Spot light source and bulb-type light source

A point light source and halogen bulb technology, applied in the field of point light source and bulb-shaped light source, can solve the problem that LED lighting devices are not suitable for halogen bulbs, and achieve the effect of improving heat dissipation efficiency and high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] Embodiments of the present invention will be described in detail with reference to the drawings.

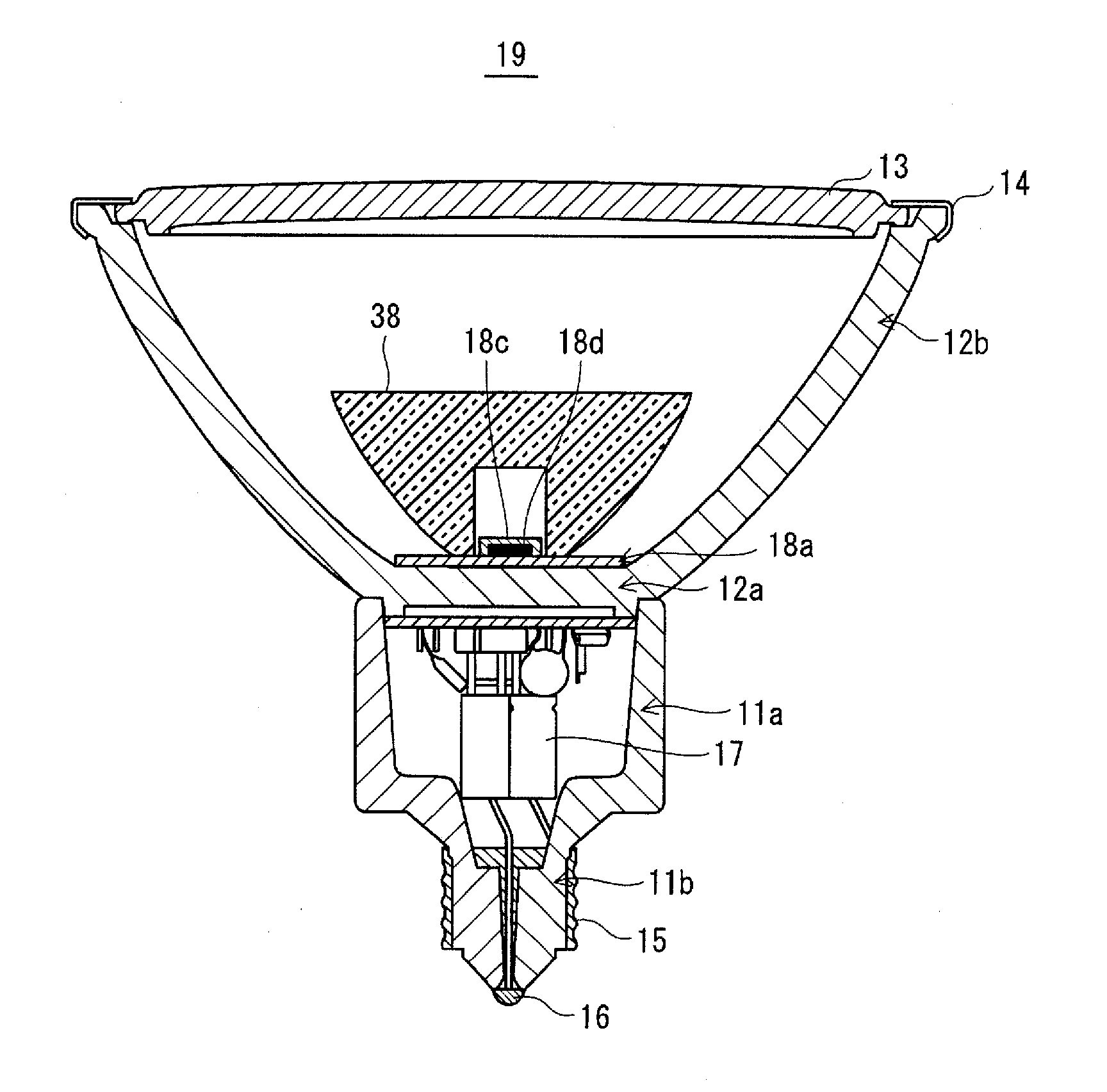

