Combined mixed-discharge technology for mining barren rock soil and solidified tailings

A technology for mining waste rock and tailings, applied in excavation, construction, infrastructure engineering, etc., can solve problems such as endangering the safety of personnel and equipment, affecting the normal production of open pits and dumps, etc., to save infrastructure costs, directly The effect of significant economic benefits and huge social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

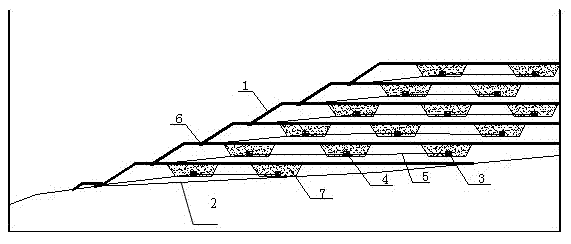

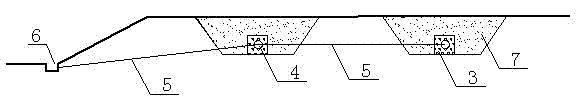

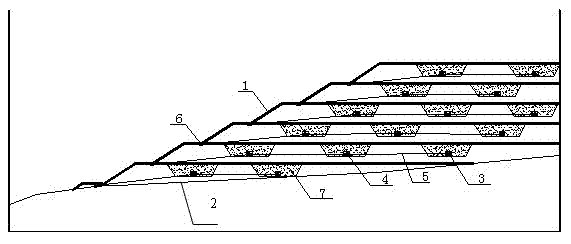

[0028] In order to further describe the present invention, a joint mixing technology of mining waste rock soil and solidified tailings of the present invention will be further described in detail below in conjunction with the accompanying drawings and examples.

[0029] figure 1 Shown in the present invention is a longitudinal projection of a mining waste rock soil and solidified tailings in a combined mixed-discharge dump in a dump site and combined figure 2 It can be seen from the detailed picture of solidified tailings stacking that the solidified tailings 7 are designed as a trapezoidal structure with a narrow bottom and a wide upper part, and are arranged in each platform body of the dump according to a certain distance; 1 is provided with intercepting ditches 6 at the bottom; a drainage blind ditch 3 is set at the bottom of the solidified tailings 7, and seepage drainage flower pipes 4 are buried in the drainage blind ditch 3, and the outlets of the seepage drainage flo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com