Block-hole-type graphite heat exchanger with forcedly deflecting and sealing characteristic

A technology of graphite heat exchanger and graphite heat exchange block, which is applied to the sealing of engines, heat exchange equipment, lighting and heating equipment, etc., which can solve the problem of unsatisfactory cooling effect, inability to reflux the cooling medium, and unavoidable cross-flow phenomena, etc. problems, to achieve the effect of improving equipment utilization, ensuring heat exchange effect, and remarkable energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

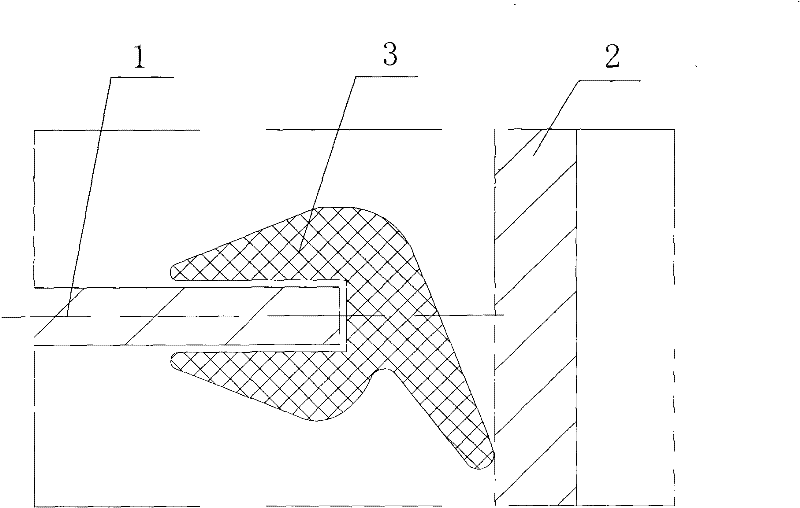

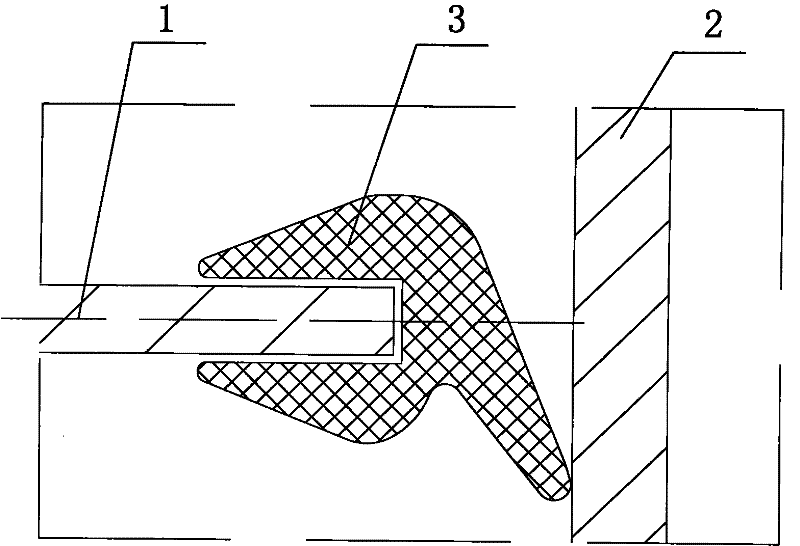

[0012] The accompanying drawing discloses a non-restrictive structural schematic diagram of a preferred embodiment involved in the present invention, and the technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0013] Such as figure 1 As shown, the forced baffle sealed block-hole graphite heat exchanger of the present invention includes a heat exchanger cylinder 2 and a heat exchanger assembly placed in the heat exchanger cylinder 2, and the heat exchanger The assembly is composed of stacked graphite heat exchange blocks. At the same time, each graphite heat exchange block is equipped with a baffle 1 respectively, and the baffle 1 and the inner wall of the heat exchanger cylinder 2 are sealed by a forced baffle seal 3 , the forced baffle seal 3 is made of fluorine rubber. One end of the baffle 1 is fixedly connected to the graphite heat exchange block, and the other end is suspended. One end of the forc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com