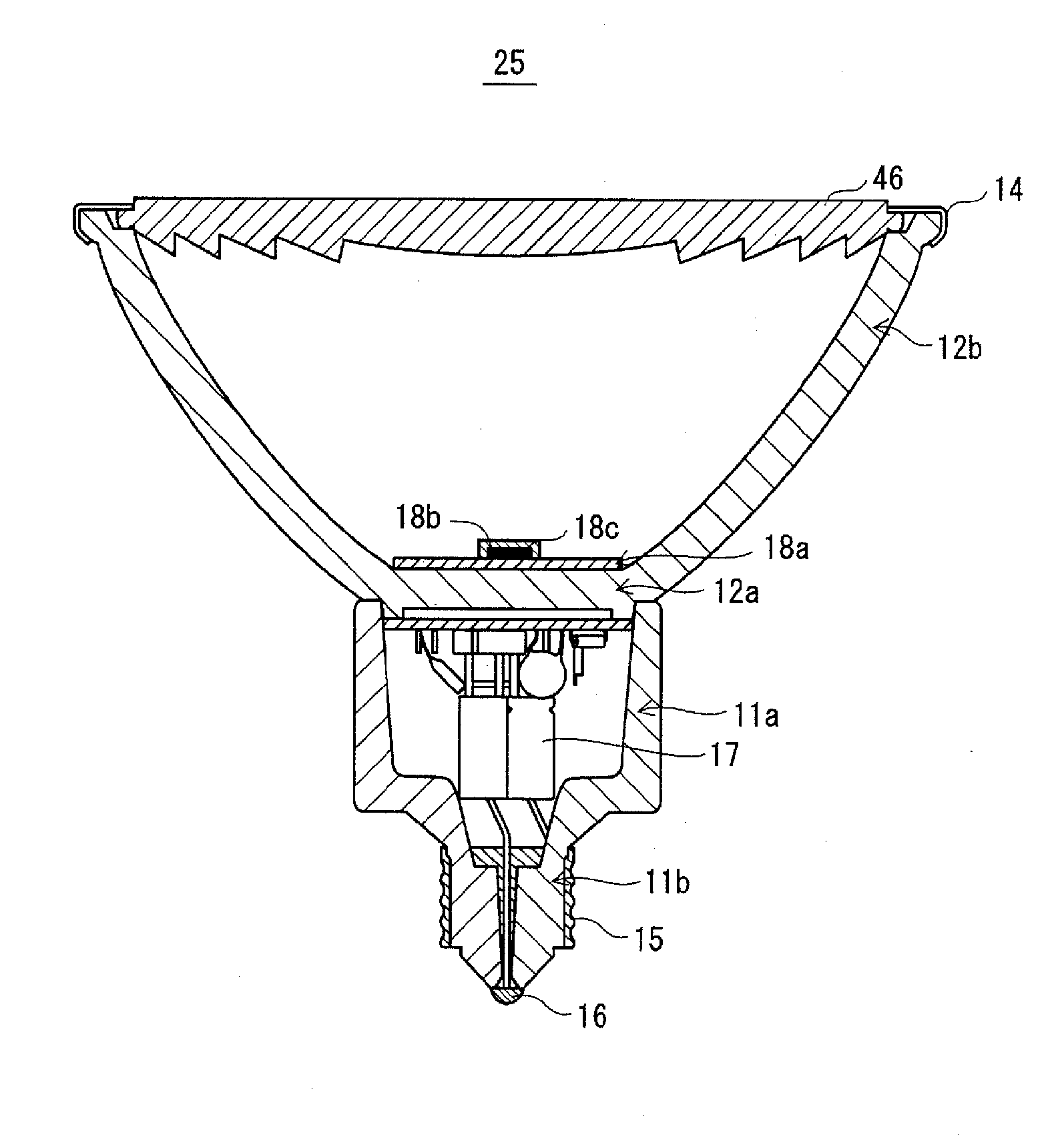

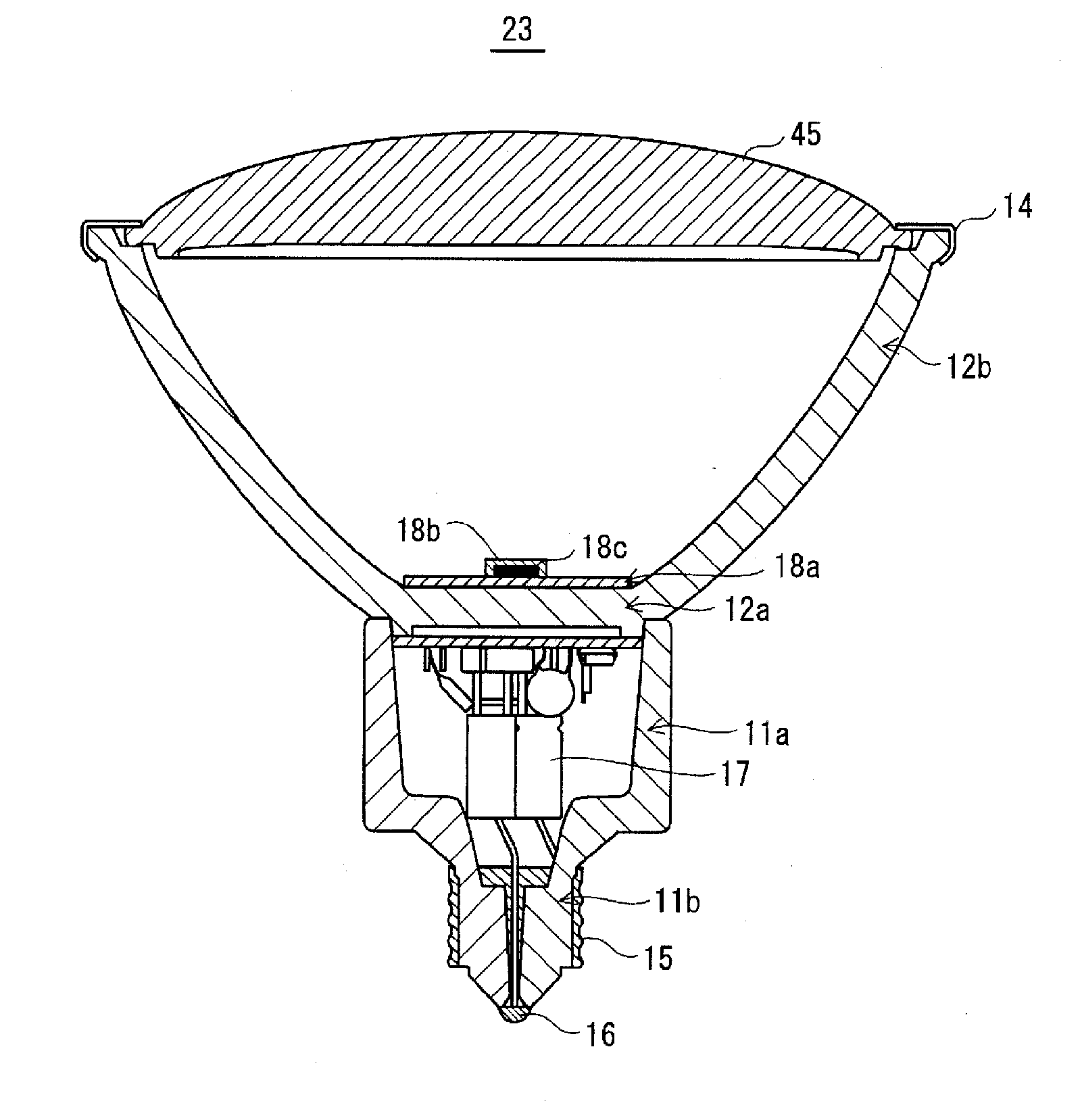

[0074] figure 1 It is a partially cutaway view showing the structure of the point light source according to the embodiment of the present invention.

[0075] The main structure of the point light source 1 includes a housing 11 , a heat sink 12 and a light emitting part 18 . First, the schematic structure of these components will be described, and then the detailed structure of the heat sink 12 will be described.

[0076]

[0077] The housing 11 is made of an insulating material such as ceramics, and includes a cylindrical portion 11a and a protrusion 11b extending from one end of the cylindrical portion 11a. A lighting circuit 17 is housed in the inner space of the cylindrical portion 11a. A metal shell 15 is provided on the outer peripheral surface of the protruding portion 11b, and a metal eyelet 16 is provided on the front end portion of the protruding portion 11b....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com