Three-dimensional cutting machining method

A cutting and three-dimensional technology, applied in metal processing, metal processing equipment, metal processing mechanical parts, etc., can solve the problem of inability to correct the error of the processing position, and achieve the effect of high-precision correction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

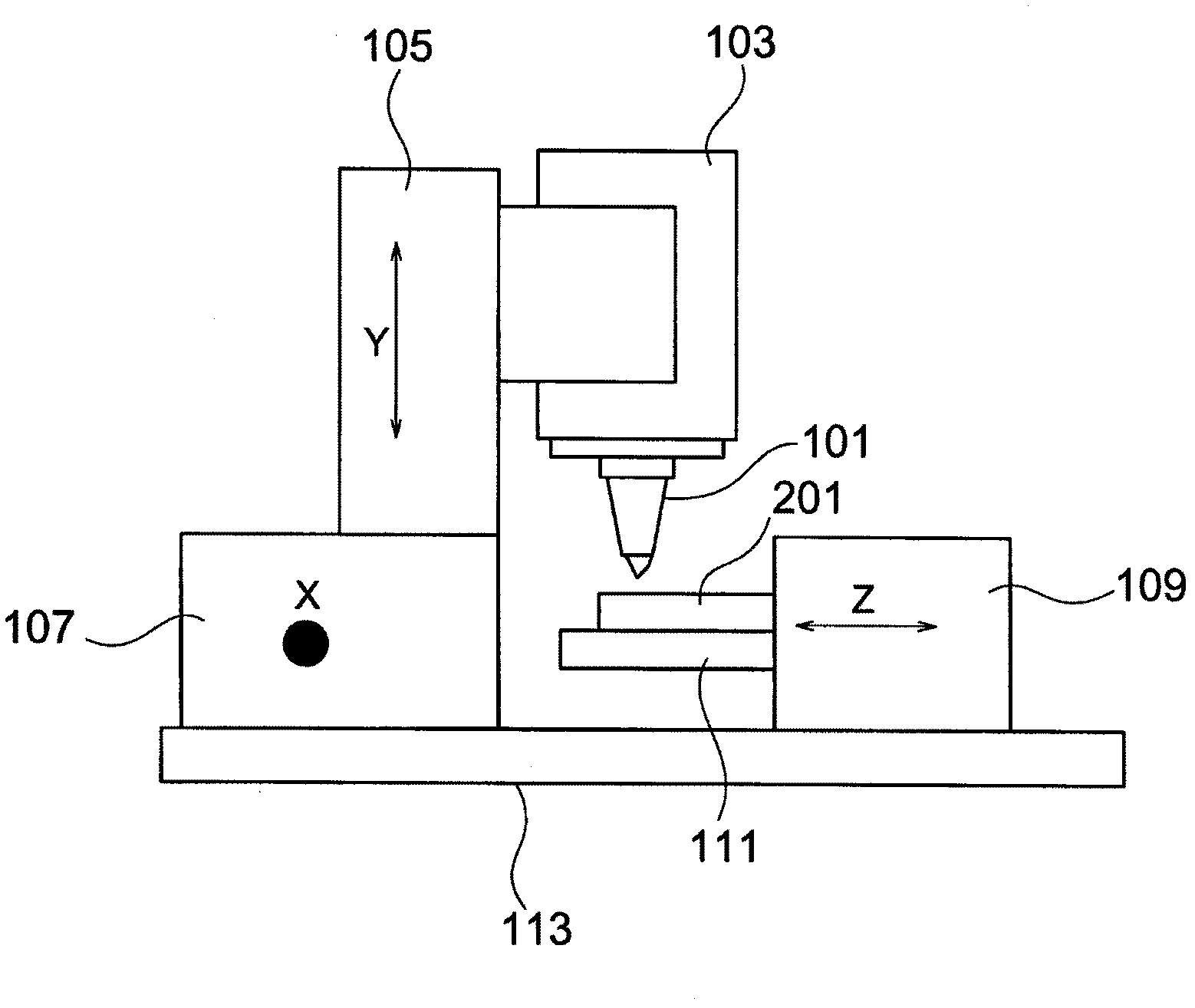

[0038] See figure 1 , the tool 101 of the three-dimensional cutting machine in the present invention is installed on the lifting platform 103 . The lift table 103 is mounted on a base 105 movable in the Y-axis direction (vertical direction). The base 105 is mounted on an X-axis direction moving stage 107 that can move in the X-axis direction. On the other hand, the job 201 is held and sucked on the table 111 by a vacuum fastener or the like. The stage 111 is fixed on a Z-axis direction movable table 109 that can move in the Z-axis direction.

[0039] exist figure 1 In the shown three-dimensional cutting machine, the elevating table 103, the X-axis direction moving table 107, and the Z-axis direction moving table 109 are each configured to be movable in the Y-axis direction, the X-axis direction, and the Z-axis direction. The work held on the movable table moving in the Z-axis direction, as another component of the three-dimensional cutting machine, can be applied to the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com