Waste wood slicing method and machine

A technology for wood and machinery, applied in the field of slicing of waste wood and its machinery, can solve the problems of high unqualified rate, mismatch of raw material size, parallelism error of slicing, and achieve good economic benefits, low cost, The effect of reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

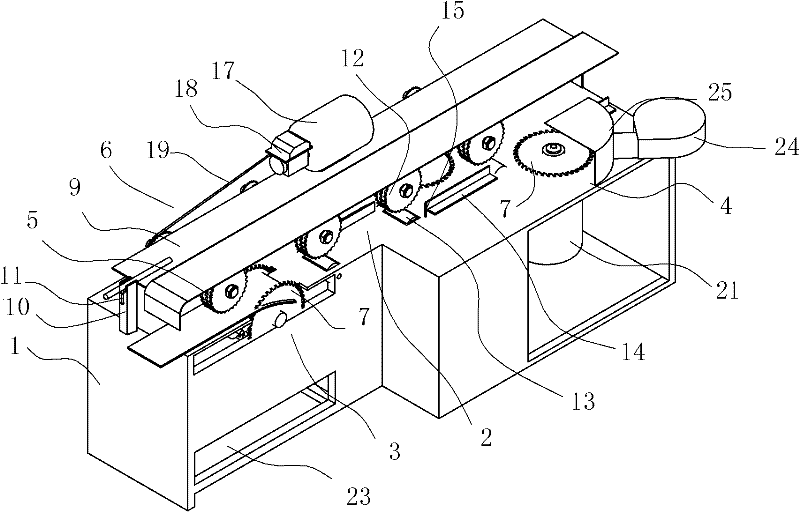

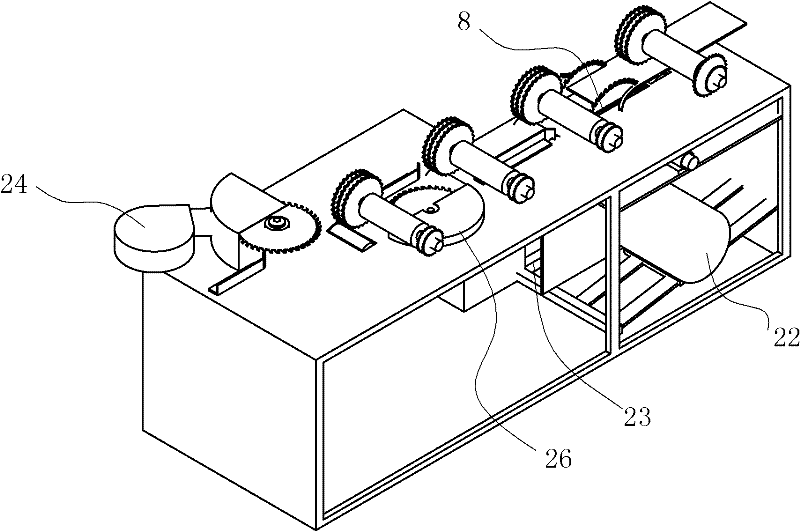

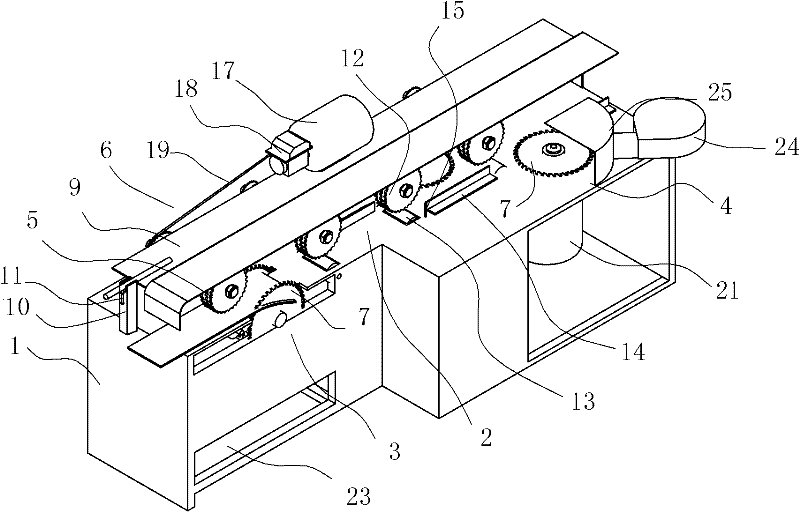

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0022] Example. The cutting method of waste wood, the method feeds waste wood under the push of the conveying device; the longitudinal cutting device uses two saw blades on the vertical working platform to cut the waste wood in the vertical plane; the plane cutting device uses two parallel saw blades The saw blade on the working platform cuts the waste wood in the horizontal plane; then the material is discharged through the conveying device to realize the re-opening of the wood; the conveying device uses the toothed roller fixed on the working platform to rotate against the waste wood to push the waste wood forward ; There is a passively rotating auxiliary roller under the toothed roller to reduce the friction between the waste wood and the working platform.

[0023] In this method, a falling chip room is set under the saw blade of the verti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com