Novel monolithic beam of heavy dumper back balance shaft

A dump truck and post-balancing technology, which is applied to vehicle parts, substructure, transportation and packaging, etc., can solve the problems of heavy weight, high manufacturing cost, and many consumables, and achieve the effect of reducing quality and production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

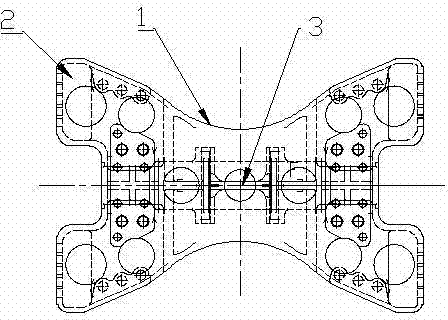

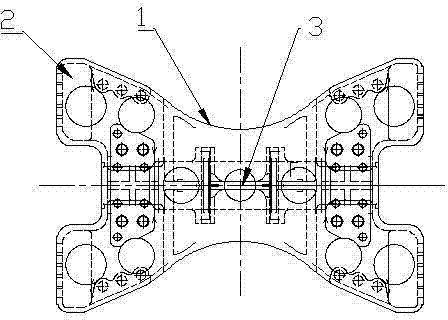

[0007] Such as figure 1 As shown, the beam main body 1, the mounting seat 2, and the reinforcing rib 3 are included.

[0008] The four corners of the beam body 1 are provided with mounting seats 2, and the side walls and bottom of the mounting seat 2 are provided with mounting holes. The center of the beam body 1 is provided with reinforcing ribs 3 along the longitudinal direction. The beam body 1, the mounting seat 2, and the reinforcing ribs 3 are integral Cast into a shell-shaped body.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com