Magnetostrictive linear driver with linear output

A magnetostrictive, linear drive technology, applied in piezoelectric/electrostrictive or magnetostrictive motors, generators/motors, electrical components, etc., can solve problems such as difficult precision control, and achieve good linear output , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

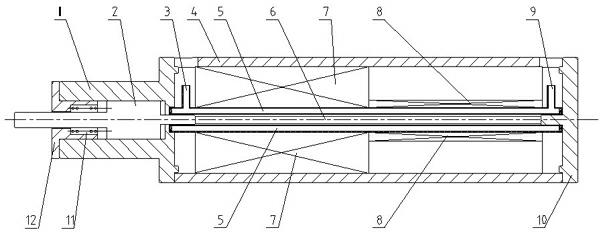

[0014] Example 1 as attached Figure 1-3 Shown: A linear output magnetostrictive linear actuator, including one end of the cylindrical shell 4 fixedly connected to the guide sleeve 1, the other end of the cylindrical shell 4 fixedly connected to the closed end cap 10, a hollow water cooling sleeve 5 The closed two ends are respectively installed in the center of the guide sleeve 1 and the end cover 10, the two ends of the hollow water cooling sleeve 5 are respectively provided with a water inlet pipe 3 and a water outlet pipe 9, and the magnetostrictive rod 6 is mounted on the hollow water cooling sleeve 5 with clearance fit. Center; the coil connected with the current source is installed in the annular space between the inner wall of the cylindrical shell 4 and the hollow water-cooling sleeve 5, and one end of the output shaft 2 that is slidingly fitted with the inner cavity of the guide sleeve 1 penetrates into the hollow water-cooling sleeve 5 center, and close to the end...

Embodiment 2

[0016] Example 2 : Embodiment 1 In the magnetostrictive linear actuator with linear output, the number of radially wound layers of 1# coil 7 is 60 layers, and the number of radially wound layers of 2# coil 8 is 12 layers.

Embodiment 3

[0017] Example 3 : Embodiment 1 In the magnetostrictive linear actuator with linear output, the number of radially wound layers of 1# coil 7 is 70 layers, and the number of radially wound layers of 2# coil 8 is 18 layers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com