Second-order ladder groove bottom graphical printed board and processing method thereof

A processing method and stepped groove technology are applied in multi-layer circuit manufacturing and printed circuit components, etc., which can solve problems such as easy peeling off of tape, inability to produce two-step ladder printed boards, and inability to install plug-in devices, etc., to expand the scope of use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in combination with specific embodiments.

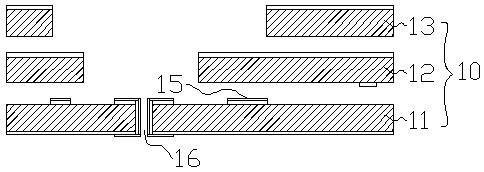

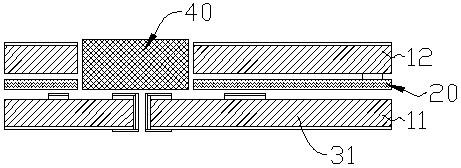

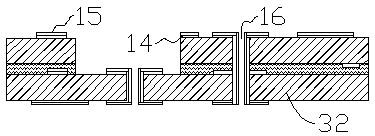

[0033] Such as Figure 1 to Figure 5 It is an embodiment of the processing method of the patterned printed board at the bottom of the two-step stepped groove of the present invention, which includes the following steps:

[0034] (1) Prepare the substrate for making the required sub-board set 10, that is, the first sub-board 11 with the plug-in hole 16 reserved, the second sub-board 12 with the circuit pattern 14, and the third sub-board with the circuit pattern 14 13;

[0035] (2) Pre-processing the first sub-board 11 with the plug-in hole 16 reserved, the second sub-board 12 with the circuit pattern 14, and the third sub-board 13 with the circuit pattern 14;

[0036] Among them, the preprocessing of the first sub-board 11, the second sub-board 12, and the third sub-board 13 with plug-in holes 16 reserved includes the following steps: sequentially perform internal light i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com