Wheel suspension for the rear wheels of motor vehicles

A technology of motor vehicle and suspension, which is applied in the direction of suspension, elastic suspension, steering mechanism, etc., and can solve the problems of cost, complexity, increased consumption, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

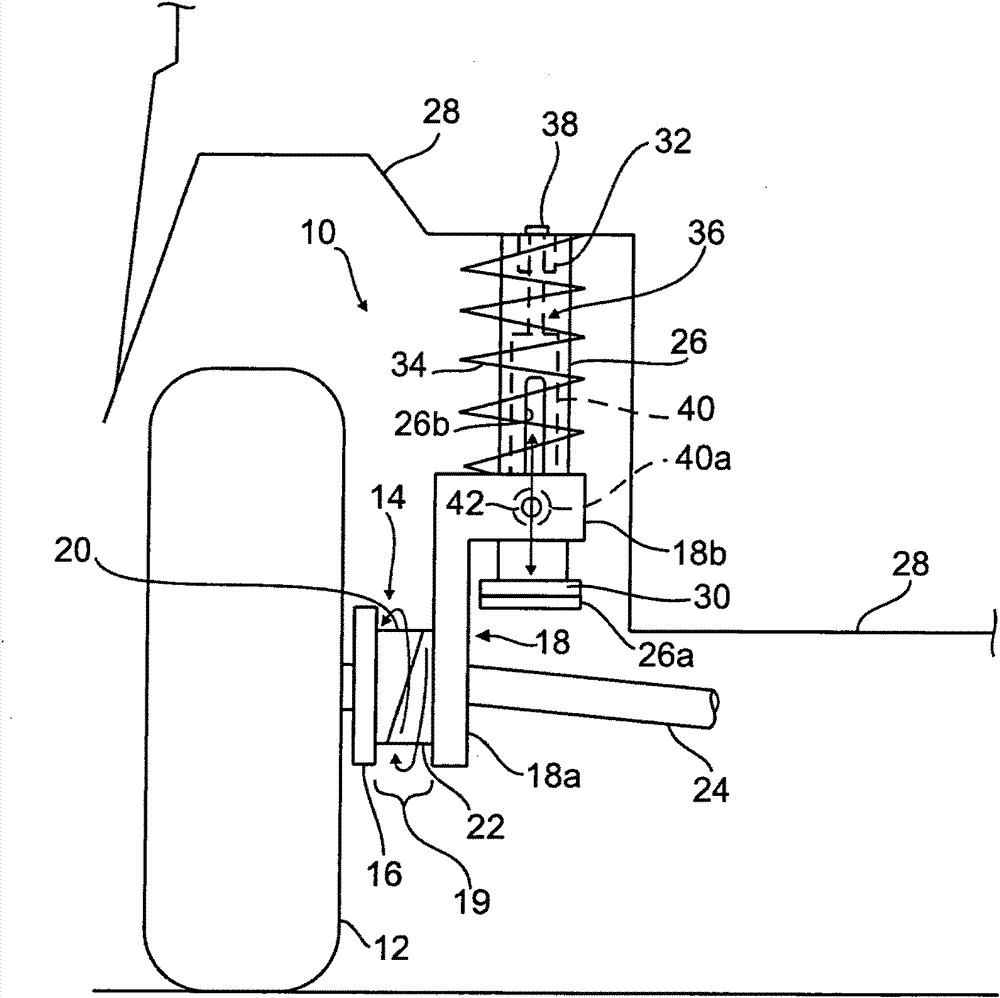

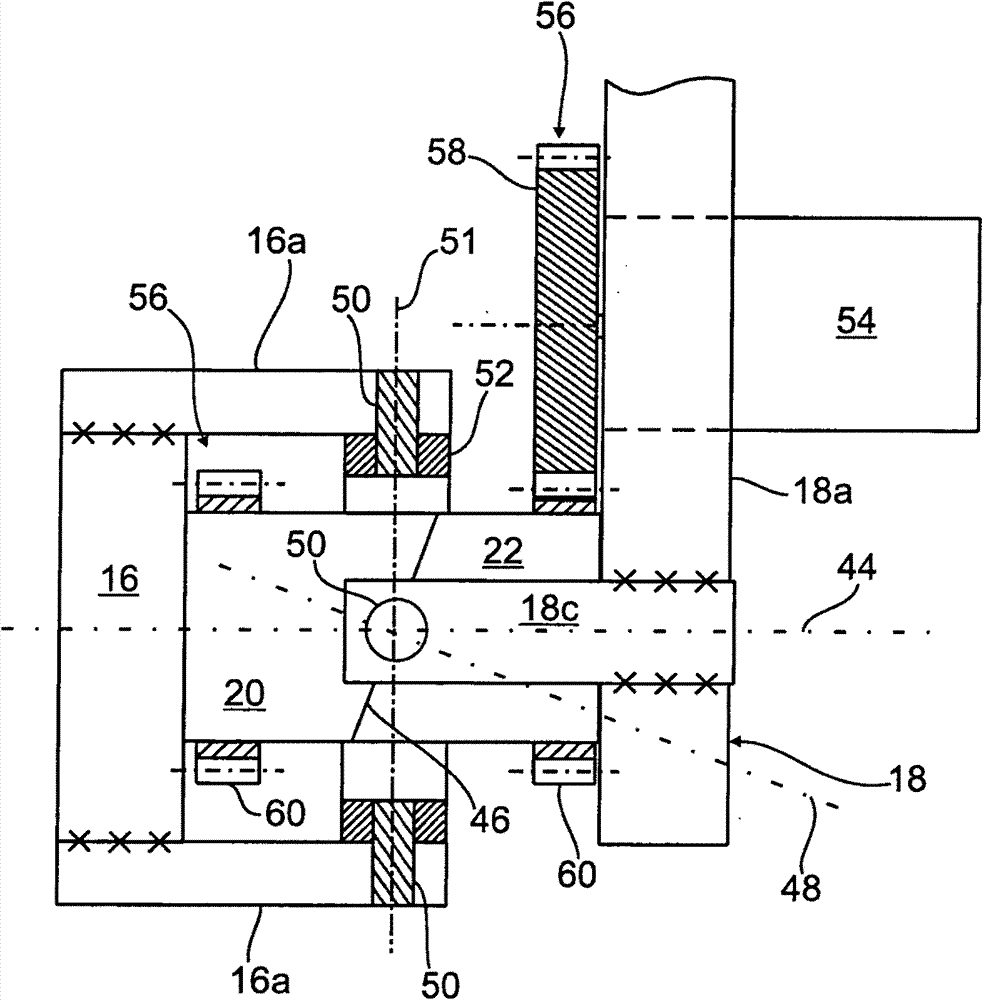

[0021] figure 1 The wheel suspension structure of a motor vehicle is marked with "10", the rear wheel 12 of which is rotatably supported on the wheel hub bracket 14.

[0022] The multi-piece hub bracket 14 is composed of a carrier part 16 for receiving the wheel 12, a guide part 18 on the suspension side and an actuator 19 connected between the two. The actuator 19 has two rotating parts that can rotate relative to each other. Or adjust cylinders 20,22.

[0023] The guide element 18 has an approximately vertically extending section 18a through which a cardan shaft 24 (only partly shown) of the drive wheel 12 extends.

[0024] A sleeve-shaped section 18b protrudes approximately horizontally from the vertical section 18a of the guide element 18 toward the longitudinal center plane of the vehicle, and is guided displaceably on a tubular cylinder 26 as a linear guide.

[0025] The column 26 is fastened to the monocoque body 28 of the motor vehicle and has at its lower end an ann...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com