Snow pusher of skid steer loader

A skid steer loader and snow pusher technology, applied in snow surface cleaning, construction, cleaning methods, etc., can solve problems such as hindering the forward movement of the skid steer loader, and achieve the effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

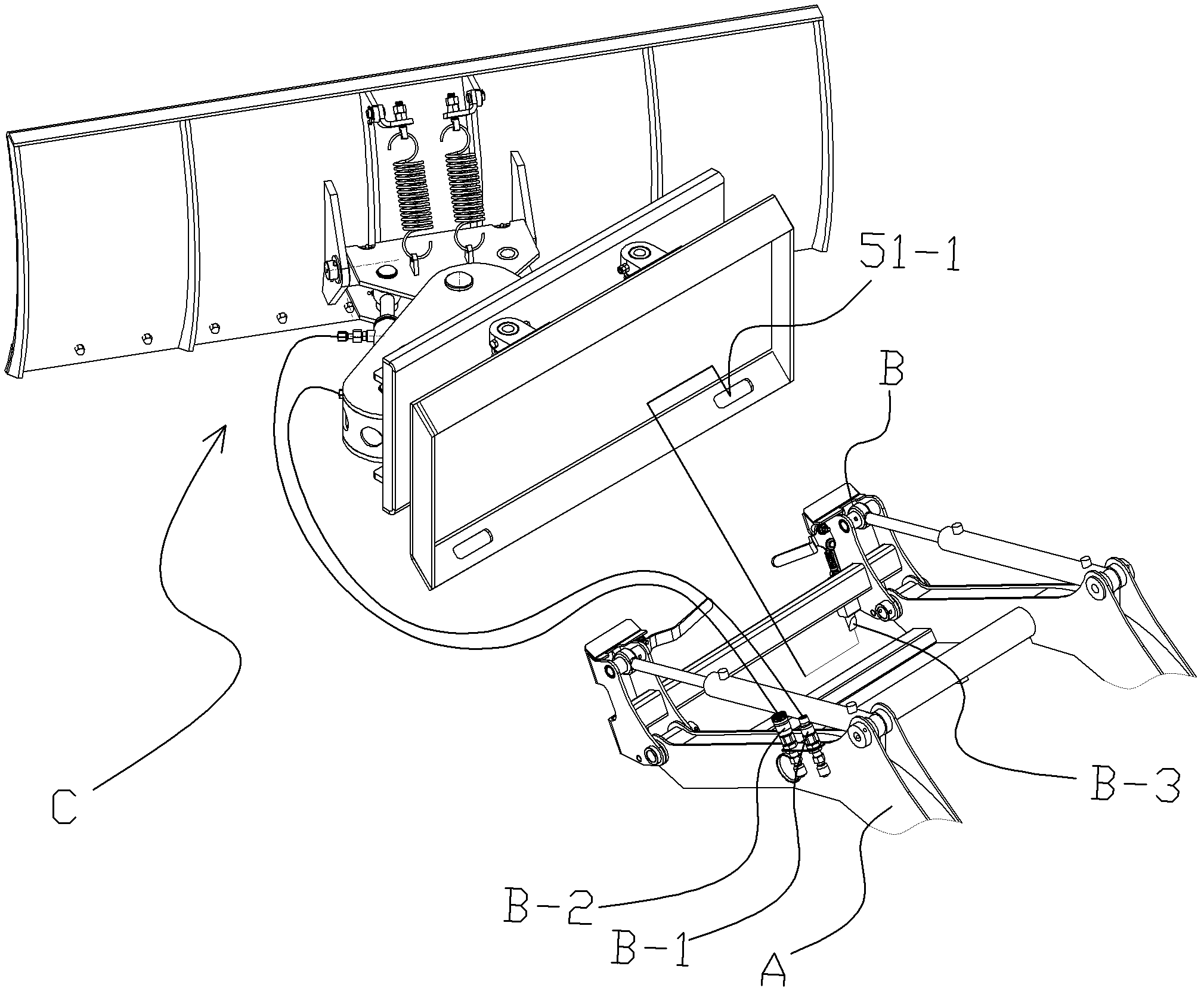

[0035] see Figure 1-12 , the front loading arm of the skid steer loader A is equipped with a mechanical quick-change joint B, and two hydraulic quick-change joints B-1 and B-2 are installed on the mechanical quick-change joint B. The mechanical quick-change joint B is detachably connected to the snow pusher C, and the matching structure of the two is described below.

