Hydraulically driven grille type gate valve

A gate valve and hydraulic technology, applied in the field of grid gate valve, can solve the problems of poor gate sealing, slow opening and closing speed, short opening and closing speed, etc., and achieve the effect of sealing without dust leakage, low cost and good sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

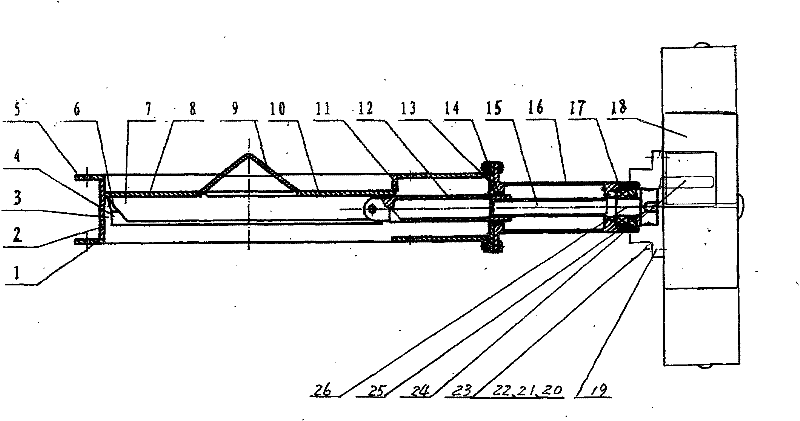

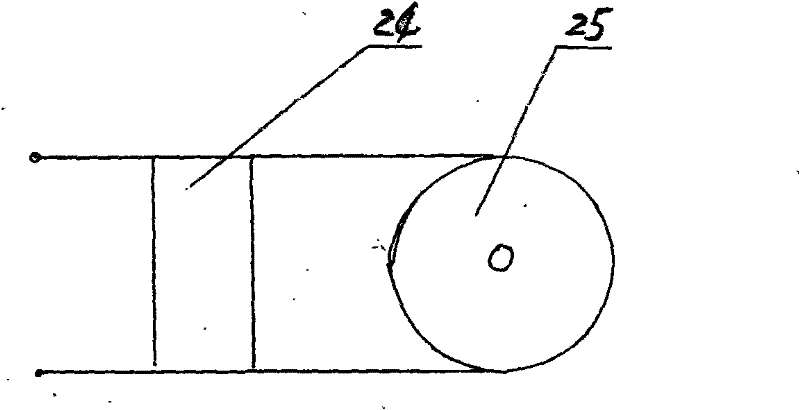

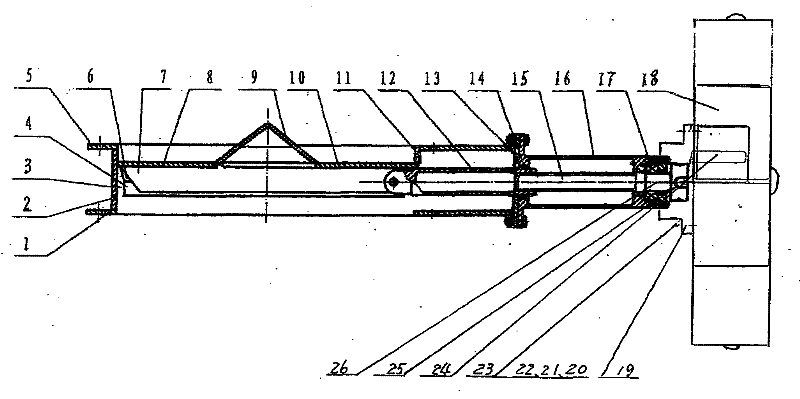

[0010] In the figure, the opening and closing of the gate valve is controlled by a hydraulic drive device. The hydraulic driving device drives the screw supported by the bearing and axially positioned to rotate. When the rotating direction of the hydraulic driving device makes the screw sleeve spin away from the screw rod, the screw sleeve hinged with the gate will push the gate to slide to the closed state. When the gate is far away The small gate at the end of the gate is pressed against the end plate, and the lower part of the grill just covers the space of the gate. The upper and lower passages of the valve body are all blocked, and the gate valve is in a closed state. When the hydraulic drive head rotates in the reverse direction, the screw rod and the screw sleeve are screwed together, and the screw sleeve pulls the ram to slide toward the open state. Under the grid and between the small end plate and the end flange of the gate plate, the channel space originally blocke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com