Heating blow-off apparatus

A technology of air supply device and heating unit, applied in hair drying device, hair or scalp washing device, clothing, etc., which can solve problems such as high cost, poor assembly, and inability to dry scalp

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

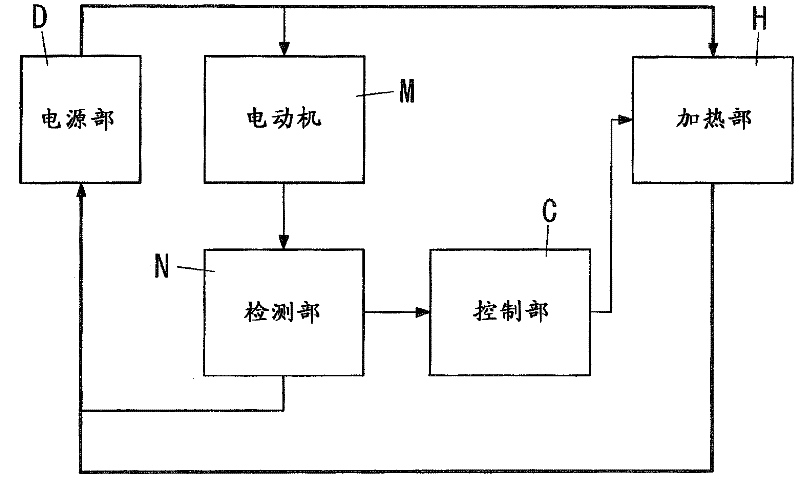

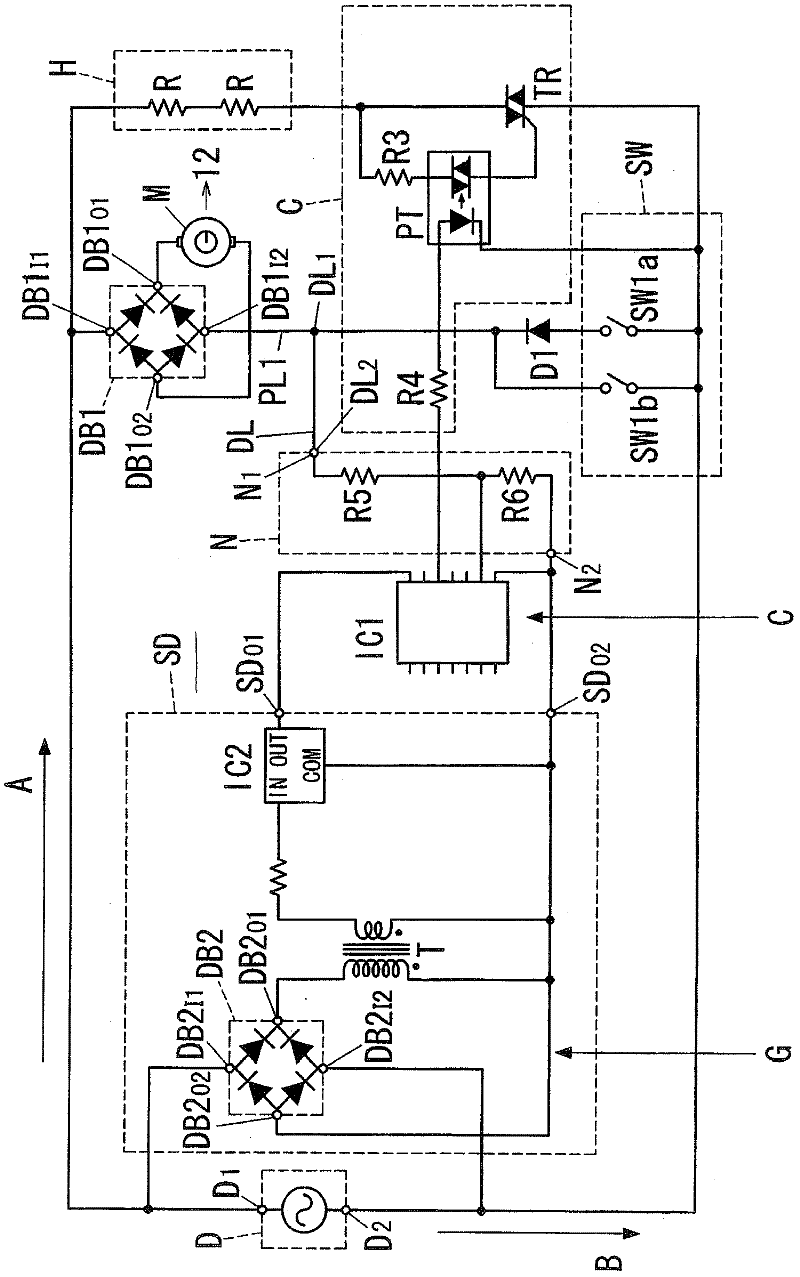

[0024] One embodiment of the present invention will be described based on the drawings. The heating and air blowing device of this embodiment is connected to the power supply unit D and used. Such as figure 1 As shown, the heating air supply device has: used to drive the fan (refer to Figure 7 12) of the motor M; the heating part H for heating the air flowing by the fan; the detection part N for detecting the voltage or current that energizes the motor M; and receiving the signal from the detection part N (detection result) And the control part C which controls the electric power supplied to the heating part H. As shown in FIG. For example, the control unit C is configured to perform duty ratio control of the electric power supplied to the heating unit H in a preset state corresponding to the detection result.

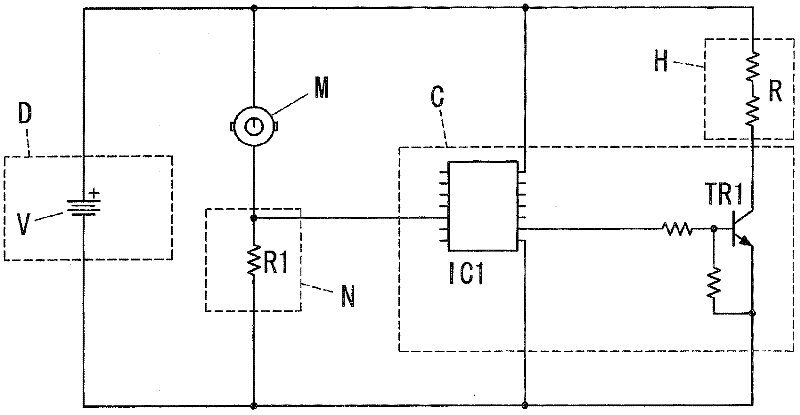

[0025] figure 2 This is an example in which the power supply unit D is a DC power supply V. In this example, the heating part H is a resistor R, and the detecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com