Multilayer thermoplastic laminated film arrangement and device and method for laminating

A film structure and lamination film technology, applied in lamination devices, chemical instruments and methods, lamination, etc., can solve the problems of large loss of thermoplastics, etc., and achieve low energy consumption, short lamination cycle, and low equipment cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

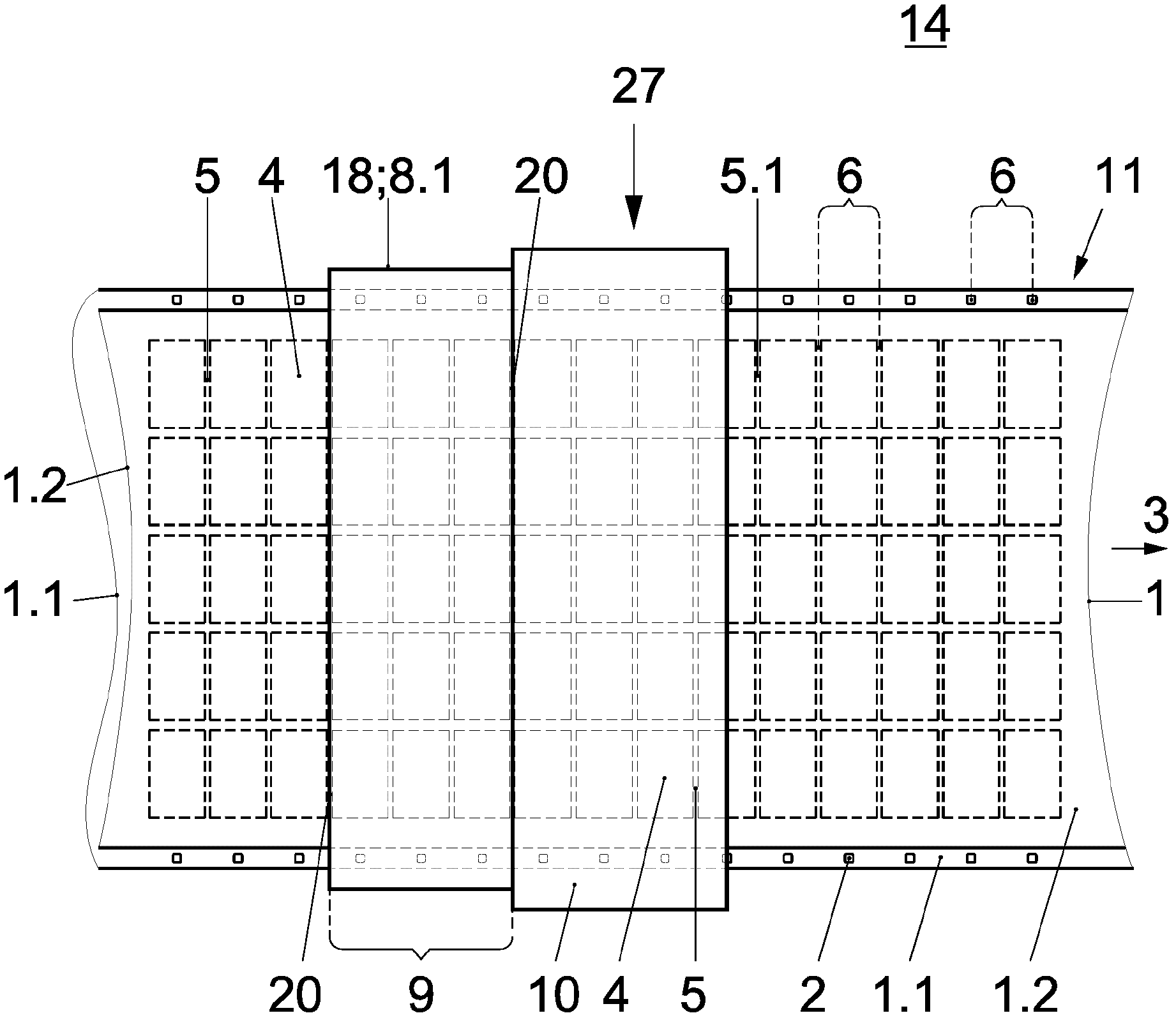

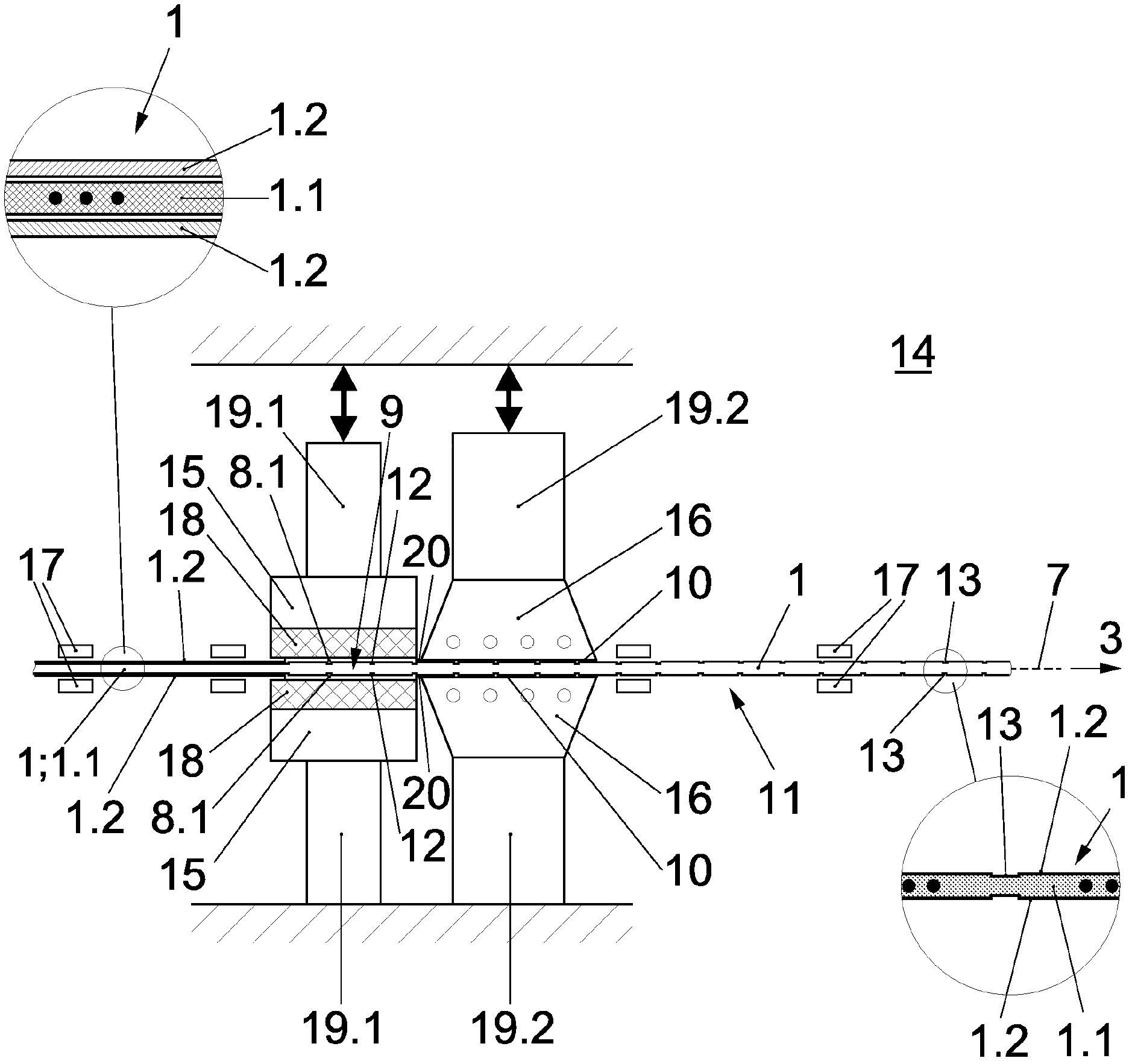

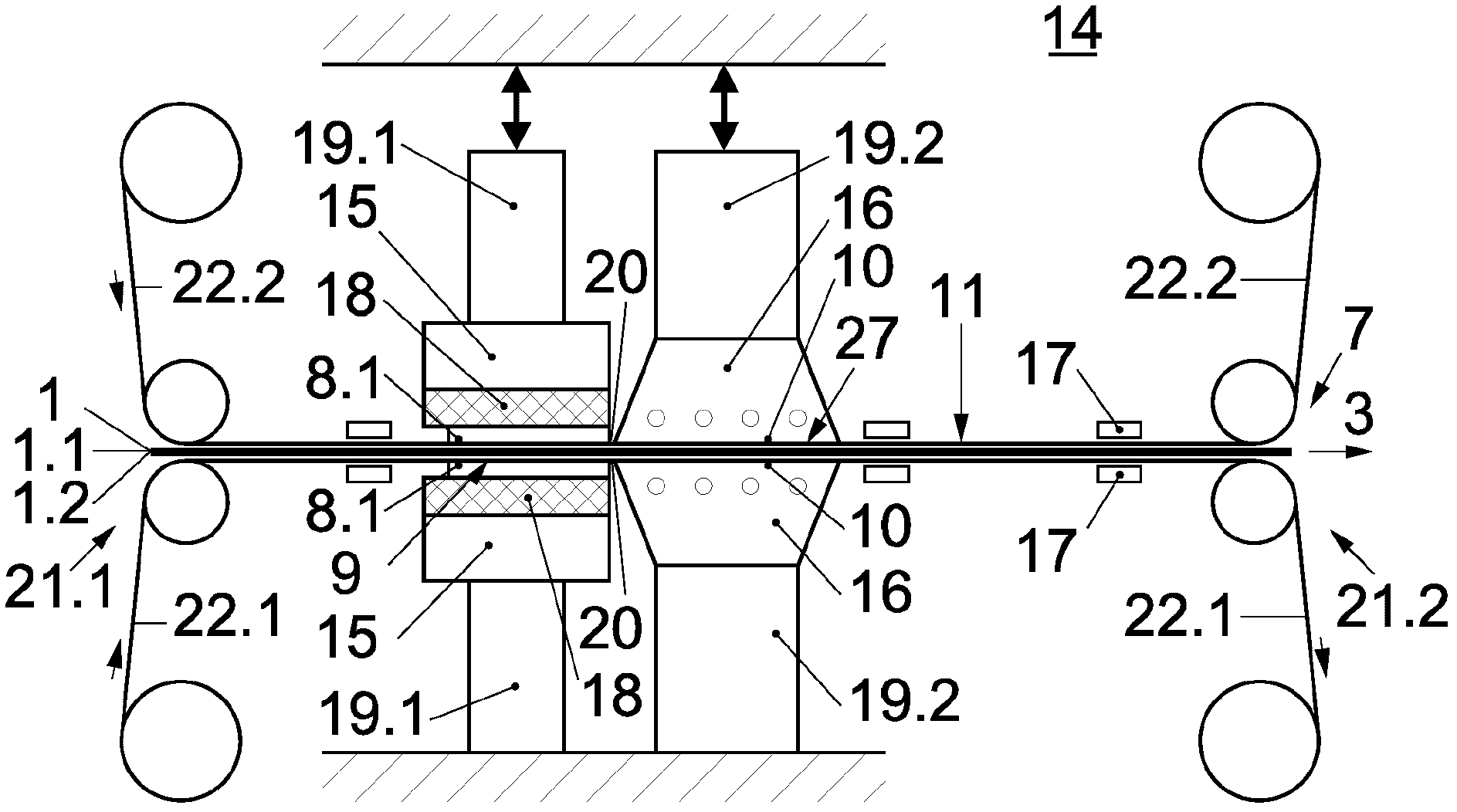

[0071] figure 1 A multilayer thermoplastic film structure 1 in the form of a film strip is shown, which is formed from a thermoplastic film strip or from a plurality of sheet-like film structures arranged in the form of a film strip. The shown film structure 1 is composed, for example, of a 0.20 mm thick base film 1.1 of polycarbonate (PC) and of a cover film 1.2 of polycarbonate each having a thickness of 0.05 mm, arranged on both sides, Wherein, in an example, the cover film 1.2 has a width of 500 mm, and the base film 1.1 has a width of 550 mm, so that the index hole 2 mounted on the edge of the base film 1.1 is not covered by the cover film 1.2.

[0072] In the base film 1.1, the circuit is introduced into a grid of the same shape to produce a chip card or any other card-like product. In the example, five rows of card-sized, 85 mm long surface portions 4 are arranged transversely to the feed direction 3 at intervals of 10 mm. The surface portions 4 have a width of 55 mm ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com