Overmoulded safety and waterproof photo voltaic connector

A technology of connectors and female connectors, which is applied in the direction of connection, parts of connection devices, assembly/disassembly of contacts, etc., and can solve the problems that connectors cannot be completely impervious to water and have low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

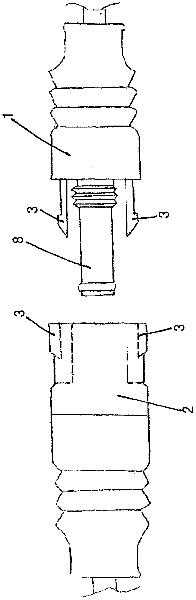

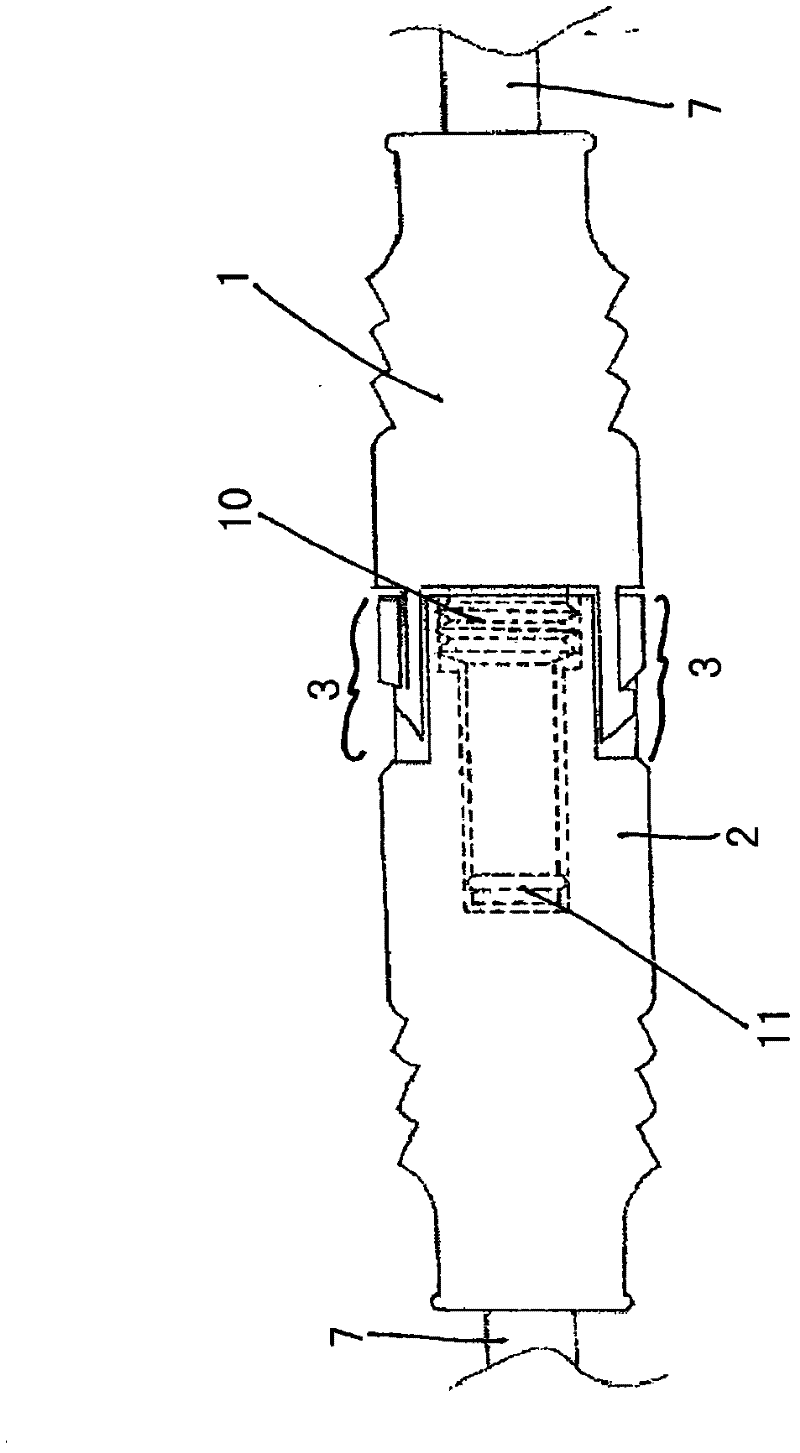

[0028] refer to figure 2 , a preferred schematic embodiment of a PV connector according to the invention is shown prior to assembly with a male connector 1 aligned on one side and a female connector 2 aligned on the other side, however Figure 1 shows State-of-the-art PV connectors.

[0029] Both the male connector 1 and the female connector 2 of the present invention are made of insulating resin, preferably polycarbonate, and have a corrugated outer surface to provide better engagement. When the male connector 1 and the female connector 2 as image 3 When assembled together as shown for use as the PV connector of the present invention, the male connector 1 and the female connector 2 are attached by a locking device having locking pieces 3 on both sides for engaging each other. Synthetic locking structure.

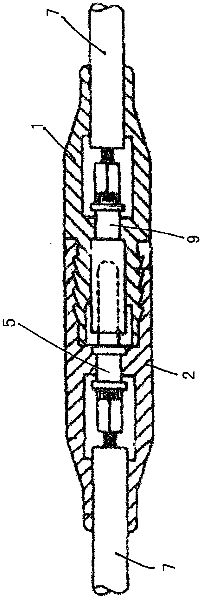

[0030] The female connector 2 is a receptacle shell with a tubular socket 4. The interior of the tubular socket 4 surrounds a tubular male terminal 5 made of PH bronze p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com