Laser welding method and system for end faces of copper and copper alloy plates with different thicknesses

A laser welding and alloy plate technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of reduced welding performance, lack of copper and its alloy end face welding methods, unsatisfactory, etc., and achieve a smooth transition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

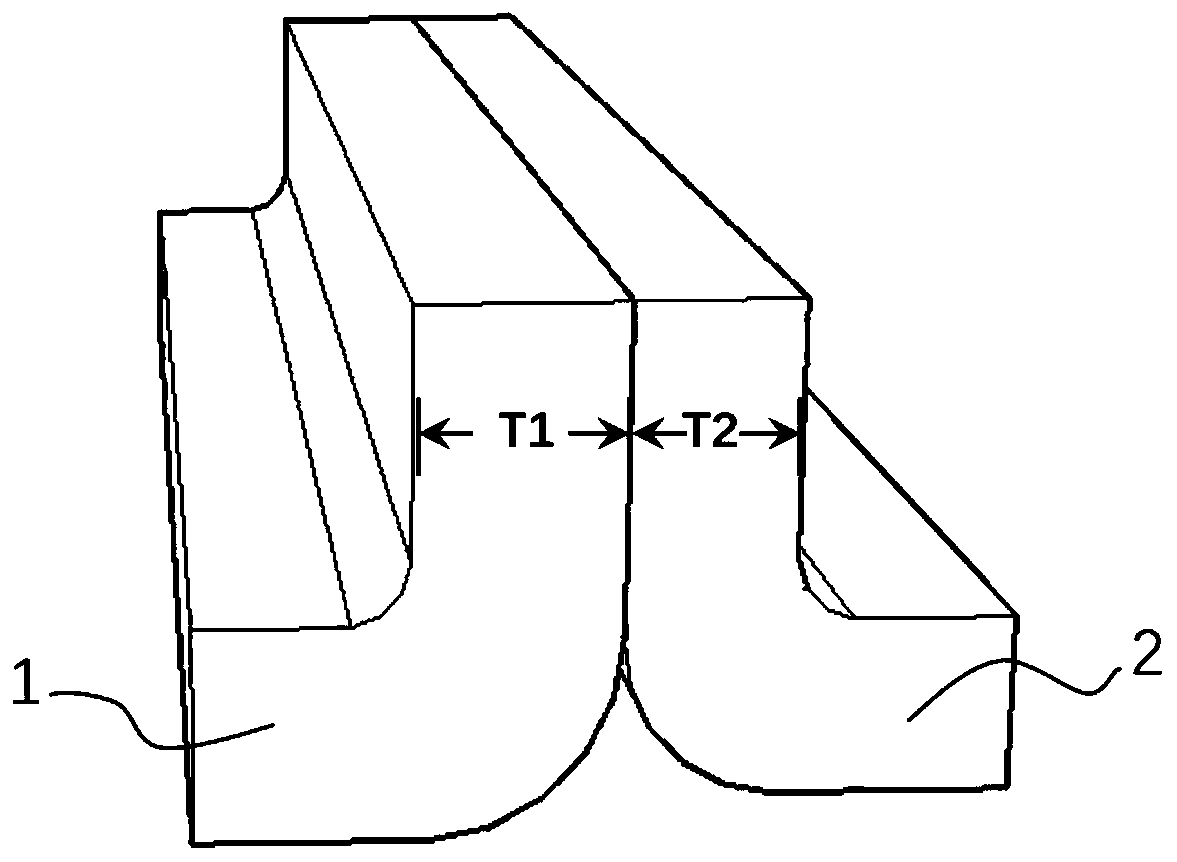

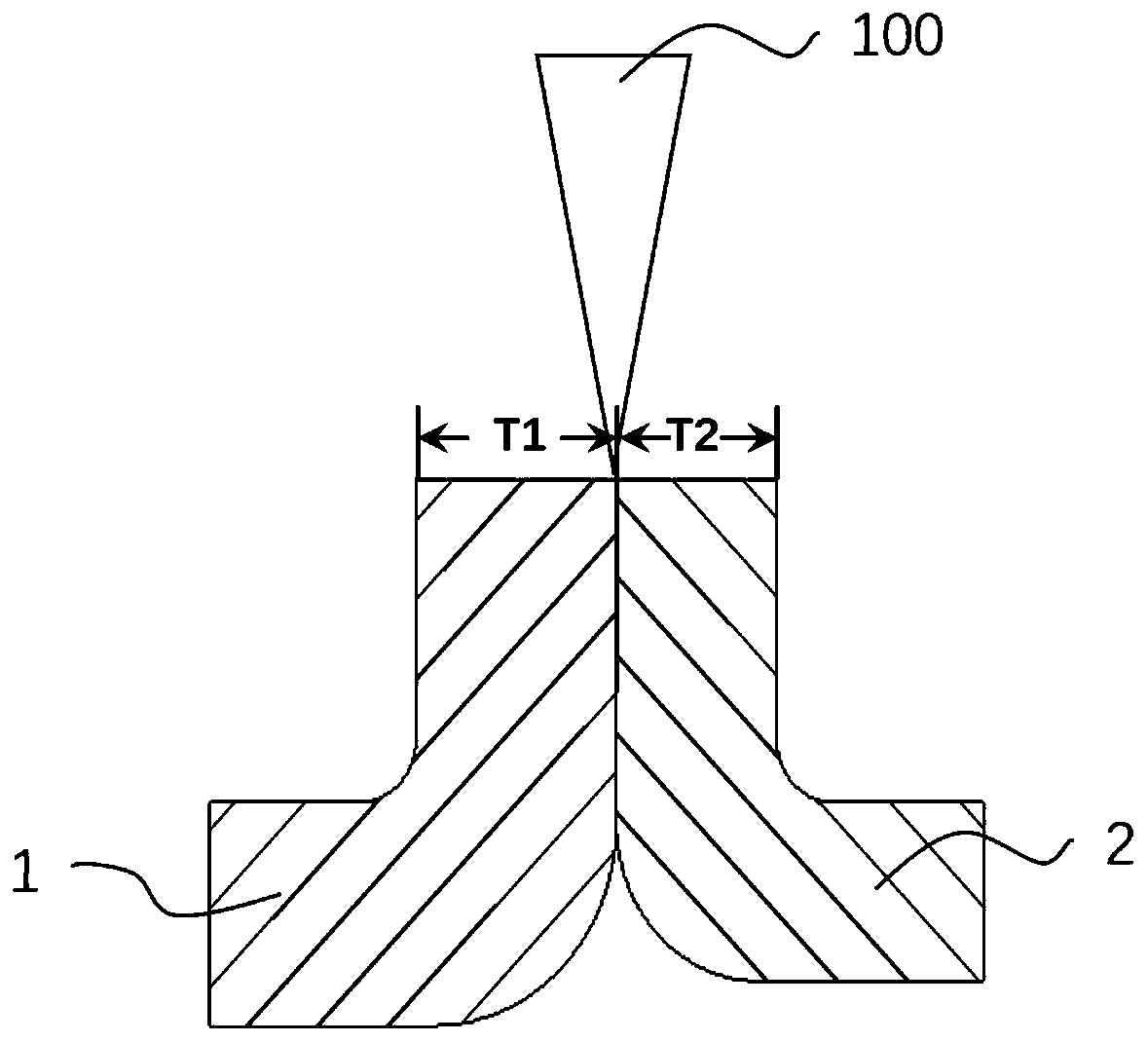

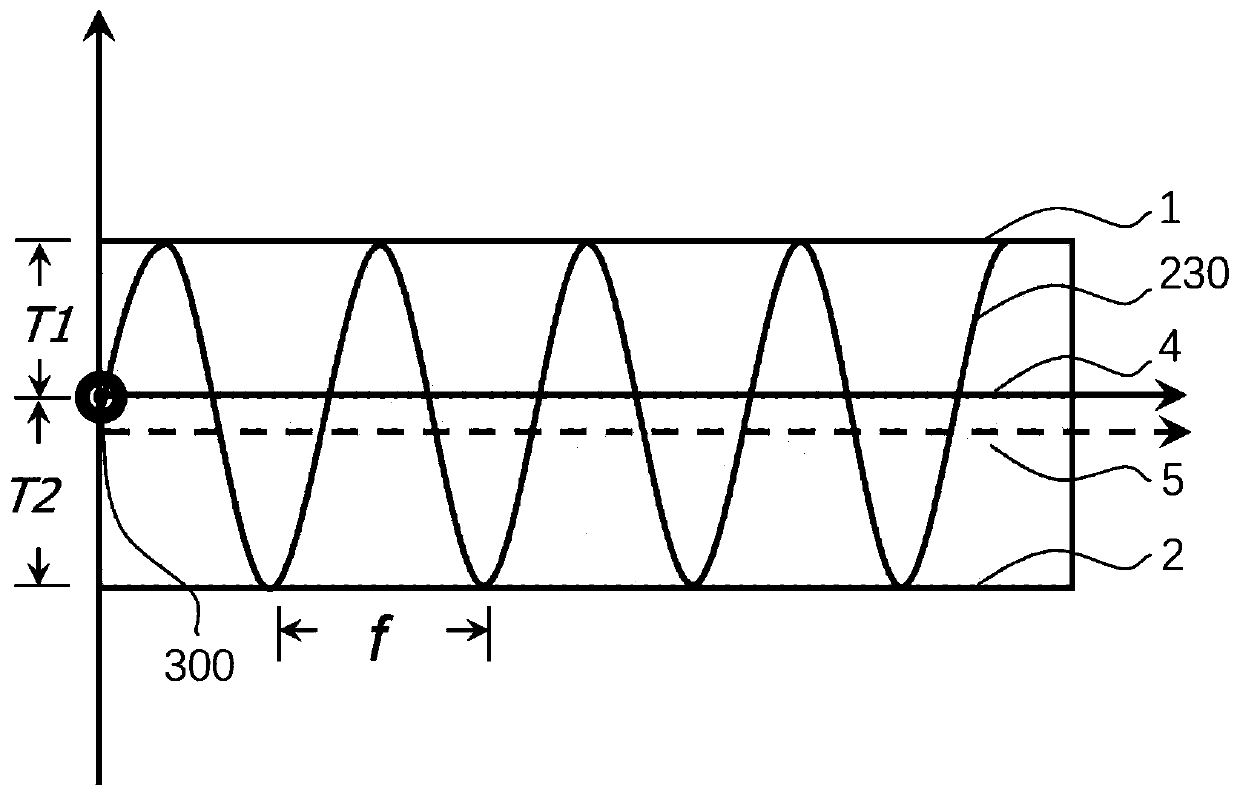

[0068] The laser welding method for the end faces of copper and its alloy plates with different thicknesses provided in this embodiment is specifically:

[0069] Red copper with a thickness of 3 mm and a thickness of 5 mm is used as the welding test piece, the welding position is the end face position, the welding depth is 4 mm, and the length of the structural part is 100 mm. According to the requirements of the welding depth, the laser power is 6000W, the outer ring laser beam 302 is set to 1200W, and the center laser beam 301 is set to 100% to 6000W; according to the plate thickness, the laser swing amplitude is set to 4mm, and the swing frequency is 150Hz. Before