Photocurable polysiloxane component and substrate protective film formed by the same

A technology of polysiloxane and light hardening, applied in optics, nonlinear optics, instruments, etc., can solve the problems of poor developability and uneven film thickness, and achieve the effect of good developability and uniform film thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

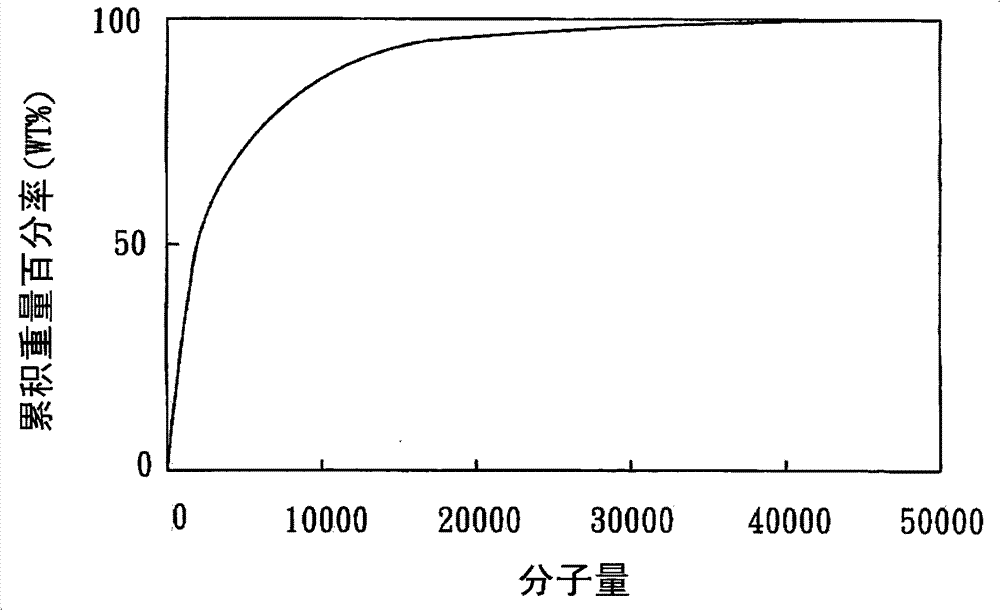

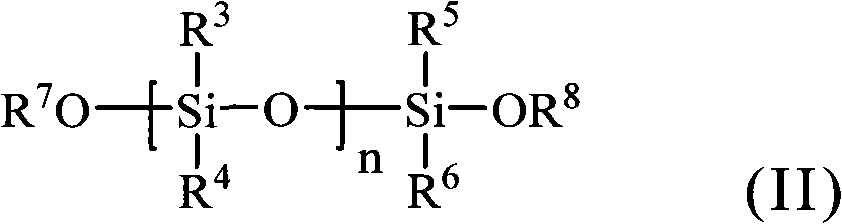

preparation example 1

[0099] In a three-necked flask with a volume of 500 milliliters, 84 grams (0.7mol) of dimethyldimethoxysilane (abbreviated as DMDMS), 59.4 grams (0.3mol) of phenyltrimethoxysilane (abbreviated as PTMS) and propylene glycol mono Diethyl ether (referred to as PGEE) 180 grams, and while stirring at room temperature, add oxalic acid aqueous solution (0.20 grams of oxalic acid / 30 grams of H 2 O). Next, immerse the flask in an oil bath at 30°C and stir for 30 minutes, then raise the temperature of the oil bath to 120°C within 30 minutes, and when the internal temperature of the solution reaches 105°C, continue heating and stirring for polycondensation for 2 hours. Polysiloxane polymer (A-1) was obtained. During the reaction, 73 grams and 17 grams of by-products such as methanol and water were distilled off respectively.

preparation example 2

[0101] In a three-necked flask with a capacity of 500 ml, 84 grams (0.7 mol) of dimethyldimethoxysilane, 59.4 grams (0.3 mol) of phenyltrimethoxysilane and 180 grams of propylene glycol monoethyl ether were added, and at room temperature While stirring, add oxalic acid aqueous solution (0.3 g oxalic acid / 30 g H 2 O). Next, immerse the flask in an oil bath at 30°C and stir for 30 minutes, then raise the temperature of the oil bath to 120°C within 30 minutes, and when the internal temperature of the solution reaches 110°C, continue heating and stirring for polycondensation for 3 hours. Polysiloxane polymer (A-2) was obtained. During the reaction, 73 grams and 18 grams of by-products such as methanol and water were distilled off respectively.

preparation example 3

[0103]In a three-necked flask with a volume of 500 ml, add 72 grams (0.6 mol) of dimethyldimethoxysilane, 88.8 grams (0.37 mol) of phenyltriethoxysilane (abbreviated as PTES), and "DMS-S27" 540 grams (0.03mol) and 180 grams of propylene glycol monoethyl ether, and while stirring at room temperature, add oxalic acid aqueous solution (0.20 grams of oxalic acid / 30 grams of H 2 O). Next, immerse the flask in an oil bath at 30°C and stir for 30 minutes, then raise the temperature of the oil bath to 120°C within 30 minutes, and when the internal temperature of the solution reaches 105°C, continue heating and stirring for polycondensation for 2 hours. Polysiloxane polymer (A-3) was obtained. During the reaction, 57 grams, 48 grams and 26 grams of by-products such as methanol, ethanol and water were distilled off respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com