Filter device

A filter device and closing device technology, which is applied in the direction of filtration separation, membrane filter, separation device, etc., can solve the problem that the filter device cannot complete the filtration function, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

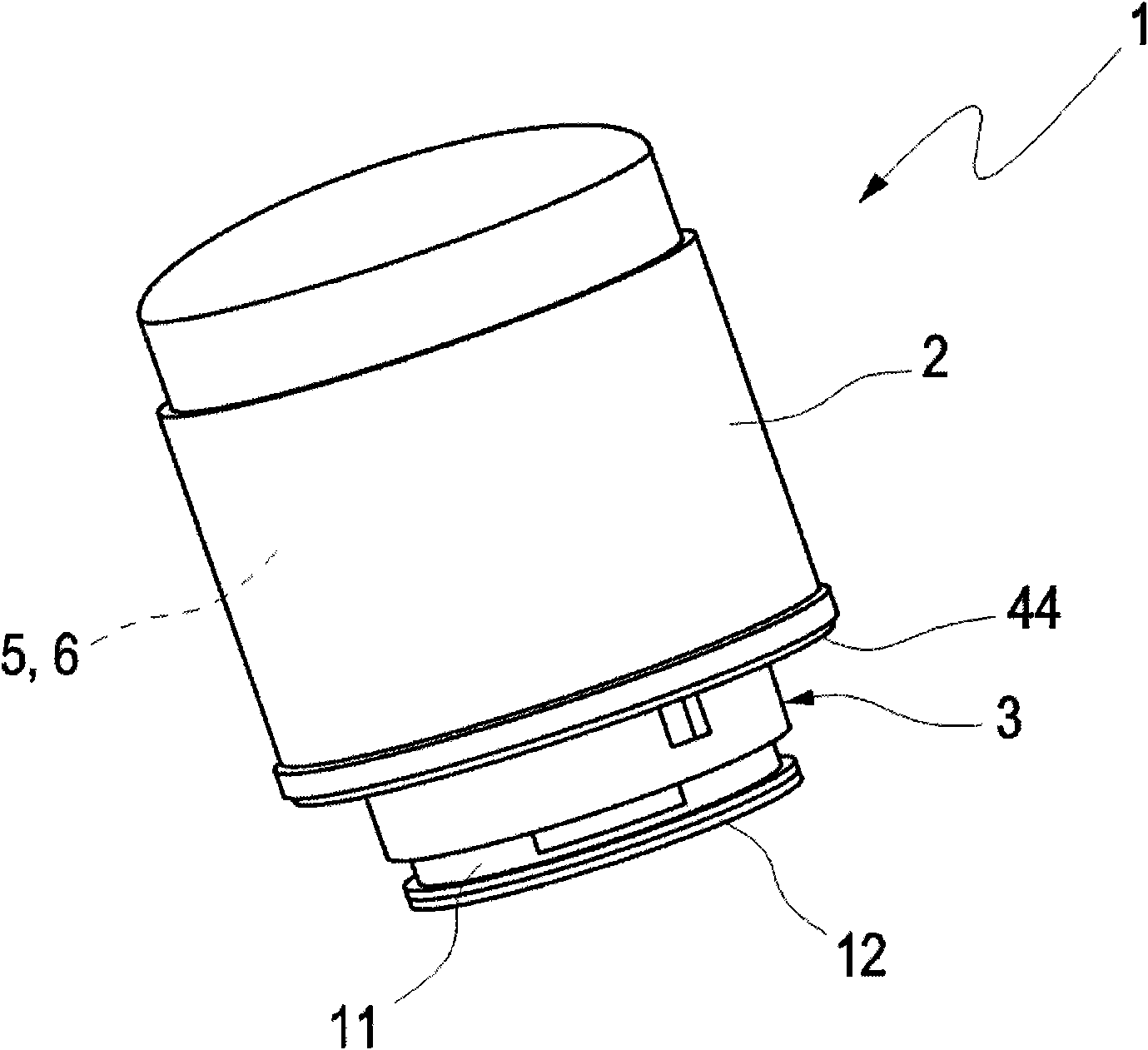

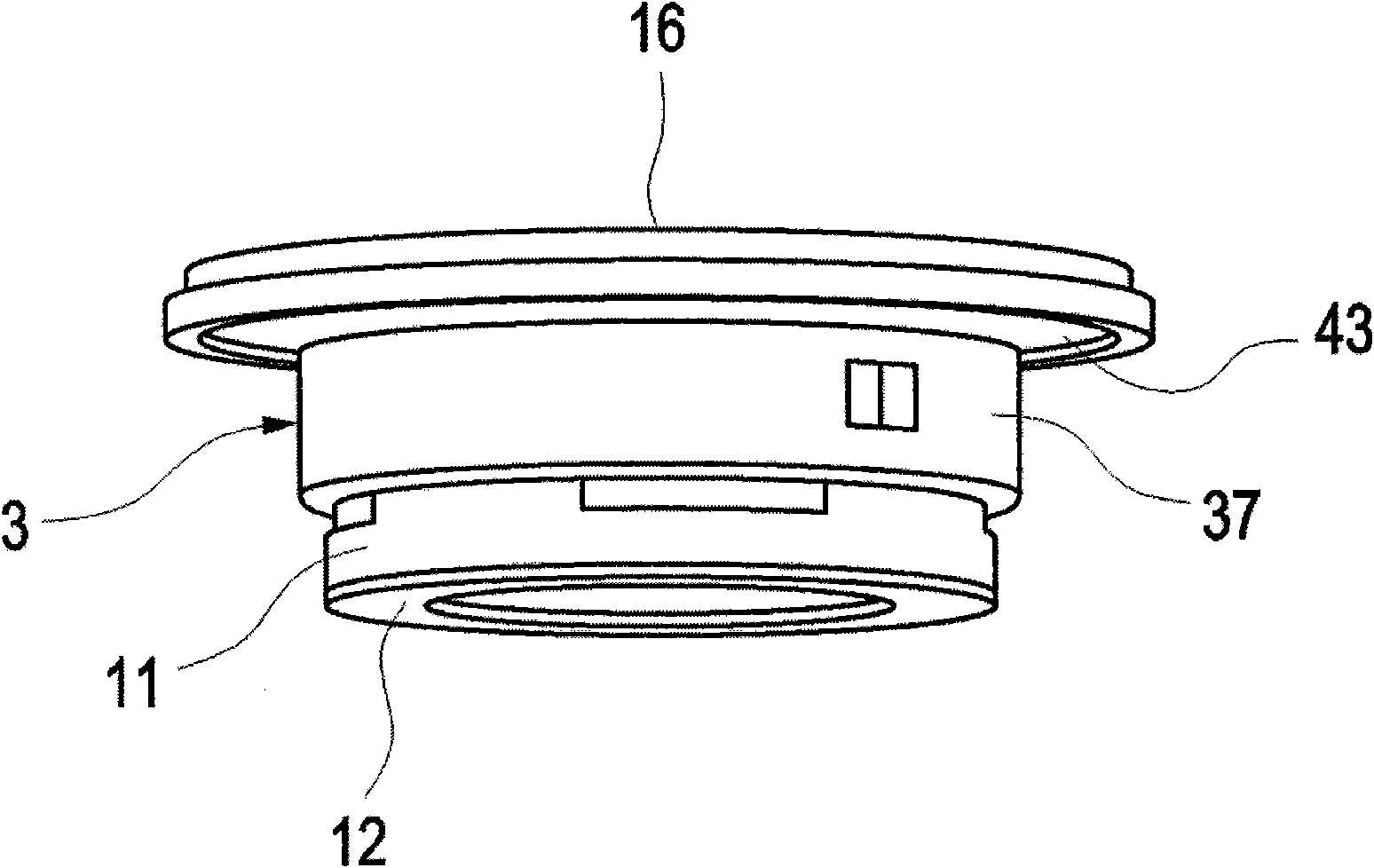

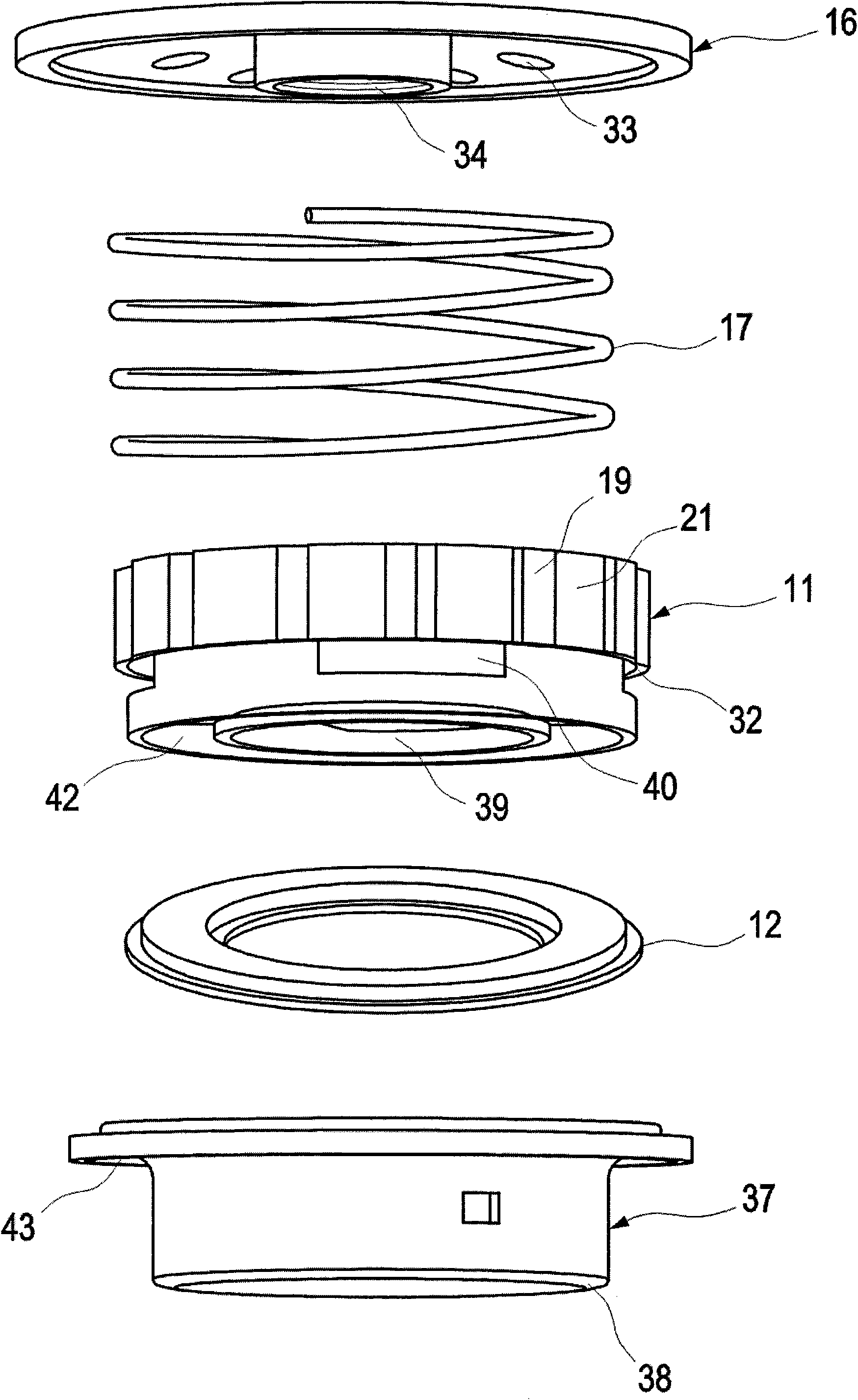

[0025] exist figure 1 , the filter device 1 can be seen from the outside. It comprises a filter housing cover 2 ; the latter forms inside it a receiving chamber 5 in which an annular filter element 6 is arranged such that it separates the untreated side from the clean side. The internal structure is a conventional replacement filter, which is suitable for filtering oil. The middle block 3 is placed on the side of the filter device 1 facing the housing 4 . The housing 4 onto which the filter device 1 is screwed firmly can be, for example, an engine cylinder housing or a cylinder housing. For reasons of simplification, it will only be referred to as housing 4 . The housing 4 is configured such that it includes a threaded dome 15, a ramp 22 adjacent to the dome 15, and an inlet channel 7, an outlet channel 8 and an outlet channel 9 (see Figure 7 with 8 ).

[0026] exist figure 2 In the illustration, the middle block 3 is shown, which is tightly connected with the filter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com