Environment-friendly road microcapsule, preparation method thereof and application of swill-cooked dirty oil

A microcapsule and environment-friendly technology, applied in the field of environment-friendly road microcapsules and their preparation, can solve the problems of low coating rate, great influence on the performance of asphalt pavement, thickness of the capsule wall, etc. Core coverage and particle size reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

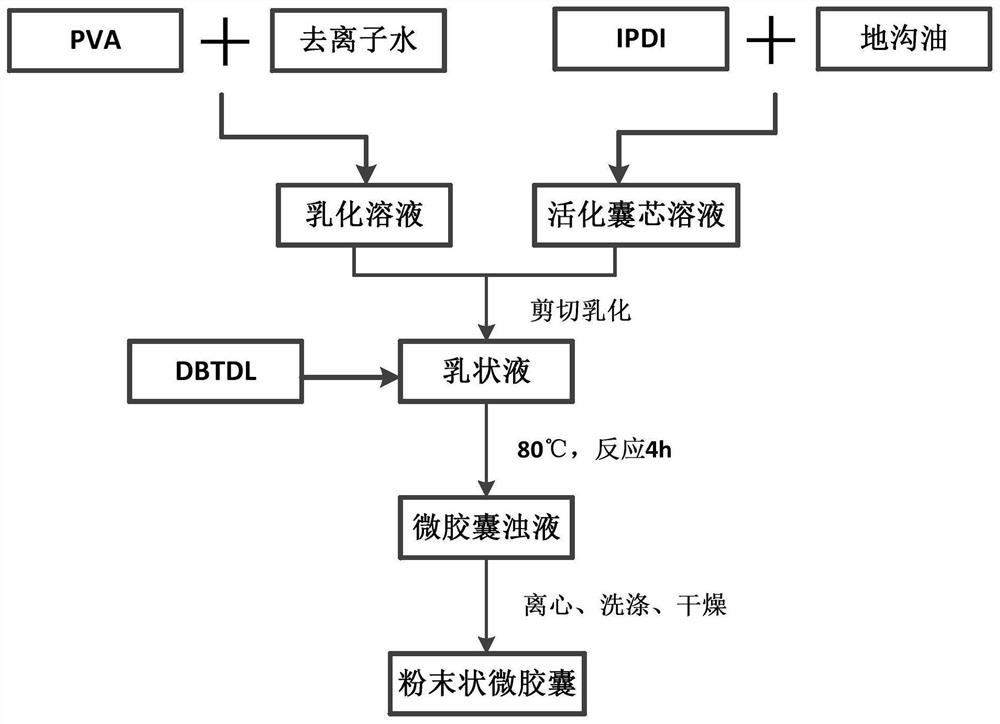

[0033] Such as figure 1 As shown, the present invention prepares the preparation method of above-mentioned a kind of environment-friendly road microcapsules, comprises the following steps:

[0034] Step 1, preparing an emulsifier solution; mixing waste oil and isophorone diisocyanate to obtain an activated capsule core solution;

[0035] Step 2, shearing and mixing the emulsifier solution and the activated capsule core solution to obtain an oil-in-water emulsion;

[0036] Step 3, adding dibutyltin dilaurate dropwise to the oil-in-water emulsion to carry out catalytic emulsification reaction to obtain the cloudy liquid of environment-friendly road microcapsules; centrifuging and drying the cloudy liquid of environment-friendly road microcapsules , to obtain environment-friendly road microcapsules.

Embodiment 1

[0038] An environment-friendly road microcapsule, the proportions of various substances are as follows, PVA: waste oil: IPDI: deionized water = 300: 175: 75: 450, and the amount of DBTDL added is 10% of the mass of IPDI. refer to figure 1 , its preparation method comprises the following steps:

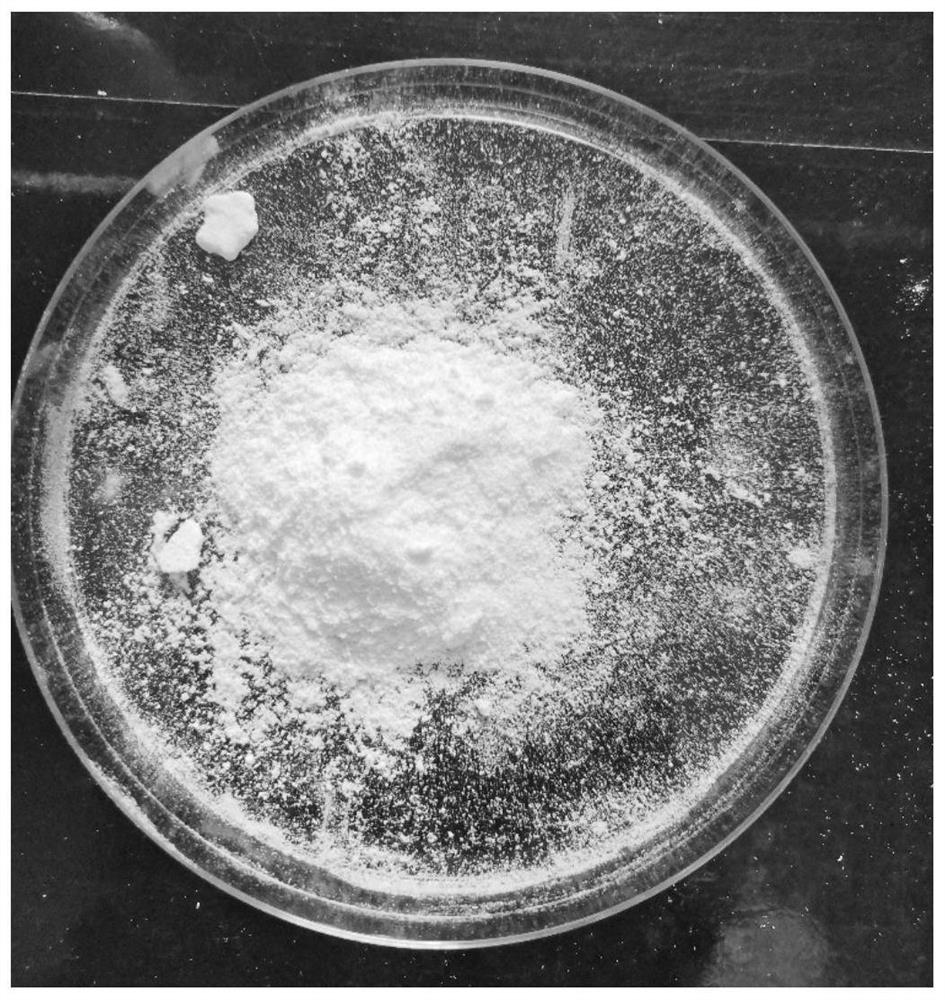

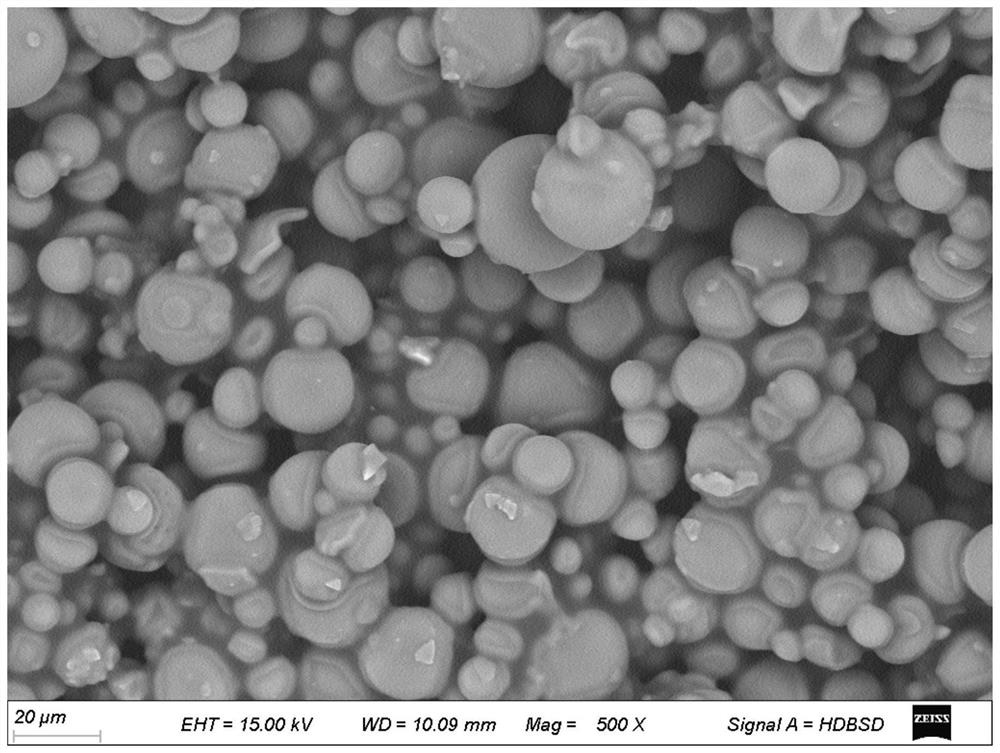

[0039] Get 33.3g of 1788 type liquid PVA, drop it into 50g of deionized water, prepare emulsifier solution; mix 19.4g waste oil with 8.3g isophorone diisocyanate, prepare activated capsule core solution; mix emulsifier solution with The activated capsule core solution was mixed, and high-speed shearing was carried out at a shear rate of 5000r / min, and the shearing time was 5min to obtain an oil-in-water emulsion; 0.83g of dibutyltin dilaurate was added dropwise to the oil-in-water emulsion solution, and reacted at 80°C for 4 hours to obtain the environment-friendly road microcapsule turbid solution; centrifuge the microcapsule turbid solution at 10,000r / min for 3min, take the upper fl...

Embodiment 2

[0041] An environment-friendly microcapsule for road use, the proportions of various substances are as follows, PVA: waste oil: IPDI: deionized water = 300: 150: 75: 450, and the amount of DBTDL added is 10% of the mass of IPDI. refer to figure 1 , its preparation method comprises the following steps:

[0042] Get 33.3g of 1788 type liquid PVA, drop it into 50g of deionized water, prepare emulsifier solution; mix 16.7g waste oil with 8.3g isophorone diisocyanate, prepare activated capsule core solution; mix emulsifier solution with The activated capsule core solution was mixed, and high-speed shearing was carried out at a shear rate of 4000r / min, and the shearing time was 8min to obtain an oil-in-water emulsion; 0.83g of dibutyltin dilaurate was added dropwise to the oil-in-water emulsion solution, and reacted at 80°C for 4 hours to obtain the environment-friendly road microcapsule turbid solution; centrifuge the microcapsule turbid solution at 10,000r / min for 3min, take the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com