A wire bonding fixture

A wire bonding and fixture technology, which is used in the manufacture of electrical components, electrical solid-state devices, semiconductor/solid-state devices, etc., can solve the problems of difficult to guarantee welding quality, poor chip consistency, low equipment utilization, etc. Improve consistency and ease of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

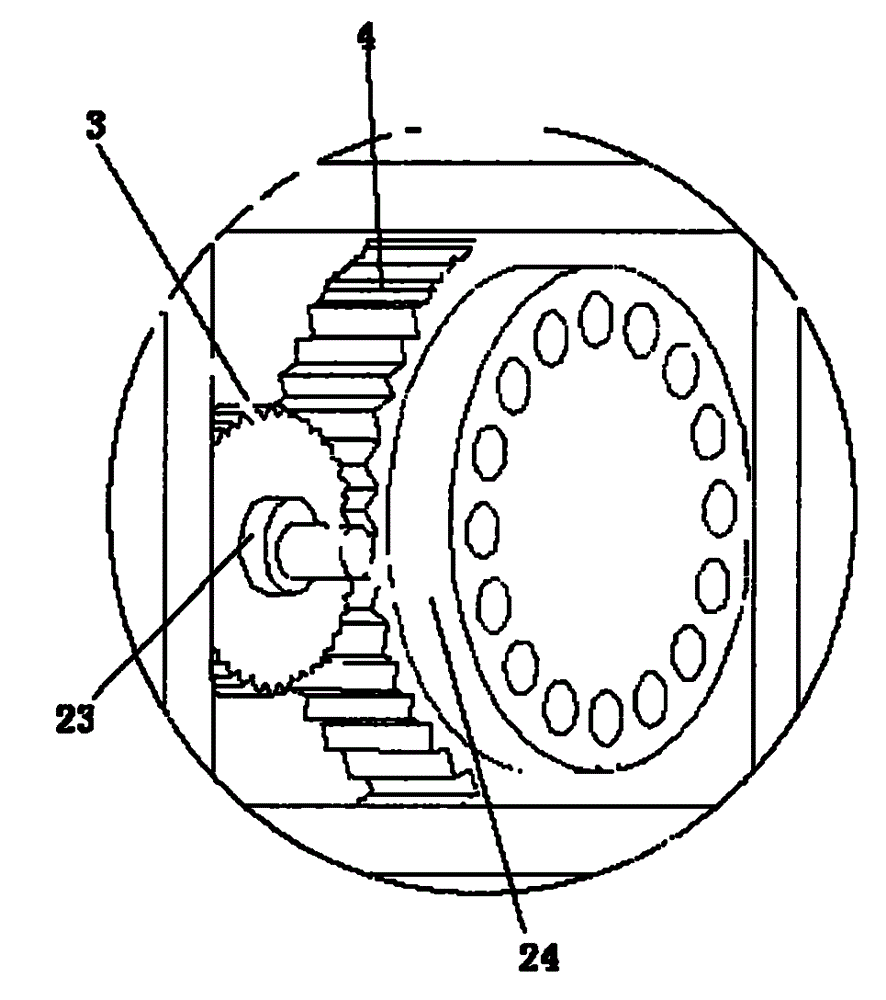

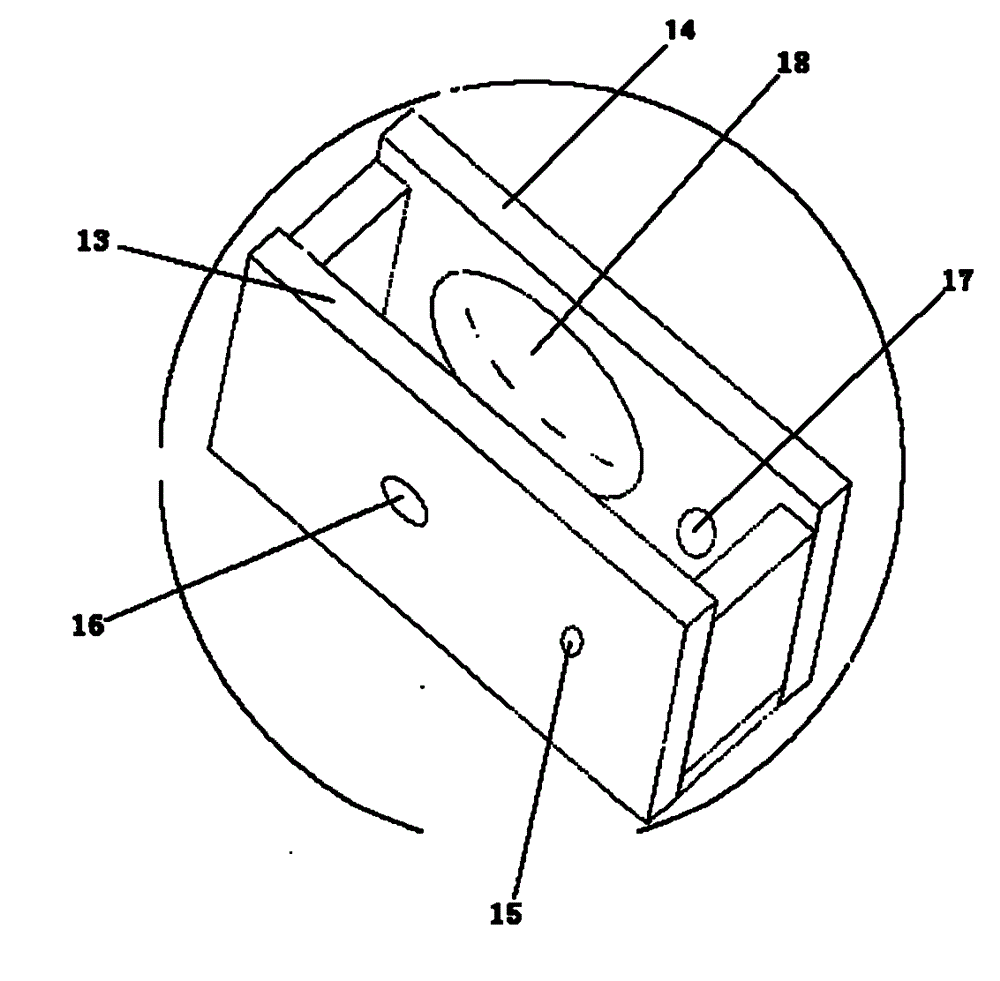

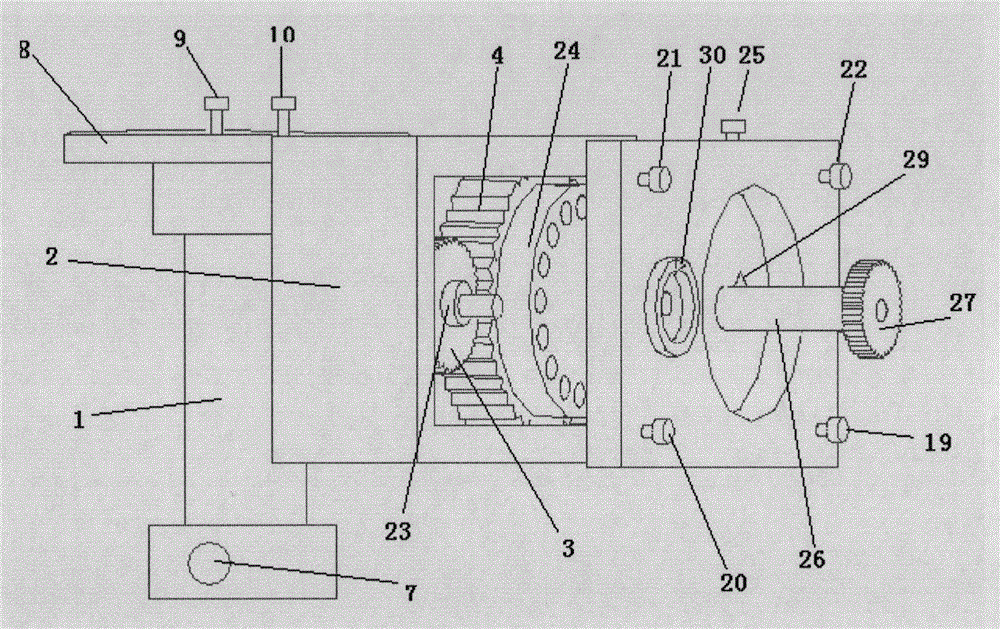

[0024] The invention designs a reasonable clamp structure. By adding a gear box in the clamp, the meshing of large and small gears is used to realize continuous switching of multiple sides in the three-dimensional space of the device. In addition, the present invention connects the fixed shaft with the gear box through the right-angle steering plate, so that the working direction of the clamp is horizontal, which is more convenient for operation. In the selection of the fixing method, the present invention mainly adopts the method of combining the socket fixing and the screw fixing, thereby improving the precision of the bonding. Such as figure 1 As shown, the core components of the present invention include a fixed shaft 1, a gear box 2, a small gear 3, a large gear 4, a small shaft 5, and a large shaft 6; Figure 5 As shown, there is a through hole in the fixed shaft 1 for connecting with the equipment workbench. The two ends of the fixed shaft 1 have integrally formed circula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com