Air-drying unsaturated polyester resin for easy-polishing gel coat, and preparation method thereof

A polyester resin and air-drying technology, which is applied in the field of air-drying unsaturated polyester resin for easy-grinding gel coats and its preparation, can solve problems such as adhesion, toughness and other performance adjustment difficulties, and achieve low porosity, Good adhesion, good air-drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

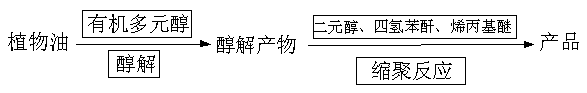

[0027] Such as figure 1 It is a schematic diagram of the synthesis process of the present invention, a method for preparing an air-drying unsaturated polyester resin for an easy-to-polish gel coat, which comprises the following steps:

[0028] A. Transesterification reaction:

[0029] The organic polyols and renewable vegetable oils are transesterified under certain reaction conditions, and the catalyst is one of lithium hydroxide, calcium hydroxide, potassium hydroxide, sodium hydroxide, sodium carbonate, sodium bicarbonate or lead oxide or various;

[0030] B. Polycondensation reaction:

[0031] The alcoholyzate prepared in step A is reacted with small molecule diols or dibasic acids, tetrahydrophthalic anhydride, and allyl ether. The head temperature is 95~105°C, the reaction temperature is 170~180°C, and resin / styrene is used =2 / 1 Prepare the sample, control the target value with a bubble tube viscosity or a cone-plate viscometer, the reaction end point is P~Q, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com