Optical level composite pressure-sensitive adhesive and an apparatus therewith

A pressure-sensitive adhesive, optical-grade technology, applied in the field of pressure-sensitive adhesive to achieve the effect of improving air bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

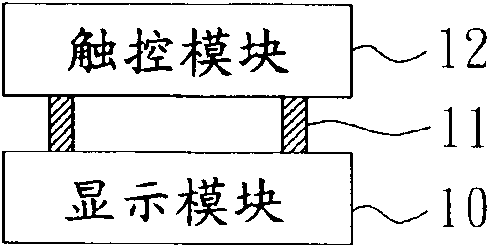

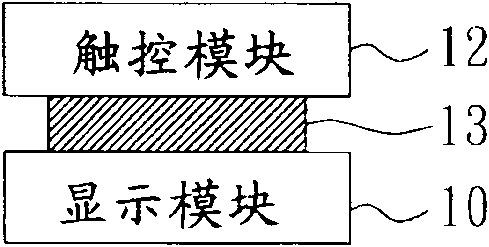

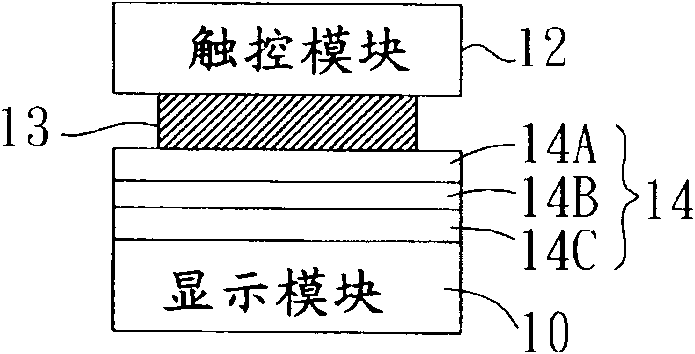

[0081] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the optical-grade composite pressure-sensitive adhesive proposed according to the present invention and the device with optical-grade composite pressure-sensitive adhesive are described below in conjunction with the accompanying drawings and preferred embodiments. Its specific implementation, structure, feature and effect thereof are described in detail as follows.

[0082] Figure 2A The side view of the stacked diagram shows an optical level composite pressure-sensitive adhesive (optical level composite pressure-sensitive adhesive, referred to as composite pressure-sensitive adhesive) 20 according to an embodiment of the present invention, and its two sides are attached to the light-transmitting first adhesive layer 21 and the first adhesive layer 21 respectively. The light-transmitting second bonding layer 22 . In this specification,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com