welding, according to the thickness of the first plate 1 and the second plate 2, the movement route of the laser head is set, parallel to the welding direction 4, and the vertical direction of the weld 3 is negatively deviated by 1mm, and the laser beam movement trajectory 230 is according to Y=4sin(300πt +0.25) m...

Embodiment 2

[0073] Red copper with a thickness of 4mm and 8mm is used as the welding test piece, the welding position is the end face position, the welding depth is 5mm, and the length of the structural part is 100mm. Select laser power 6500W according to welding depth requirements, outer ring laser beam 302 is set to 1200W, center laser beam 301 is set to 100% to 6000W; according to plate thickness, laser swing amplitude is set to 6mm, and swing frequency is 200Hz. Before welding, set according to copper plate thickness The laser head movement route is parallel to the welding direction 4, and the vertical direction of the weld 3 is negatively deviated by 2mm. The laser beam movement trajectory 230 moves according to Y=6sin(400πt+0.34). During the welding process, the laser beam power follows the laser beam movement trajectory. The multi-line center laser power change curve 210 and the outer ring laser power change curve 220 are adjusted to ensure that the center laser beam 301 matches the...

Embodiment 3

[0075] This embodiment is basically the same as Embodiment 1, except that brass different from Embodiment 1 is used as the welding test piece. The laser power is 5000W, and the laser swing frequency is 200Hz.

[0076]In summary, the laser welding method for the end faces of copper with different thicknesses and its alloy plates provided by the embodiment of the present invention aims at the welding problems that occur in the laser welding of the end faces of copper with different thicknesses and its alloy plates. Swing welding, and set the swing amplitude, swing frequency and laser beam power of the laser beam 300 respectively according to the thickness of the first plate 1 and the second plate 2 to be welded, and form the outer ring laser beam 302 through laser shaping of the laser beam 300 and the center laser beam 301, wherein the outer ring laser beam 302 plays the role of preheating the first plate 1 and the second plate 2, and the absorption rate of the copper and its al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com