Piezoelectric cable with piezoelectric effect, preparation method and use thereof

A piezoelectric cable, piezoelectric effect technology, applied in the manufacture/assembly of piezoelectric/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, circuits, etc. Short, high cost problems, to achieve the effect of good voltage response sensitivity, low impedance per unit length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

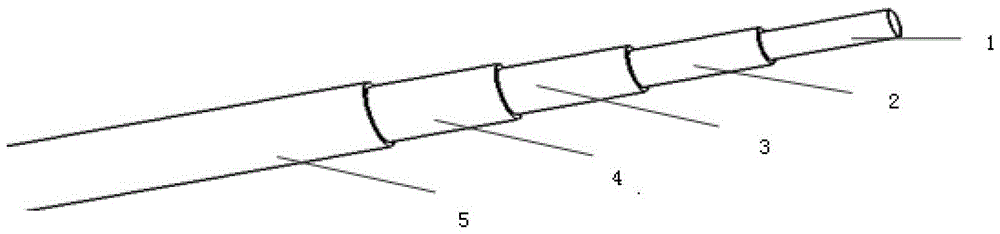

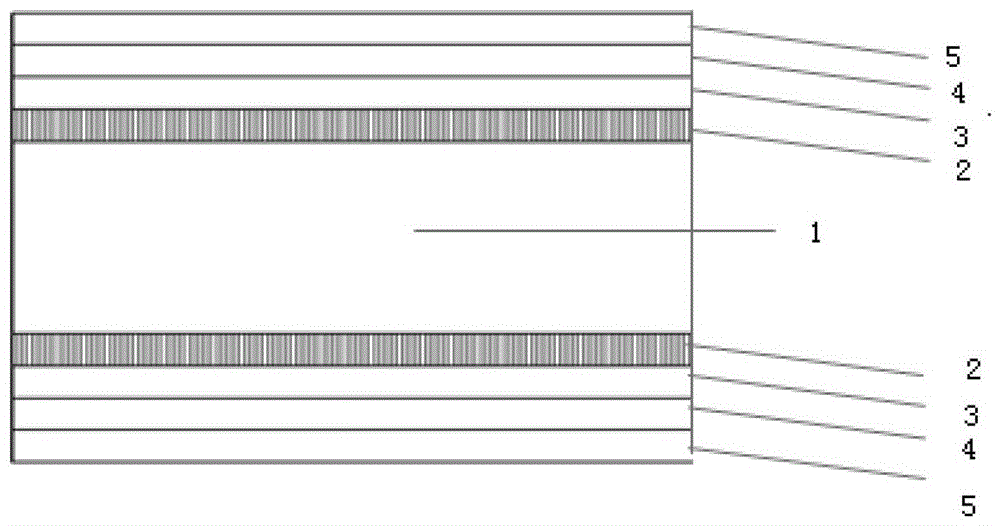

[0074] Embodiment 1 is applicable to the preparation of the cable that is used as traffic shaft sensor

[0075] Industrial aluminum with a purity of 99.5% and a diameter of 1.5 mm is selected as the first electrode core 1 . The first electrode core 1 was polished with 8000-mesh sandpaper until the surface roughness Rz was 12 microns, and then conventional ultrasonic cleaning was performed for 15 minutes. Chromium was radio-frequency sputtered on the surface of the first electrode core 1 by a conventional method to form a chromium layer with a thickness of 10 nm, and then zinc oxide was deposited on the chromium layer by a conventional method to form a zinc oxide seed layer with a thickness of 50 nm.

[0076] Prepare 0.1mol / L concentration of equimolar hexamethylenetetramine (HMTA) and zinc nitrate hexahydrate (ZnNO 3 6(H 2 (0))), the culture solution was placed under the vertically placed first electrode core 1, and grown in a mechanical convection heating furnace (model: Ya...

Embodiment 2-3

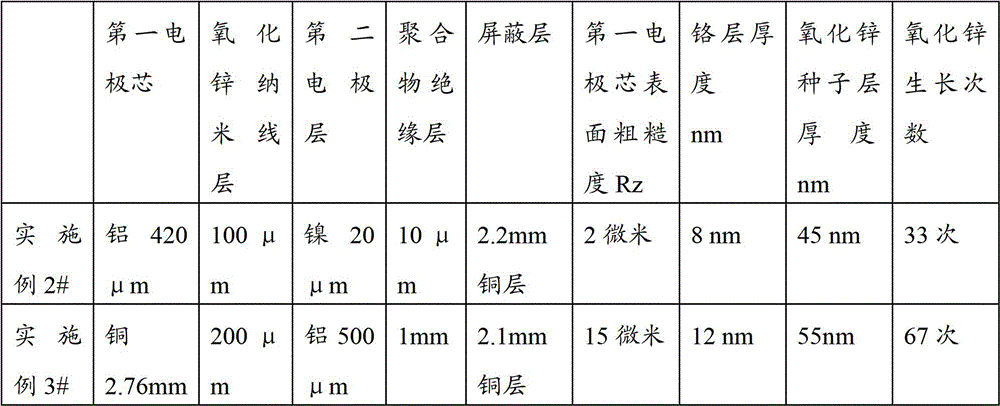

[0078] Embodiment 2-3 is applicable to the preparation of the cable that is used as traffic axis sensor

[0079]The preparation methods used in Examples 2-3 are basically the same as those in Example 1, except for Table 1.

[0080] Table 1

[0081]

Embodiment 4-6

[0082] Embodiment 4-6 is applicable to the preparation of the cable that is used as piezoelectric cable switch

[0083] The preparation methods used in Examples 4-6 are basically the same as those in Example 1, except for Table 2.

[0084] Table 2

[0085]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com