Apparatus, and related method, for the recovering and the pneumatic transportation of dust coming from a filtration system

A filter system and pneumatic conveying technology, which is applied in the field of dust equipment, can solve the problem of overall performance degradation of the filter system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

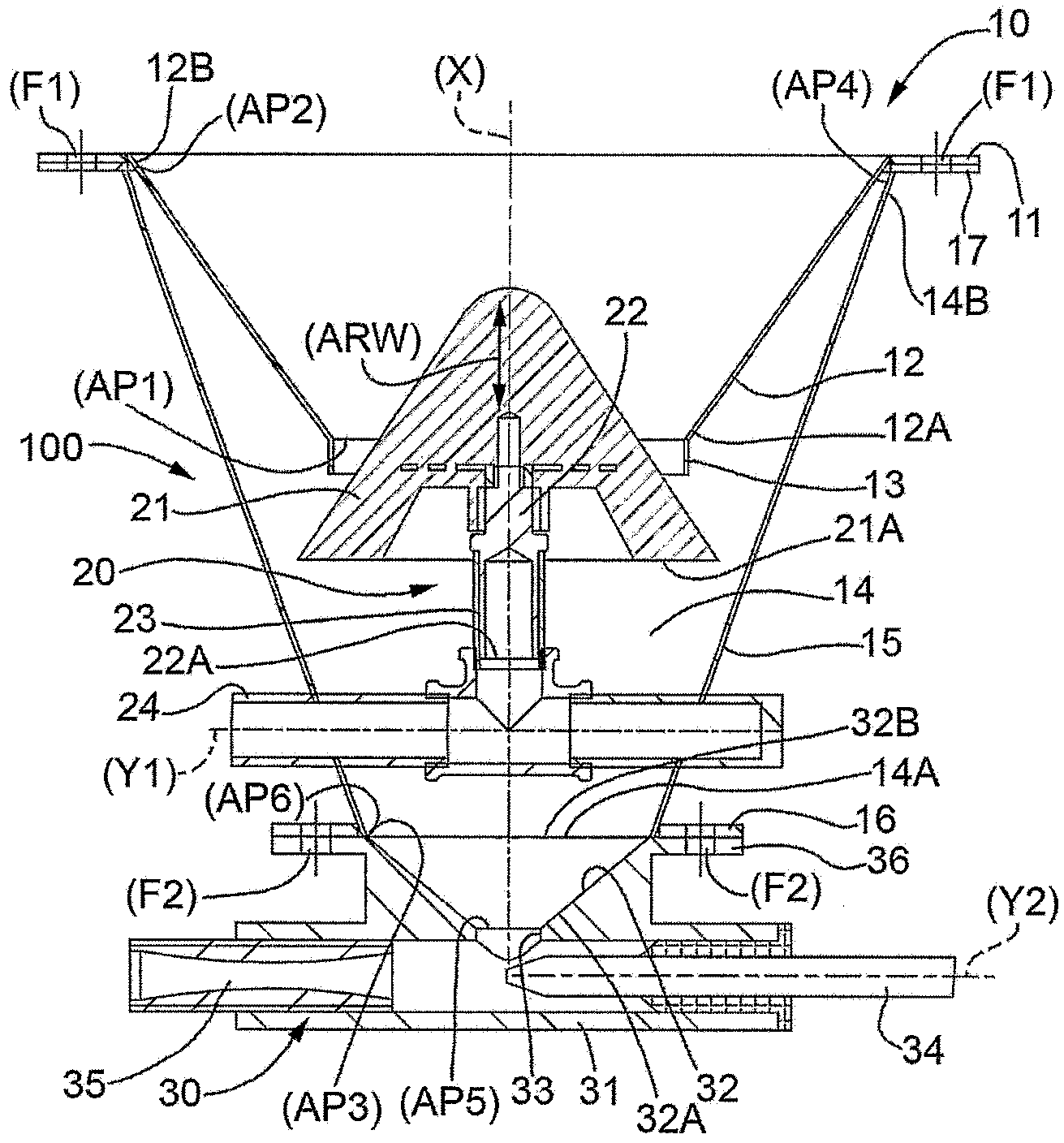

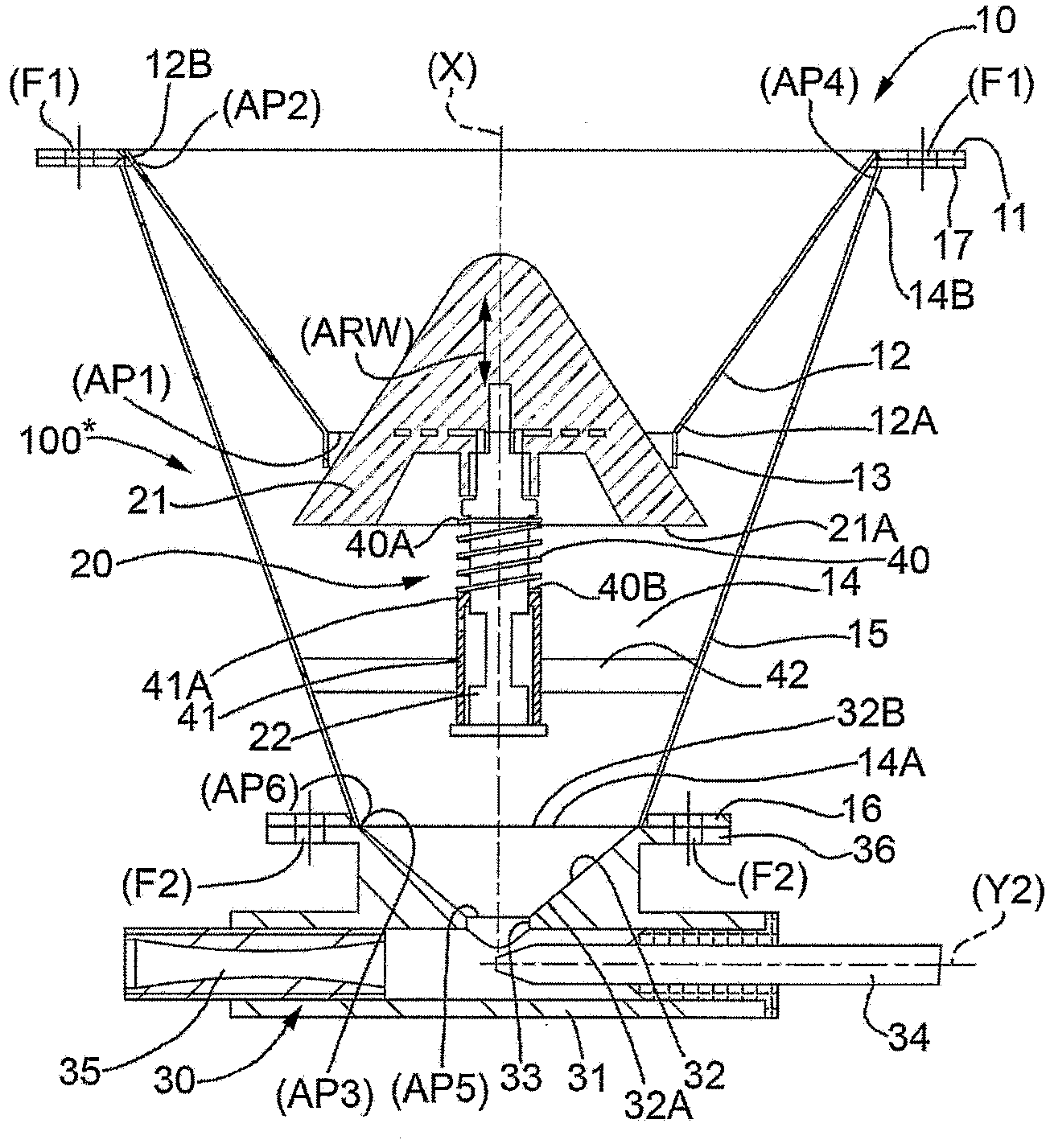

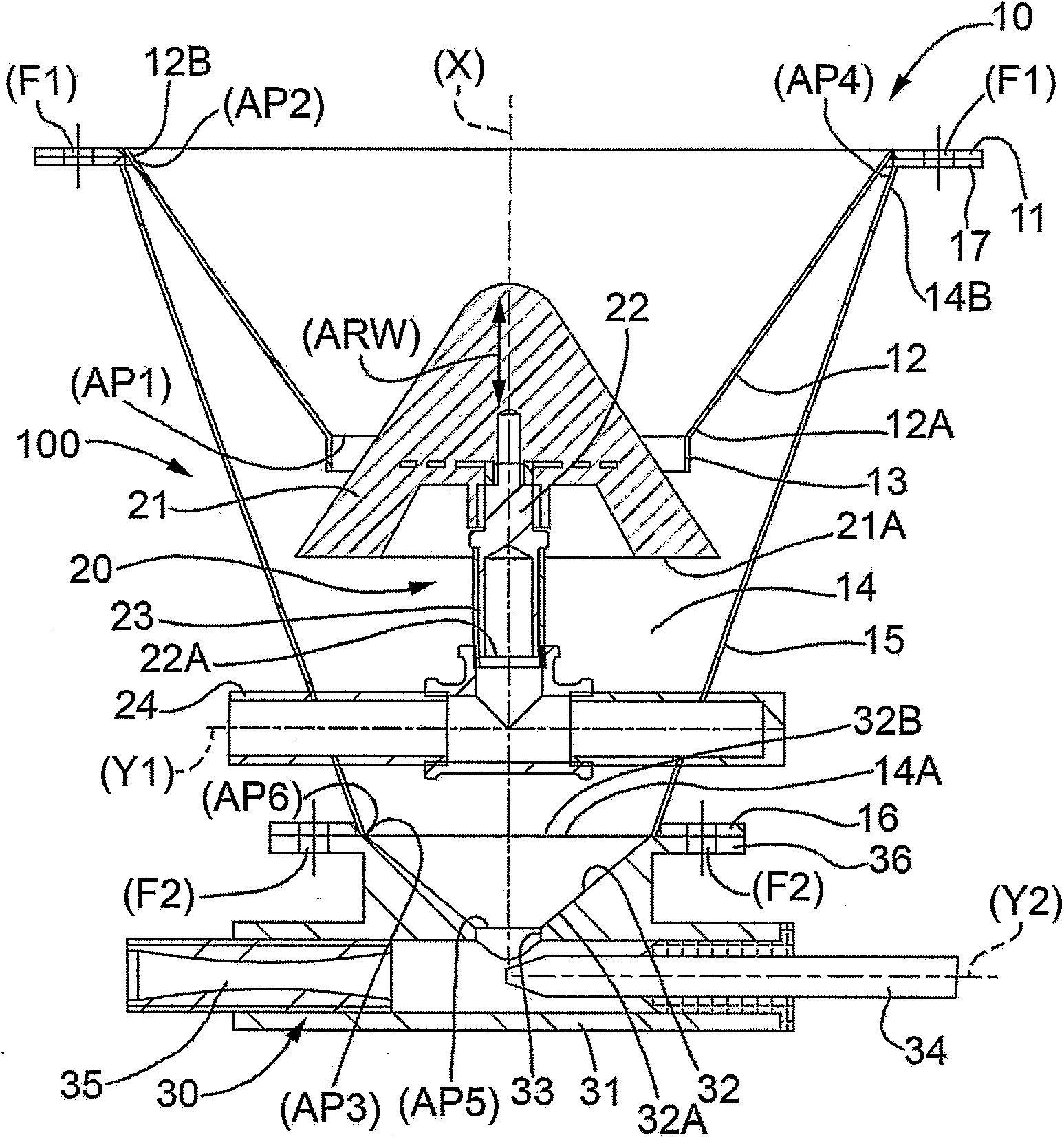

[0020] exist figure 1 In , an innovative pneumatic dust removal device for an overhead filter system 10 is designated as a whole by reference 100 .

[0021] In conventional manner, the filter system 10 comprises a filter (not shown) mounted on the upper flange 11 of a funnel 12 for collecting dust from said filter.

[0022] Such as figure 1 As shown, the funnel 12 has the shape of an inverted frustum, ie the smaller base 12A of the frustum is positioned below the larger base 12B of the frustum.

[0023] At the location of the smaller base 12A there is provided an opening (AP1) through which the dust is discharged from the funnel 12 towards the discharge means (described below).

[0024] Similarly, the upper base features an opening (AP2) which connects the filter and funnel 12.

[0025] Advantageously, said smaller base envisages a cylindrical collar 13 .

[0026] Below and around said funnel 12 there is provided an intermediate chamber 14 which also advantageously but not...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com