Film cutter

A film cutting and copolymer technology, used in thin material processing, packaging, metal processing, etc., can solve the problems of long time, adhesive strength, insufficient adhesive strength, etc., and achieve the effect of excellent melt viscosity and easy installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

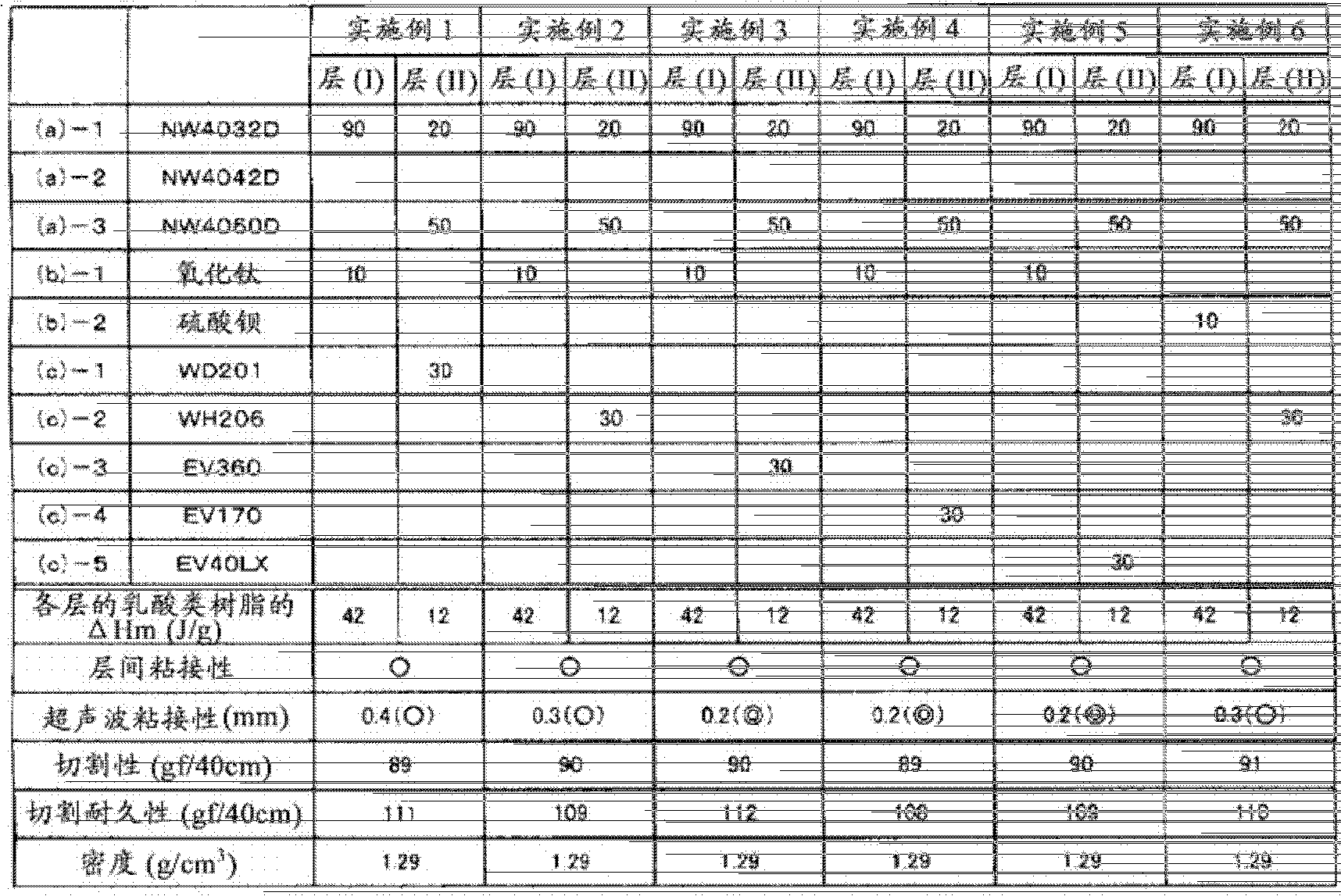

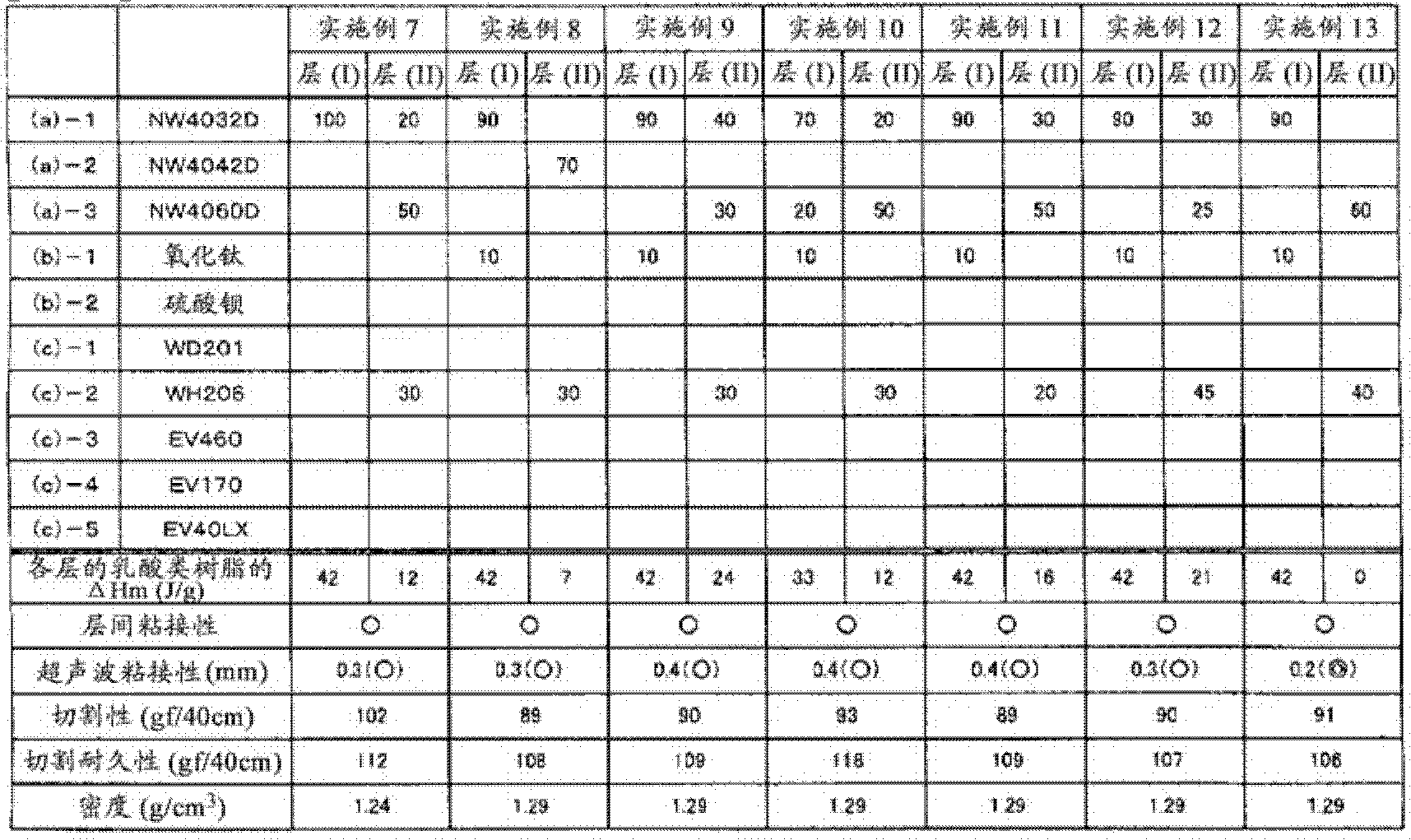

Embodiment 1

[0172] Mix (a)-1 and (b)-1 at a mixing mass ratio of 90:10, and use a φ40mm co-rotating twin-screw extruder at 210°C to extrude the layer from a 2-layer multi-manifold die lip (I), at the same time, mix (a)-1, (a)-3 and (c)-1 with the ratio of mixing mass ratio 20:50:30, and utilize φ 25mm co-rotating twin-screw extruder at 210 The layer (II) was extruded from the same die lip at 0°C to obtain a coextruded sheet. At this time, the extrusion amount of molten resin was adjusted so that the thickness ratio of layer (I) and layer (II) was 9:1.

[0173] Next, the coextruded sheet was quenched with a casting roll at about 55° C. to obtain an unstretched sheet.

[0174] Then, at a temperature of 75°C, the length direction is stretched 2.5 times in the longitudinal direction, and the width direction is stretched to 3.0 times at a temperature of 75°C with a tenter. Heat treatment was carried out at a temperature of 100°C to form a laminate.

[0175] Regarding the thickness of the la...

Embodiment 2

[0178] As the layer (II), a resin composition obtained by mixing (a)-1, (a)-3, and (c)-2 at a mixing mass ratio of 20:50:30 was used, and in addition, Production and various evaluations of the laminate were performed in the same manner as in Example 1. The results are shown in Table 1.

Embodiment 3

[0180] As the layer (II), a resin composition obtained by mixing (a)-1, (a)-3, and (c)-3 at a mixing mass ratio of 20:50:30 was used, and in addition, Production and various evaluations of the laminate were performed in the same manner as in Example 1. The results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com