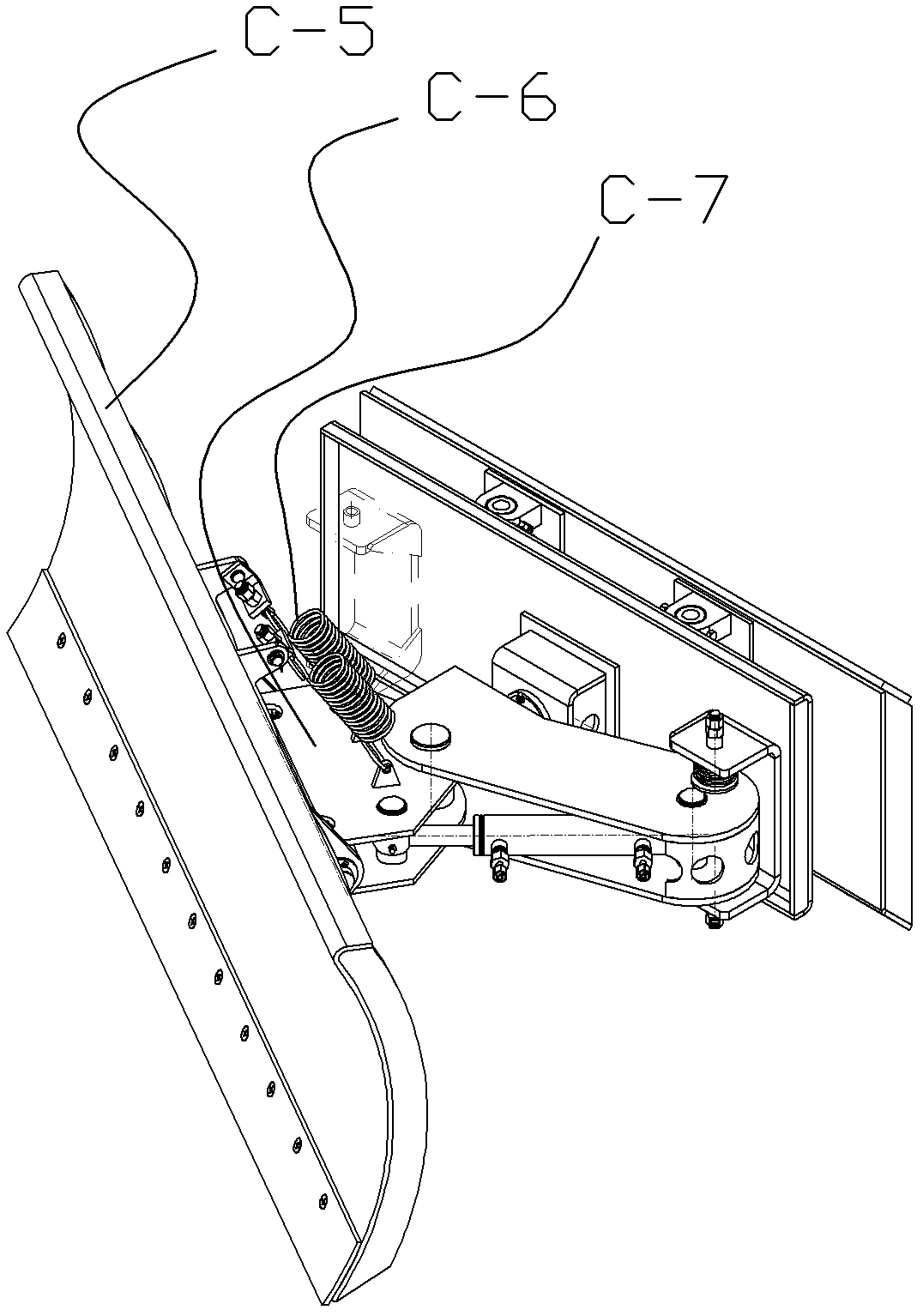

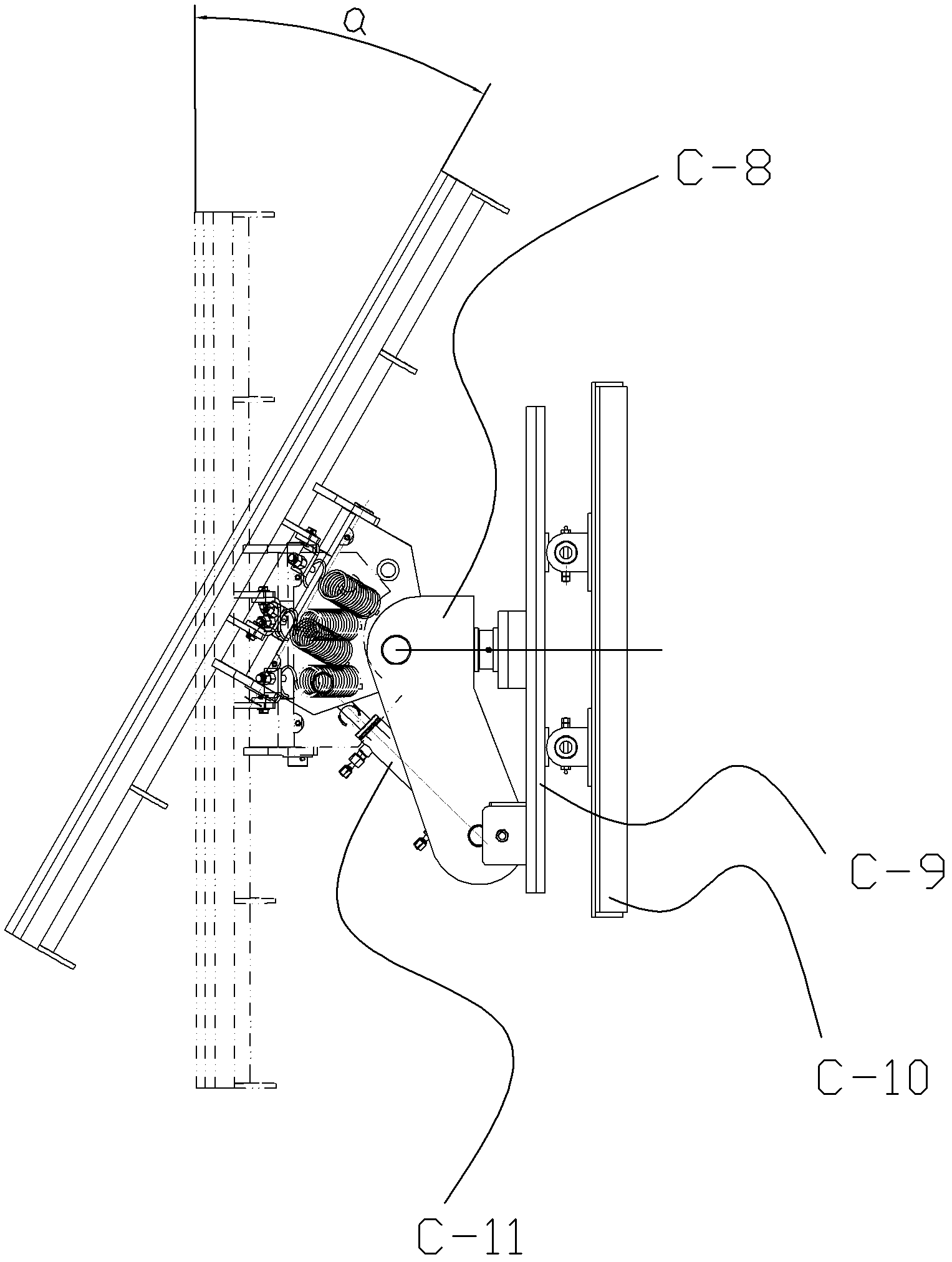

[0036] Snow pusher C includes snow pusher assembly C-5, support frame assembly C-6, tension spring mechanism assembly C-7, yaw frame assembly C-8, transition frame assembly C-9, hanger Assembly C-10, hydraulic cylinder installation assembly C-11. Each part of the snow pusher is described in detail below.

[0037] see Figure 5 The welded push plate 1 is made of a steel plate rolled into an arc shape, bent, reinforced and welded, and processed. The lower part of the front (the snow p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com