Vibration exciter for NVH (Noise Vibration and Harshness) test and application method thereof

A vibration exciter and excitation technology, applied in the field of NVH testing, can solve the problems of complex operation, low vibration exciter spring stiffness, high equipment requirements, etc., and achieve the effect of flexible and convenient operation, low production cost and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

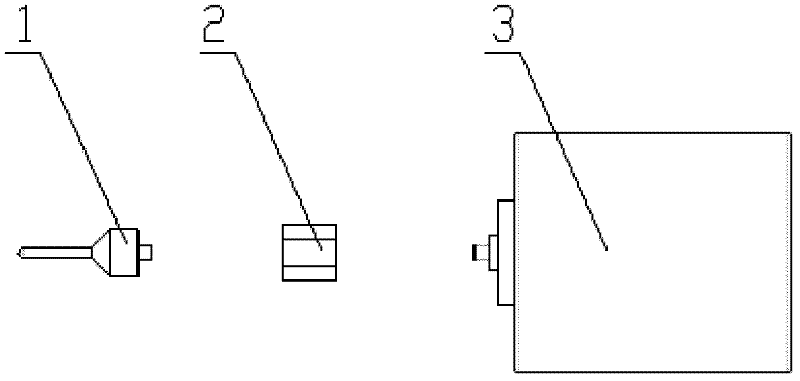

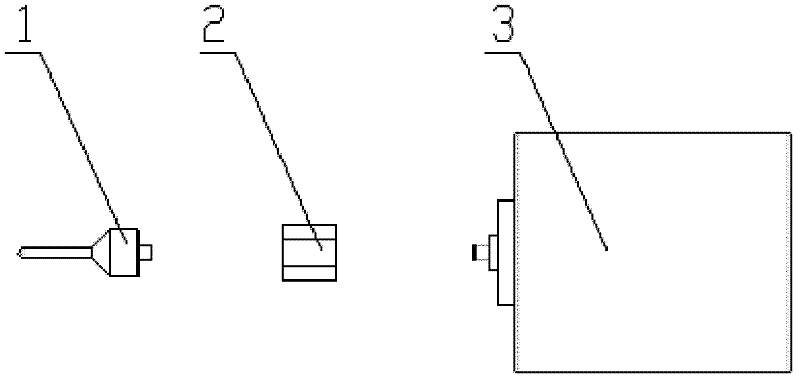

[0016] Such as figure 1 As shown, the present invention is that the vibrator body 3 is connected to the vibrating head 1 through the force sensor 2, so that the vibrator body 3 vibrates the excited parts through the vibrating head 1, reducing the distance between the vibrator and the excited parts. distance requirements.

[0017] The excitation head 1 is a conical structure with a thin cylindrical head and a conical bottom, which can prevent uneven force on the contact surface when contacting the excited part, and can increase the friction with the excited part. Prevents slipping during vibration. Both ends of the force sensor 2 are provided with threaded holes, which are respectively connected to the exciter body 3 and the exciter head. The exciter body 3 reduces the amplitude of the exciter by increasing the spring stiffness of the exciter body 3, so that the exciter head 1 installed on the exciter can directly contact the excited part to vibrate.

[0018] The vibrator of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com