Central control brake system and trolley type movable medical equipment

A central control and braking system technology, which is applied to hospital equipment, trolleys, trolley accessories, etc., can solve the problems of inconvenient and laborious operation, and achieve the effect of convenient operation and labor saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

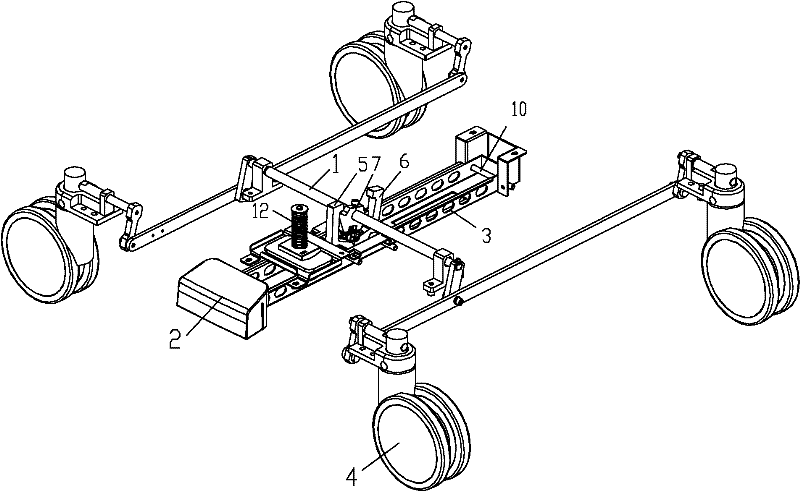

[0031] Please refer to Figure 1 to Figure 3 , The central control brake system of the present embodiment includes a base frame (not shown in the figure), castors 4, brake transmission shaft 1, plate beam 3, pedal 2 and reversing transmission assembly. Wherein, the base frame is connected with the car body, the plate beam 3 and the casters 4 are installed at the bottom of the base frame, and the plate beam 3 is movably connected with the base frame, the pedal 2 is fixed on the plate beam 3, and the reversing rotating assembly connects the plate beam 3 and The brake rotation shaft 1 is used to make the brake drive shaft 1 reversing and rotate under the control of the pedal 2 . The number of casters 4 can be one or more, and the brake transmission shaft 1 is connected with the casters 4 using a connecting rod structure. When the brake transmission shaft 1 rotates forward or reverse under the drive of the reversing rotating assembly, the brakes of the casters 4 are respectively c...

Embodiment 2

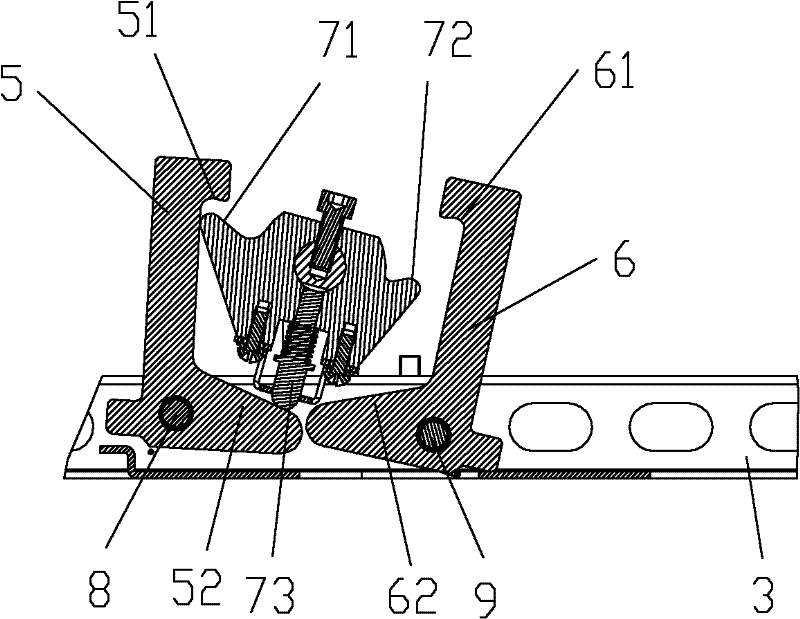

[0035] Please refer to image 3 and Figure 4The upper end of the first reversing hook 5 is provided with a first snapping hook 51, and the lower end is provided with a first resisting portion 52 on the same side as the first snapping hook 51. Correspondingly, the upper end of the second reversing hook 6 is provided with a second snapping hook. Hook 61, the lower end is provided with the second abutting portion 62 on the same side as the second snapping hook 61; The bottom is provided with telescoping rod 73. Before the operator depresses the pedal 2, the reversing rotation assembly is in the first relative position, and the telescopic rod 73 is against the top of the first resisting portion 52. When the operator depresses the pedal 2 and moves it downward for a certain distance, the first reversing member The first engaging hook 51 on the hook 5 engages with the first engaging part 71 on the reversing wheel 7 and rotates synchronously. When the operator releases the pedal 2...

Embodiment 3

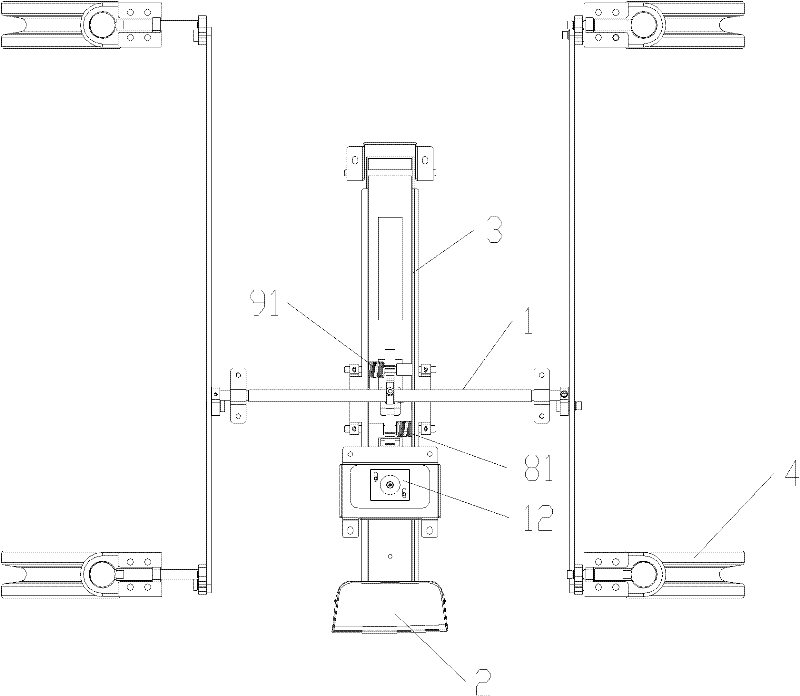

[0041] The connection mode between the plate girder 3 and the base frame, and the positions of the pedal 2, the first reversing hook 5 and the second reversing hook 6 on the plate girder 3 can be determined according to requirements. Figure 5 In the illustrated embodiment, one end of the plate girder 3 is rotatably connected to the base frame through the base frame rotating shaft 10, the other end is fixed to the pedal 2, and the first reversing hook 5 and the second reversing hook 6 are rotatably connected to the middle part of the plate girder 3. The plate girder 3 is relatively long. When the operator steps on the pedal 2, the entire plate girder 3 drives the reversing wheel 7 to rotate a certain angle through the first reversing hook 5 or the second reversing hook 6, so that the pedal 3 can be turned downward. Move a larger distance to realize the conversion of the reversing rotating assembly to different states. Therefore, the motion track of the pedal 2 is close to a str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com