Wet gas scrubber

A gas scrubber, wet process technology, applied in separation methods, use of liquid separation agents, chemical instruments and methods, etc., can solve problems such as not too large gas flow range, and achieve the effect of reliable control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

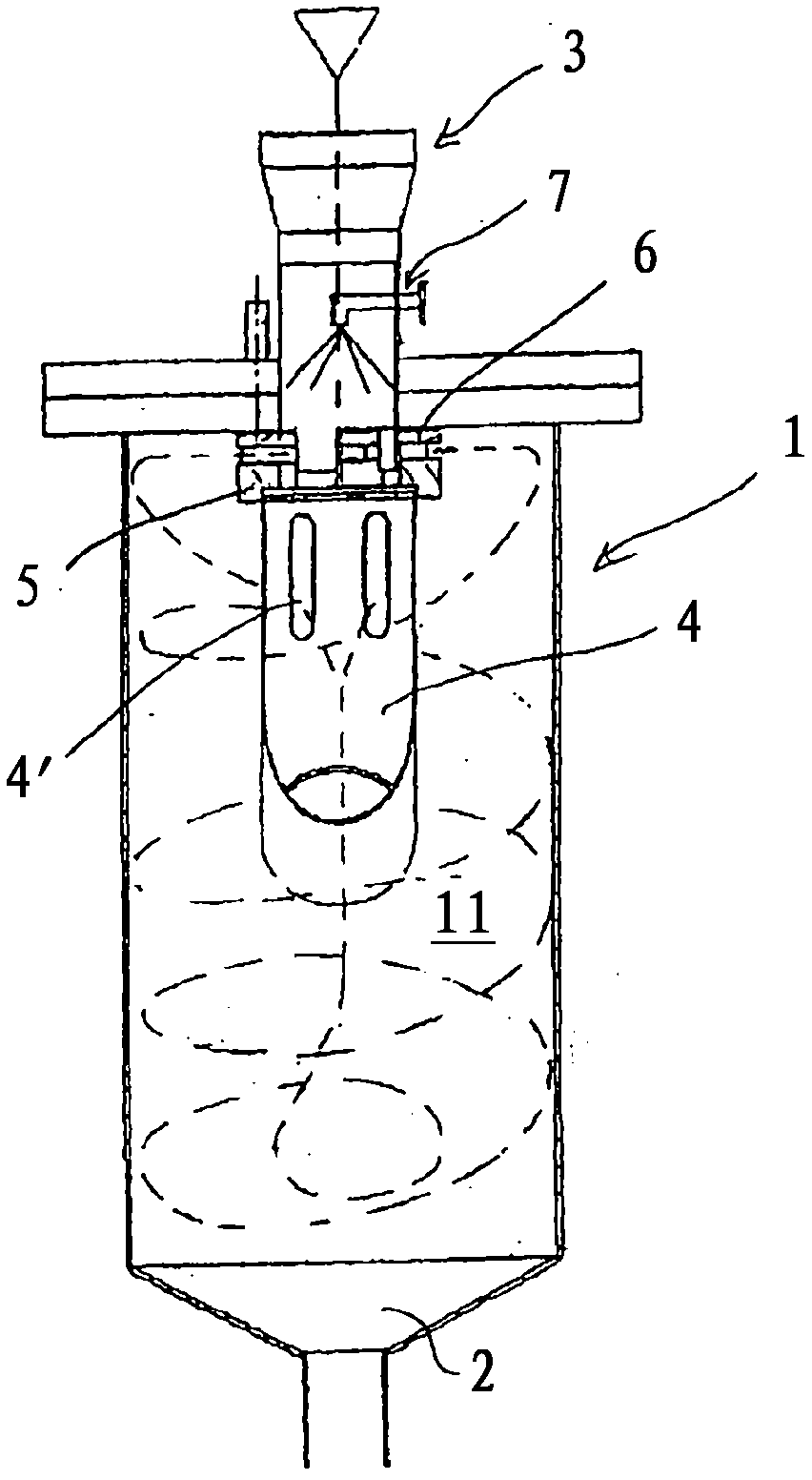

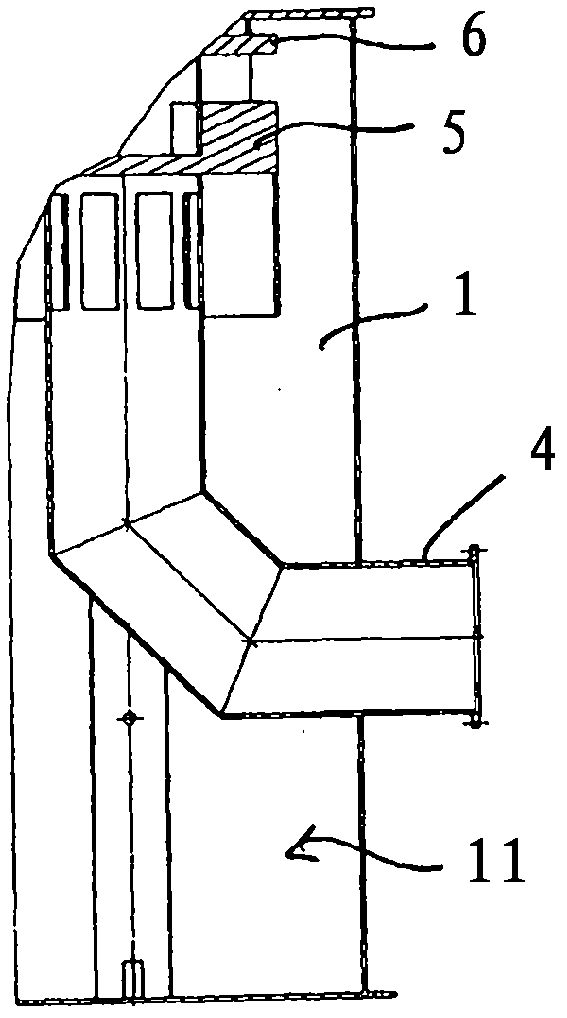

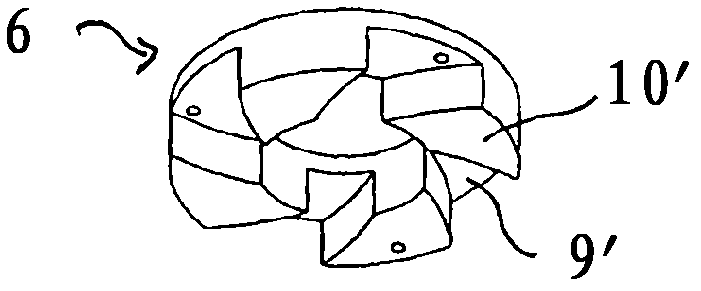

[0020] The wet gas scrubber shown in the accompanying drawings is used to remove solid and / or liquid particulates from water-saturated gases at a consistently high cleaning efficiency. The adjustable Venturi effect cleaning area is formed by two horizontally arranged Venturi effect plates 5, 6, the relative distance between which the two Venturi effect plates are adjustable; this adjustable Venturi effect cleaning area ensures uniform A cleaning efficiency of , wherein a uniform gas velocity and thus a uniform pressure drop is obtained in the case of fluctuating gas volumes.

[0021] The adjustable Venturi effect area comprises a plurality of curved Venturi effect channels 9, 9' extending from the Radially inwardly extending radially outwardly.

[0022] The gas to be cleaned is introduced into the wet gas scrubber from above; the cleaning liquid is injected into the gas to be cleaned through the nozzle 7 before the gas to be cleaned reaches the Venturi effect area. The mixtu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com