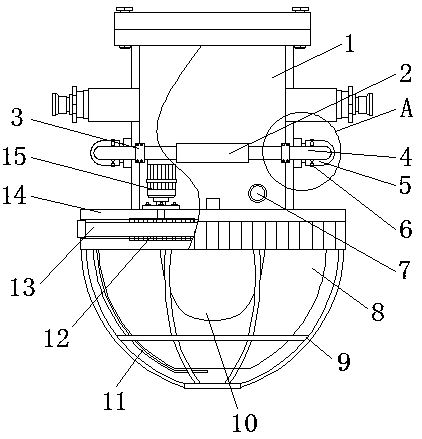

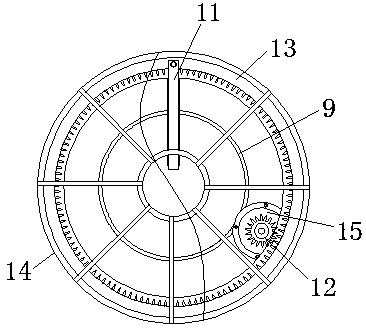

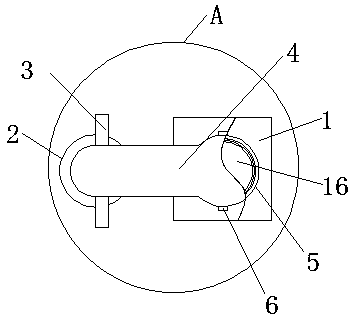

A mine explosion-proof searchlight

An explosion-proof searchlight technology, which is applied in the field of searchlights, can solve the problems of inconvenient searchlight angles and accumulation of dust, and achieve the effects of being easy to hold, increasing the irradiation range, and improving the field of vision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A method for preparing a corrosion-resistant and heat-dissipating material with a micro-arc oxidation / graphene composite coating, comprising the following steps:

[0031] Step 1. Select Mg-Zn-Ca-Sm-Be alloy as the substrate, polish the surface with 600, 800, 1000 and 1200# sandpaper in turn, and then use acetone and alcohol to ultrasonically clean it for 15 minutes;

[0032] Step 2, with NaAlO 2 :2g / L,NaOH:3g / L,nano-Al 2 o 3 :lg / L and sodium dodecylbenzenesulfonate SDBS:lg / L ratio

[0033] Example mixing, mechanical stirring, prepared nano-Al 2 o 3 Modified micro-arc oxidation electrolyte;

[0034] Step 3. Use the stainless steel plate of the electrolytic cell as the cathode, and the Mg-Zn-Ca-Sm-Be alloy as the anode, use the micro-arc oxidation electrolyte prepared in the above steps, and then use the pulse power supply as the power supply, and apply The voltage of 300V, and under the condition of voltage of 300V, temperature lower than 50℃ and stirring, the oxid...

Embodiment 2

[0042] Step 2, with NaAlO 2 :1g / L,NaOH:3g / L,nano-Al 2 o 3 :lg / L and sodium dodecylbenzenesulfonate SDBS:lg / L ratio

[0043] Example mixing, mechanical stirring, prepared nano-Al 2 o 3 Modified micro-arc oxidation electrolyte; other preparations are the same as in Example 1.

Embodiment 3

[0045] Step 2, with NaAlO 2 :2g / L,NaOH:3g / L,nano-Al 2 o 3 :lg / L and sodium dodecylbenzenesulfonate SDBS:lg / L ratio

[0046] Example mixing, mechanical stirring, prepared nano-Al 2 o 3 Modified micro-arc oxidation electrolyte; other preparations are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com