Light assembly

A technology of lamp components and lighting components, which can be applied to vehicle parts, parts of lighting devices, semiconductor devices of light-emitting elements, etc., and can solve problems such as limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

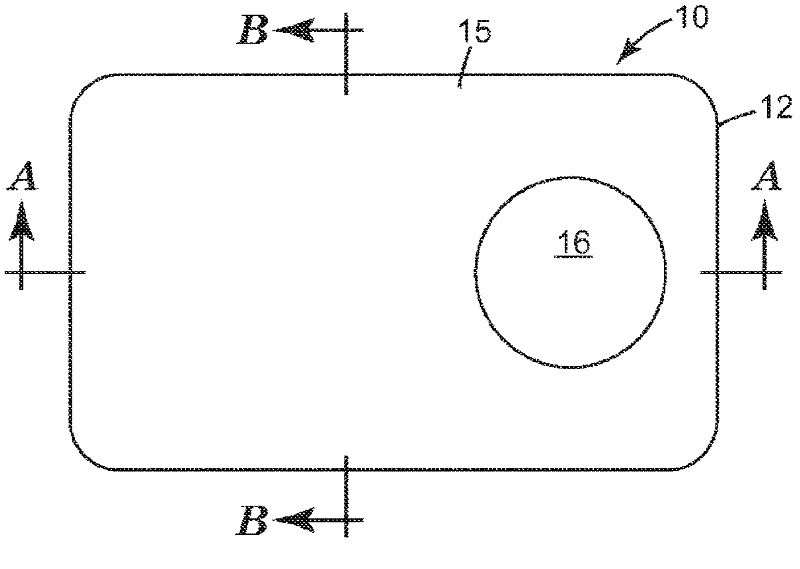

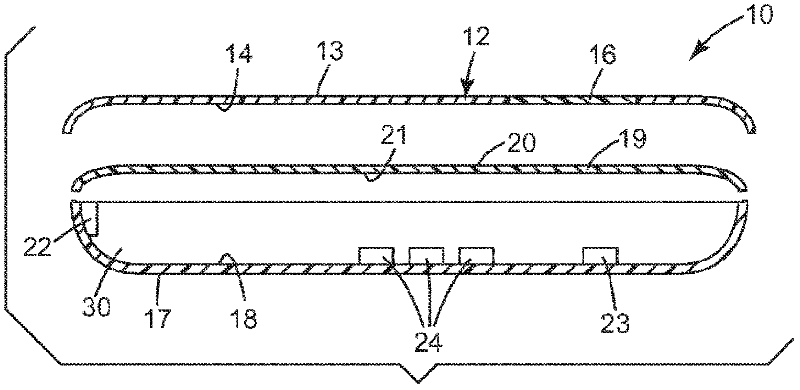

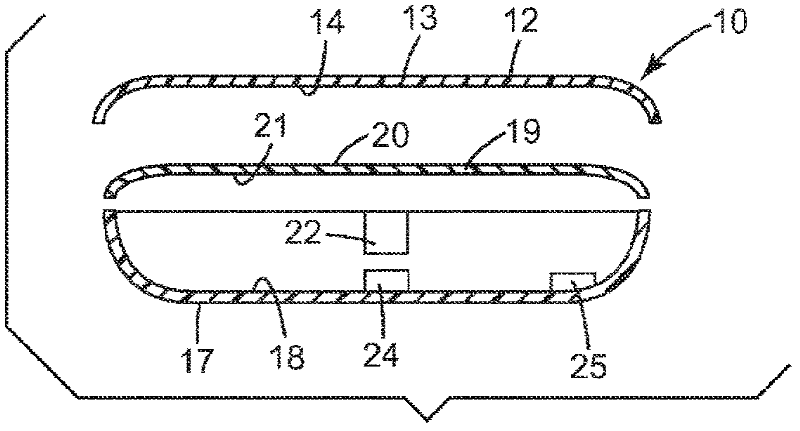

[0027] refer to figure 1 , Figure 1A with Figure 1B, shows an exemplary lamp assembly of the present invention. The automotive tail light assembly 10 has an (optionally curved) outer light housing 12 having substantially opposite first and second major surfaces 13 and 14, a first region 15 having a first color, such as red and a second region 16 of a second different color, such as clear or white. The automobile taillight assembly 10 also includes: a reflector 17 having an inner major surface 18; an inner lens 19 disposed between the outer lamp housing 12 and the reflector 17, wherein the inner lens 19 has substantially opposite first and second major surfaces 20, 21, and wherein at least one of the first or second major surfaces 20, 21 is transflective; and a first light source 22 emitting a first color (eg red) when energized. There is an optical cavity 30 between the inner lens major surface 21 and the reflector major surface 18 . The first light source 22 (e.g. red...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com