Rubber frame of liquid crystal display

A liquid crystal display, plastic frame technology, applied in the field of plastic products, can solve the problems of expansion deformation, finished product WAVING and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

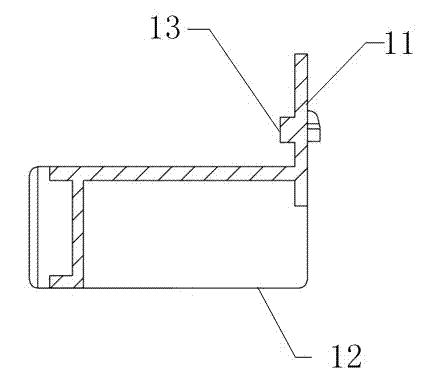

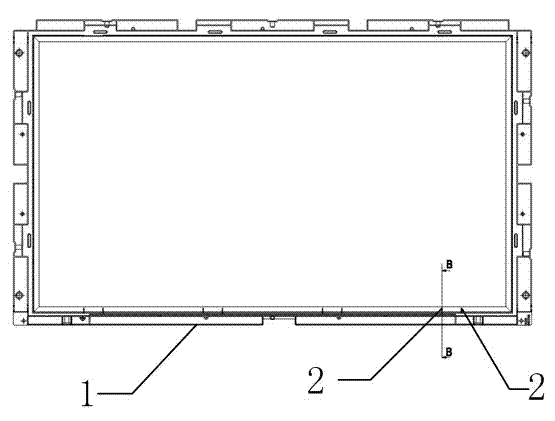

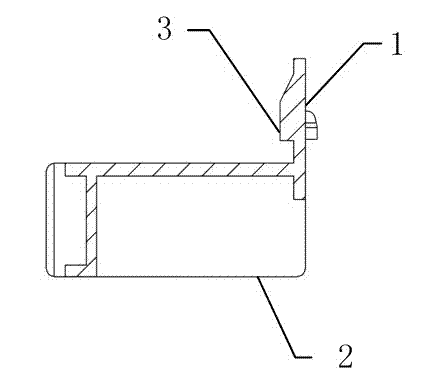

[0013] A kind of liquid crystal display rubber frame of the present embodiment, such as figure 2 with image 3 As shown, it includes a frame-shaped plastic frame body 1. A number of vertically inwardly extending ribs 2 are provided on the inner side of a frame of the plastic frame body 1, and each rib 2 is provided with a protrusion on one side of the plastic frame body 1. Block 3, the side of the bump 3 facing the plastic frame body 2 is a slope with an inverted C angle.

[0014] In this embodiment, the ribs of the rubber frame of the liquid crystal display are designed as an inclined surface with an inverted C angle. This inclined surface can have a slope surface when the diaphragm is pressed, so that it will not interfere with the expansion sheet during assembly, and the expansion sheet will be lifted. It caused expansion deformation and WAVING phenomenon in the finished product, and the defect rate was improved from 1.58% before the design change to 0.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com