Process equipment for laser machining air film group holes and shape of multi-ring wave large heat shield

A technology of laser processing and process equipment, which is applied in laser welding equipment, metal processing equipment, welding equipment, etc., can solve problems such as difficult to realize one-time clamping processing, insufficient stroke of three-coordinate laser system, and difficulty in reliable and accurate positioning of parts, etc., to achieve The effect of increasing the machining stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

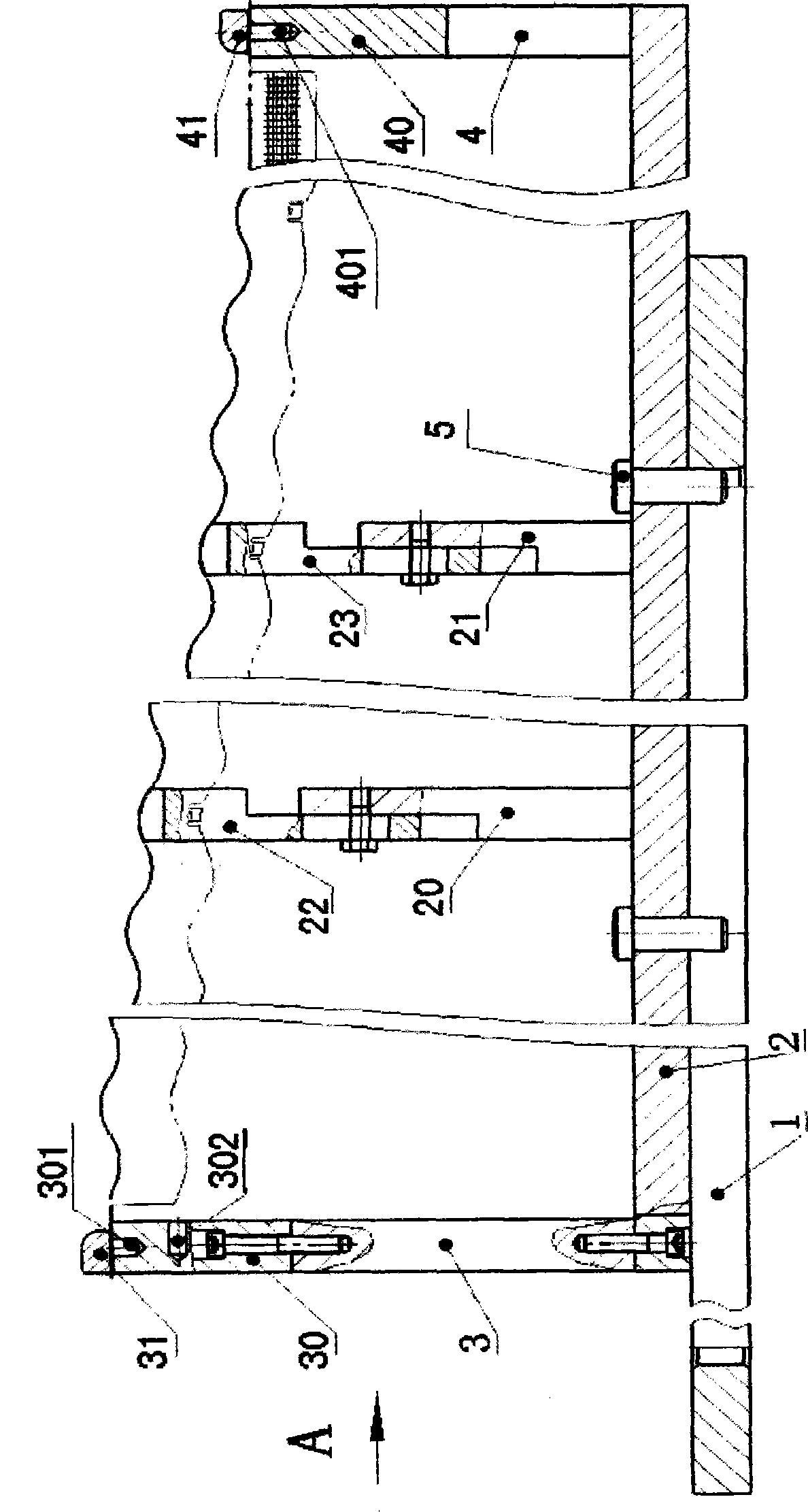

[0025] The process equipment for the laser processing of the gas film group holes and the shape of the multi-ring wave large heat shield described in this embodiment is realized by the station 1 and the station 2 during the processing process, and the sliding bottom plate (2) is used to fix the bottom plate (1) Sliding, changing the position of the process equipment, realizing the switch between station 1 and station 2.

[0026] The parts to be processed in this embodiment are annular structural parts that will be placed inside the engine afterburning cylinder and are perpendicular to the cylinder axis. The heat shield is a complex stamping and formed part of a thin-walled plate, and its unfolded shape is a multi-wave conical sector. The length is 1m and the width is 0.5m. After processing, there are more than 10,000 tiny air film group holes with a diameter of only 1mm distributed on the part profile, and the normal direction of these holes is perpendicular to the part profile...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap