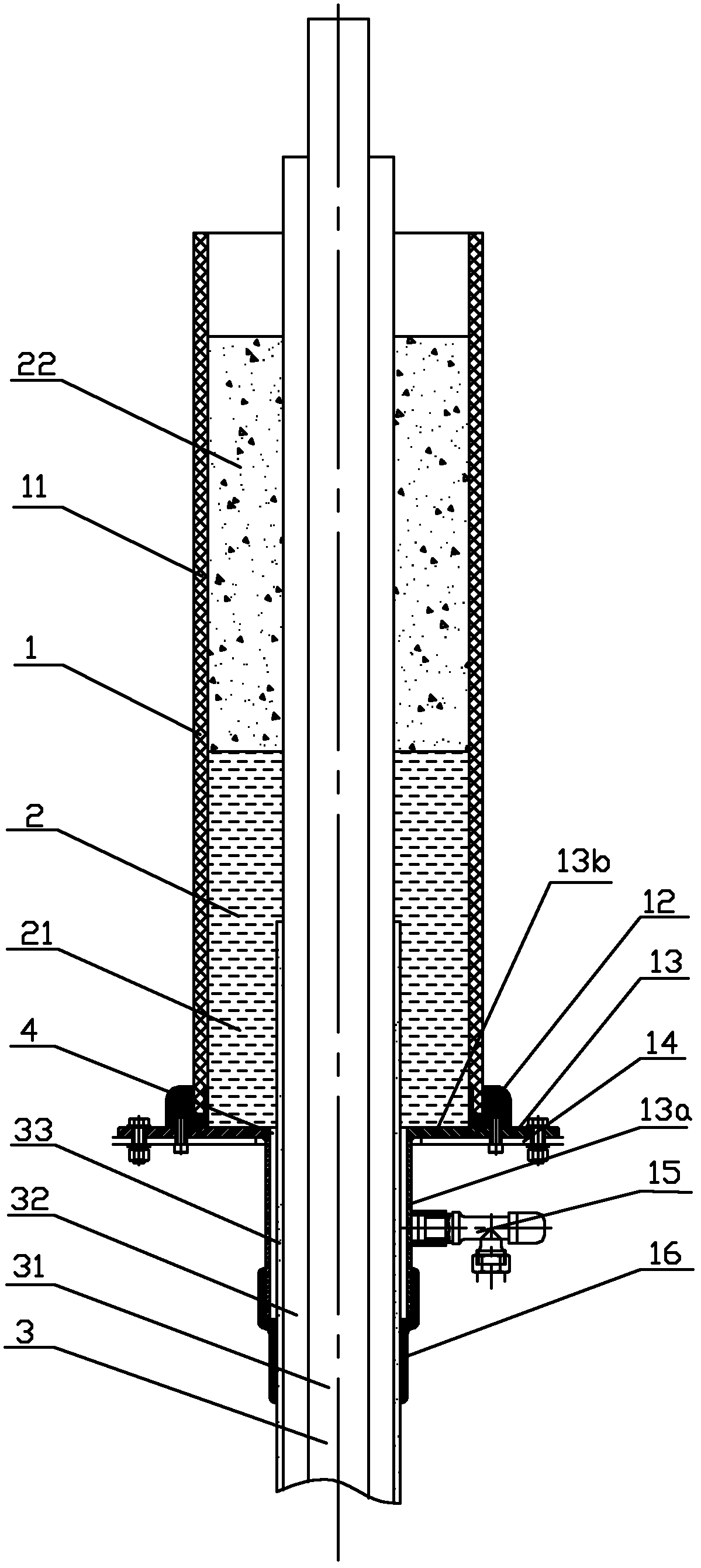

[0016] A specific embodiment of the present invention is as follows: the oil cup 1 is placed upright, first peel off a part of the cable insulation shielding layer 33 at one end of the test cable 3, and penetrate through the bottom round hole 4 of the test terminal to make the cable core 31 1. The upper end of the cable insulation layer 32 extends out of the oil cup 1, the upper end of the cable insulation shielding layer 33 is located in the oil cup 1, and is heated and sealed with the heat-shrinkable tube 16 that has been inserted into the test cable 3 in advance, and then the put Oil port 15 valve is closed tightly, pours into the liquid 2 that is the mixture of insulating oil and tap water, due to the reason of density, this mixture is divided into upper and lower two layers, and the upper layer is insulating oil 22, and the lower layer is tap water 21. Among them, the upper surface of the tap water 21 needs to be higher than the highest point of the cable insulation shield...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com