Pneumatic reversing valve

A technology of air-controlled reversing valve and reversing valve, which is applied in the direction of fluid pressure actuators, servo motor components, fluid pressure actuation system components, etc., which can solve the problems of large size, difficult transportation, heavy weight, etc. The effect of volume, saving installation pipeline and short working time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with specific embodiments and accompanying drawings.

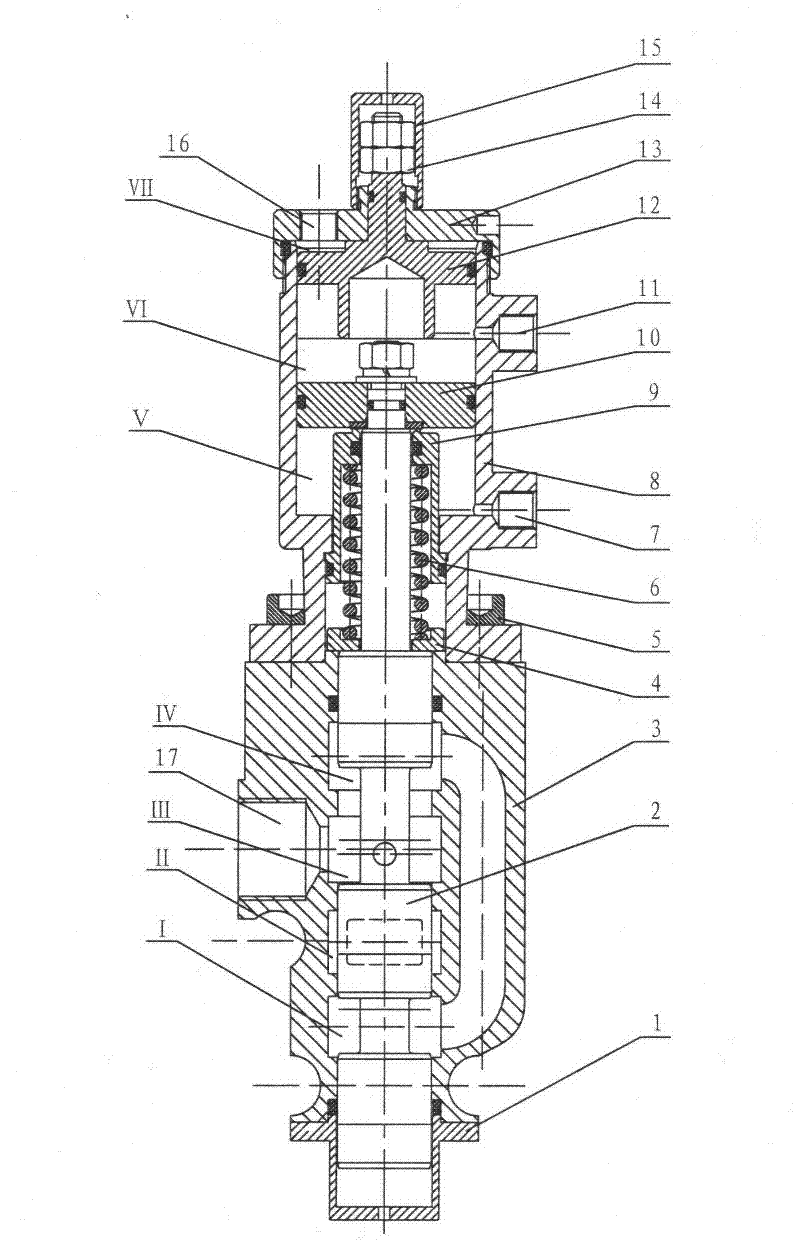

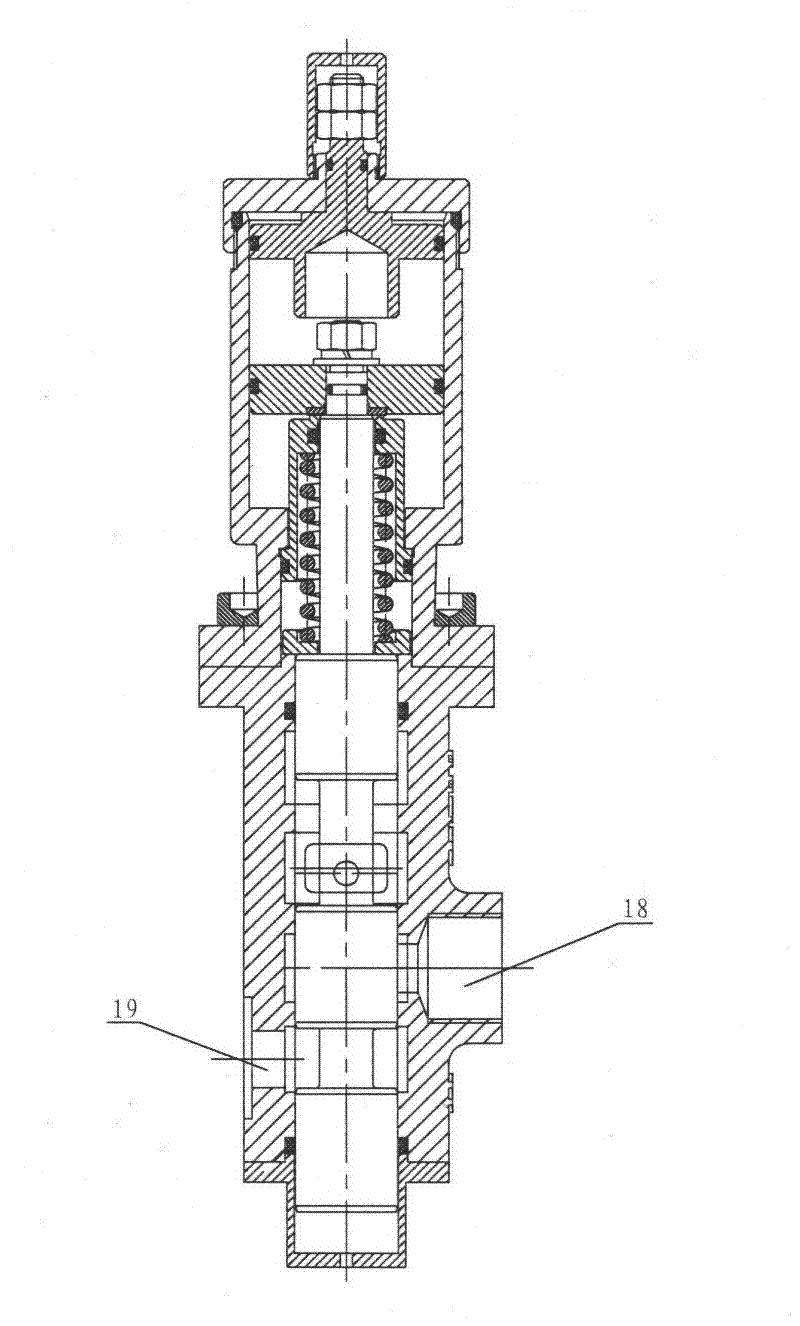

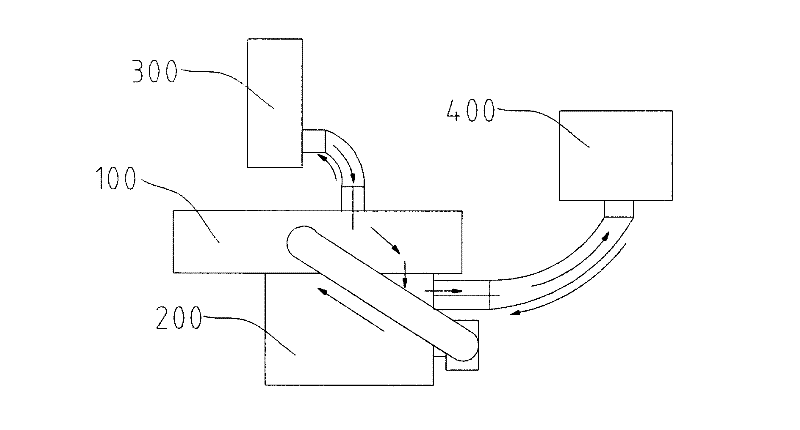

[0022] See Figure 1 to Figure 3 , the air-controlled reversing valve includes a valve body 3, a cylinder 8 and a mandrel 2, the valve body 3 is fixedly connected to the cylinder 8, and has a slide valve hole communicating with the valve body 3 and the cylinder 7 , the mandrel 2 is slidably arranged in the spool hole, and a return spring 6 is arranged on the mandrel 2;

[0023] Oil return chambers I, IV, oil outlet chamber II, and oil inlet chamber III are formed between the mandrel 2 and the valve body 3, and the valve body 3 is respectively provided with an oil return port 19, an oil outlet port 18, and an oil inlet chamber. The port 17 corresponds to the oil return chamber I, the oil outlet chamber II and the oil inlet chamber III one by one;

[0024] The mandrel 2 divides the interior of the cylinder 8 into two air chambers V, VI th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com