Direct-current motor based on specific electric brush installation angle

An installation angle, DC motor technology, applied in electromechanical devices, DC commutators, electrical components, etc., can solve the problem of poor contact between brush blades and commutators, wear of brush blades and commutator, and brush blades Large installation angle and other problems can reduce the probability of bursting, eliminate the accumulation of wear debris, and improve the effect of arc resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

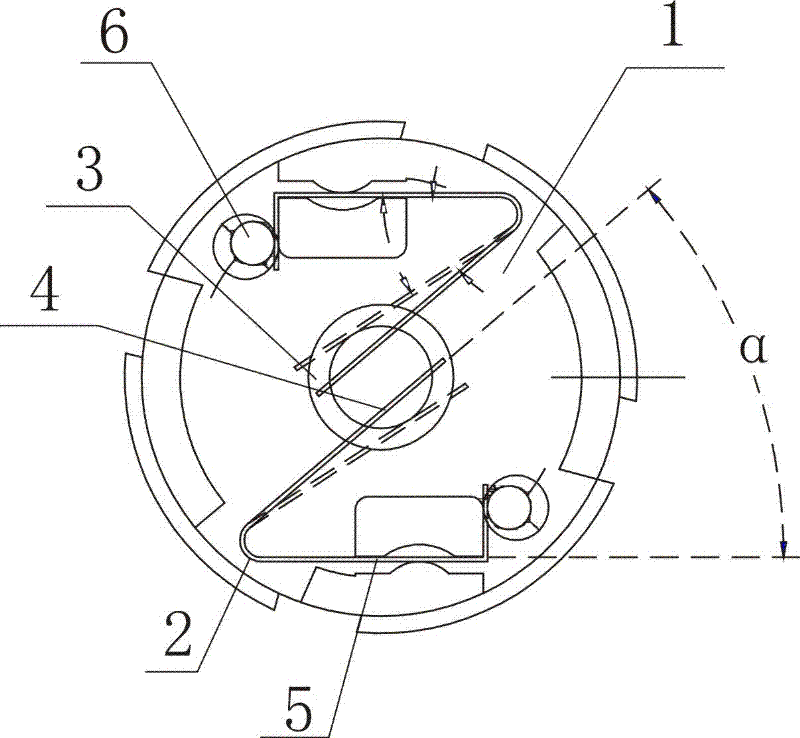

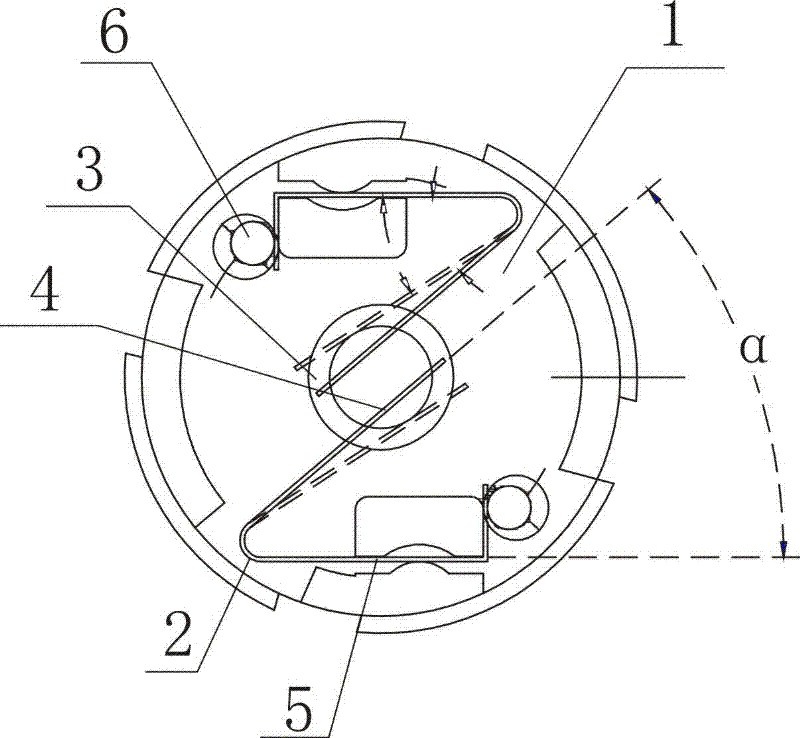

[0017] A DC motor based on a specific brush installation angle includes a motor 1 stator part and a rotor part, the motor 1 stator part is provided with a brush device 2, the motor 1 rotor part is provided with a reversing device 3, and the brush head 4 of the brush device 2 is connected to the Sliding contact of reversing device 3;

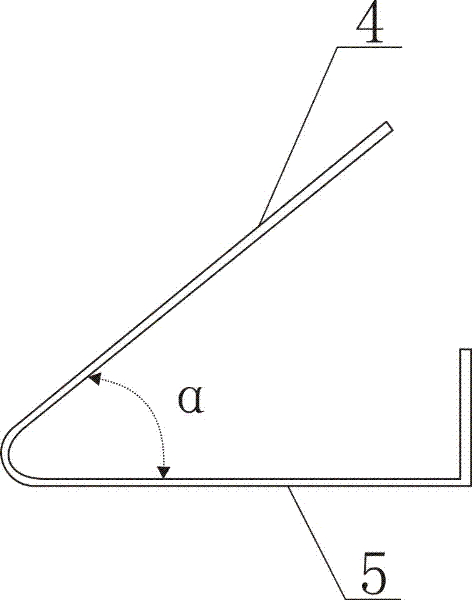

[0018] The included angle α between the brush head 4 and the brush handle 5 is 38°.

[0019] The welding spot 6 between the brush handle 5 and the lead wire of the motor 1 is formed by automatic welding.

[0020] The commutation piece and the brush head 4 of the reversing device 3 are plated with rare earth materials.

[0021] Implementation steps:

[0022] ①. The brush head 4 and the brush handle 5 of the brush device 2 are formed by bending an elastic metal sheet in advance, such as figure 2 As shown, the angle α between the brush head 4 and the handle 5 formed after bending is 38°. The brush device 2 is embedded in the motor 1 and has a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com