Hammering tool

A technology of impact tools and installation tools, which is applied in the field of impact tools, can solve problems such as poor workability and damage, and achieve the effects of improving reliability, maintaining miniaturization, and excellent operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Embodiments of the present invention will be described below based on the drawings. In addition, in the form after form 2, the same code|symbol is attached|subjected to the structural part common to form 1, and the overlapping description is abbreviate|omitted.

[0045] [Method 1]

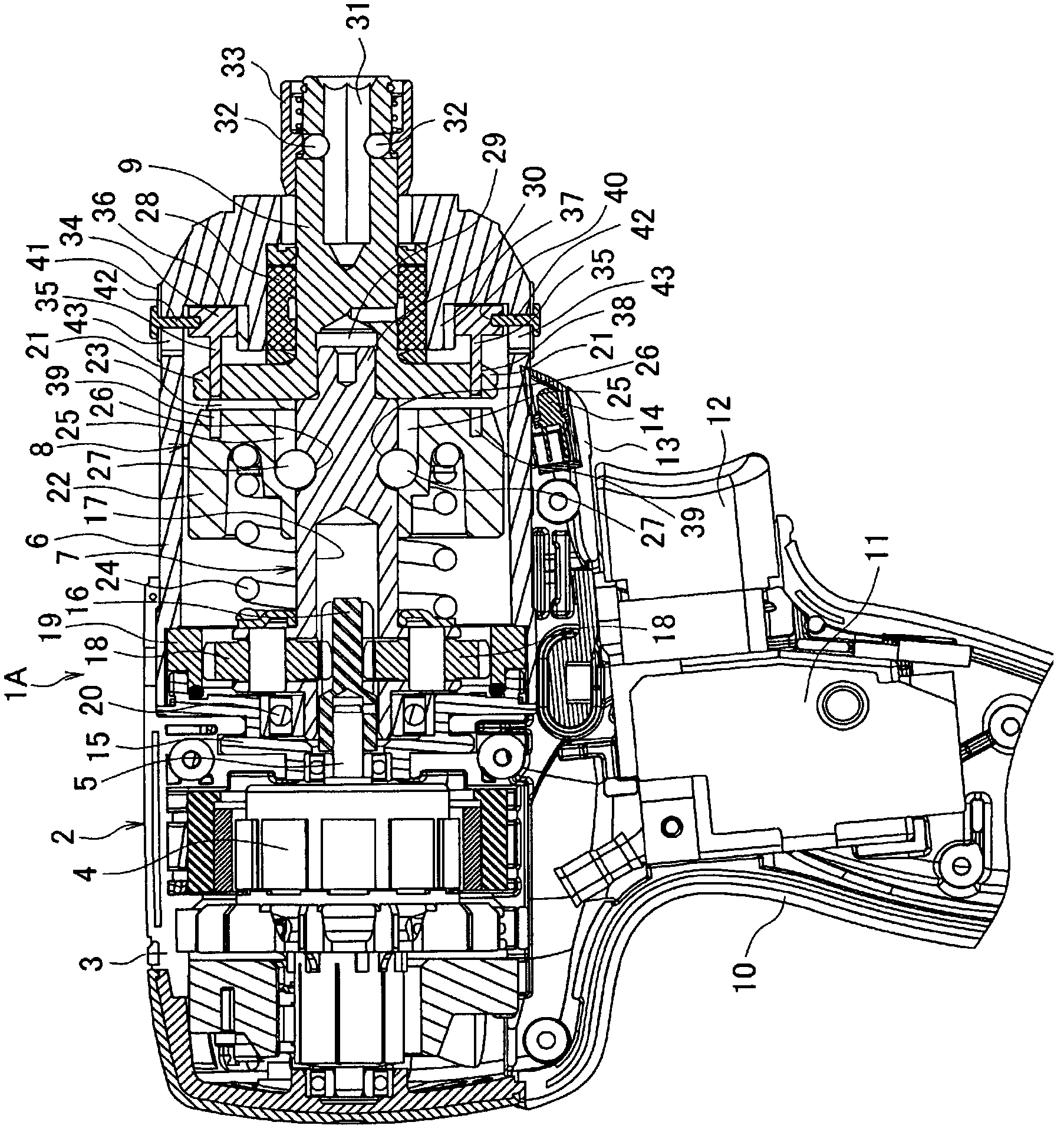

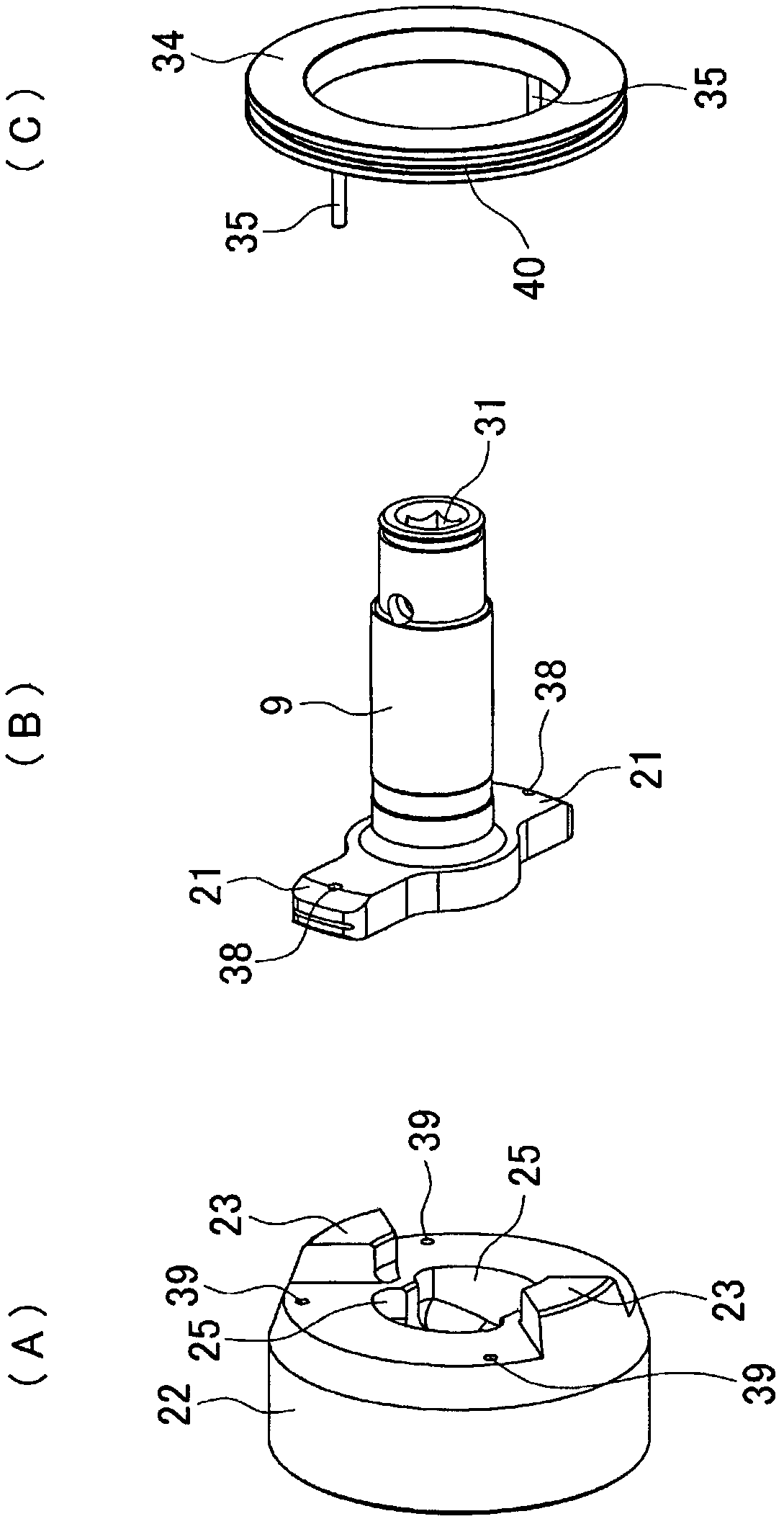

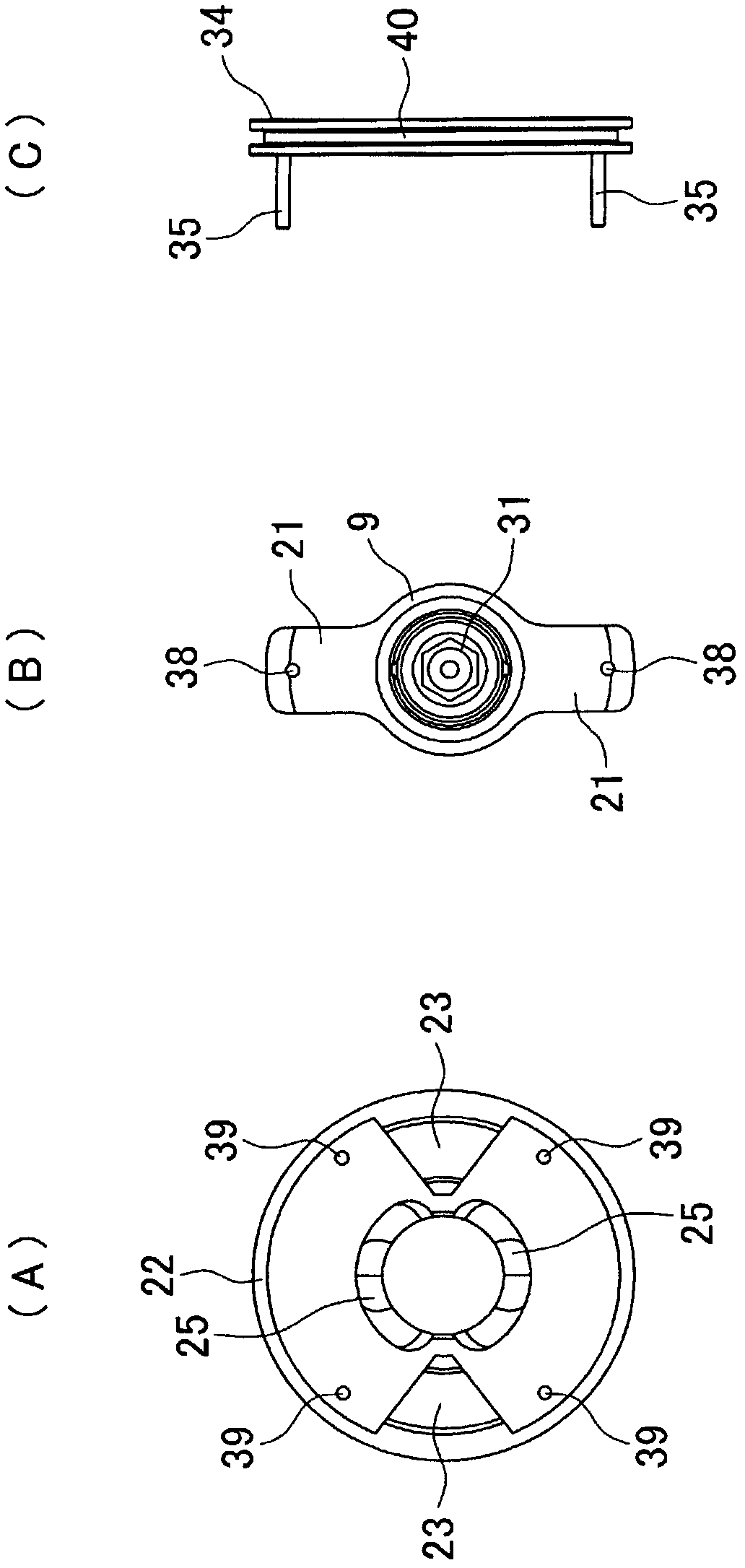

[0046] Such as figure 1 As shown, an impact screwdriver 1A as an example of an impact tool has: a main body case 2, which is formed by assembling left and right half cases 3, 3, and houses a motor 4; and a hammer case 6 with a bell-shaped cross section. , which is the front shell, assembled in front of the main body shell 2 ( figure 1 The right side in the middle), and accommodate the main shaft 7, the impact mechanism 8, and the anvil 9. A handle 10 is extended below the main body case 2 , and a switch 11 with a trigger 12 is housed in the upper portion of the handle 10 . A battery pack (not shown) serving as a power source is installed at the lower end of the handle 10 . Further, in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com