Light-emitting diode packaging structure

A technology of light-emitting diodes and packaging structures, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., and can solve the problem that the position of the welding pad cannot be adjusted.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

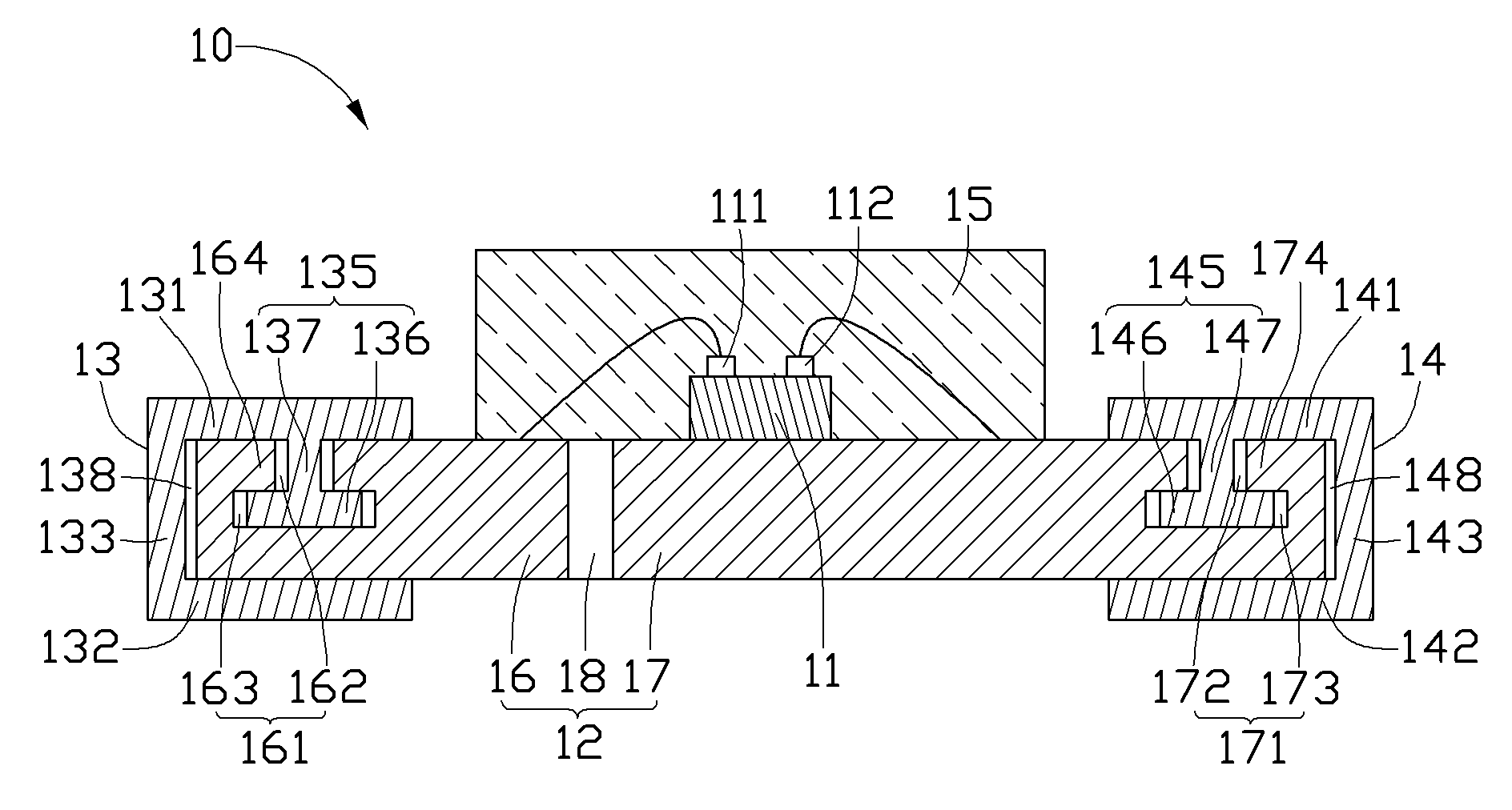

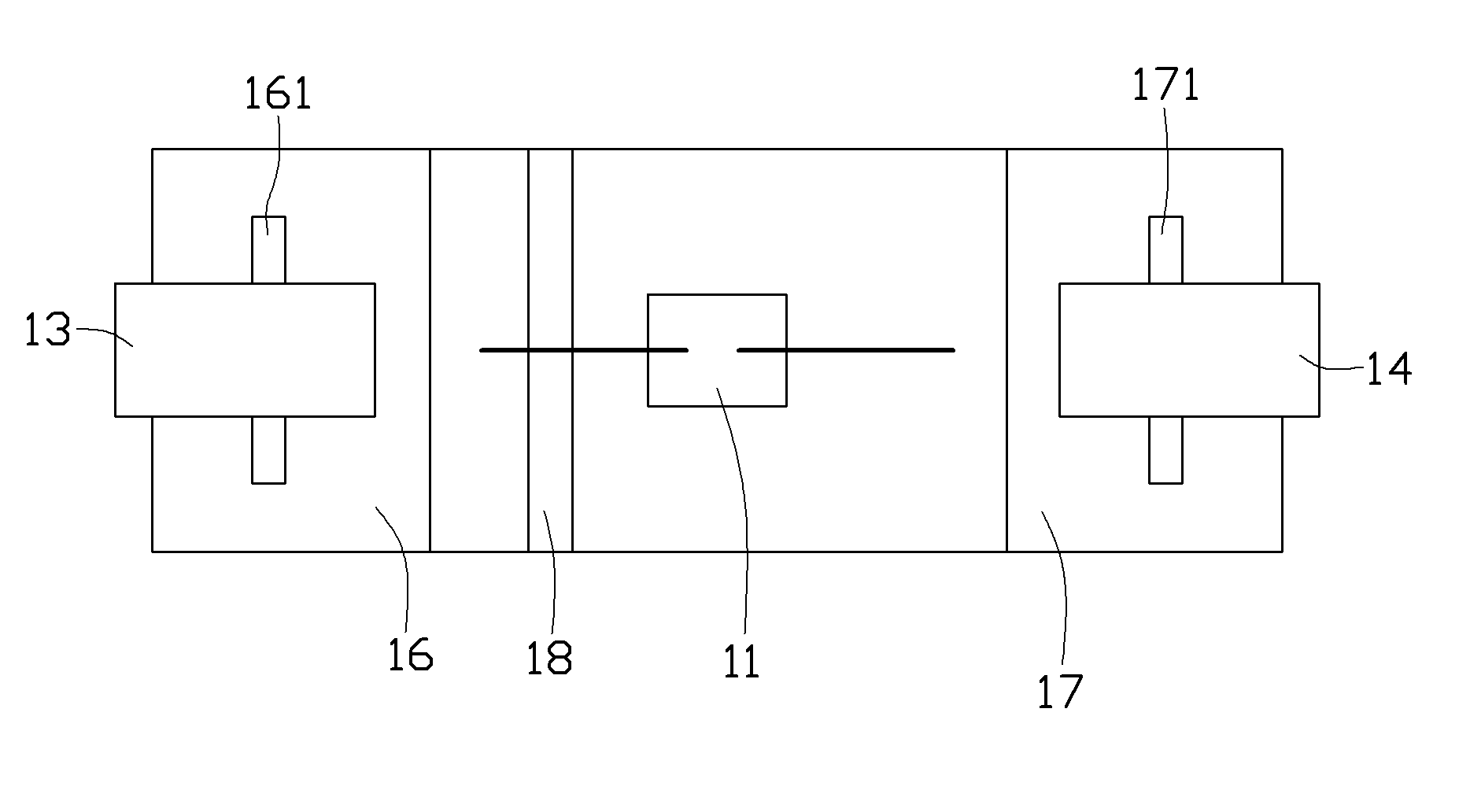

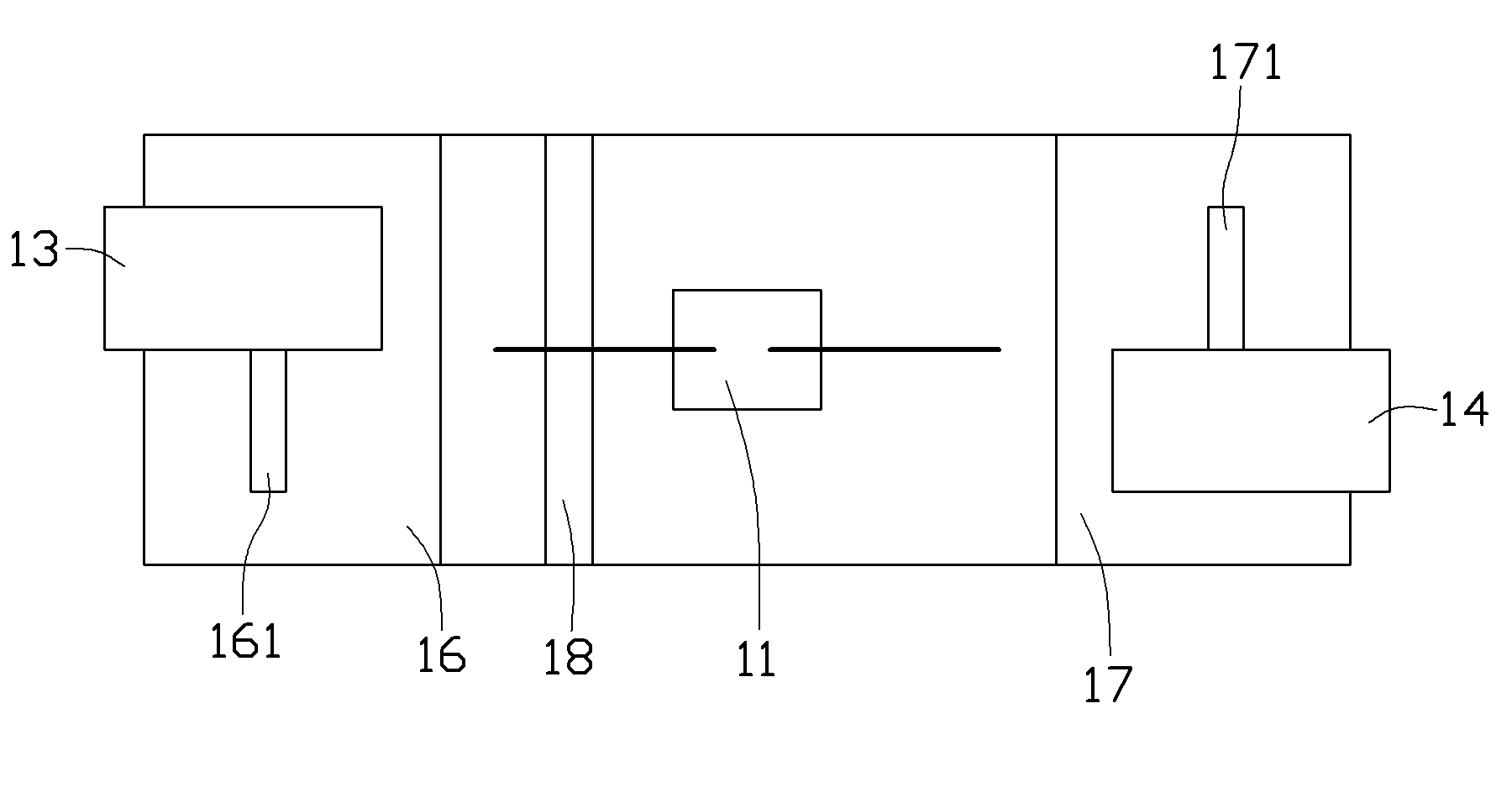

[0044] see figure 1 and figure 2 A light emitting diode packaging structure 10 provided in an embodiment of the present invention includes a light emitting diode die 11 , a conductive substrate 12 , a first pad 13 , a second pad 14 and a package body 15 .

[0045] The conductive substrate 12 includes a first conductive region 16 and a second conductive region 17 which are insulated from each other, and the first conductive region 16 and the second conductive region 17 are connected by an insulating material 18 . The first conductive area 16 defines a first sliding slot 161 , the second conductive area 17 defines a second sliding slot 171 , and the first sliding slot 161 and the second sliding slot 171 are parallel to each other. The first chute 161 is narrow on the outside and wide on the inside. The first chute 161 includes a first horizontal section 163 and a first vertical section 162 . The intersection of the straight segments 162 forms a first shoulder 164 . The secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com