Cover mould device with unconfined compression strength for inorganic binder

A technology of inorganic binder and compressive strength, applied in the direction of ceramic molding machines, manufacturing tools, etc., can solve the problems of reducing test efficiency, large disturbance of test pieces, and affecting strength, so as to improve test efficiency, reduce disturbance and small disturbance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

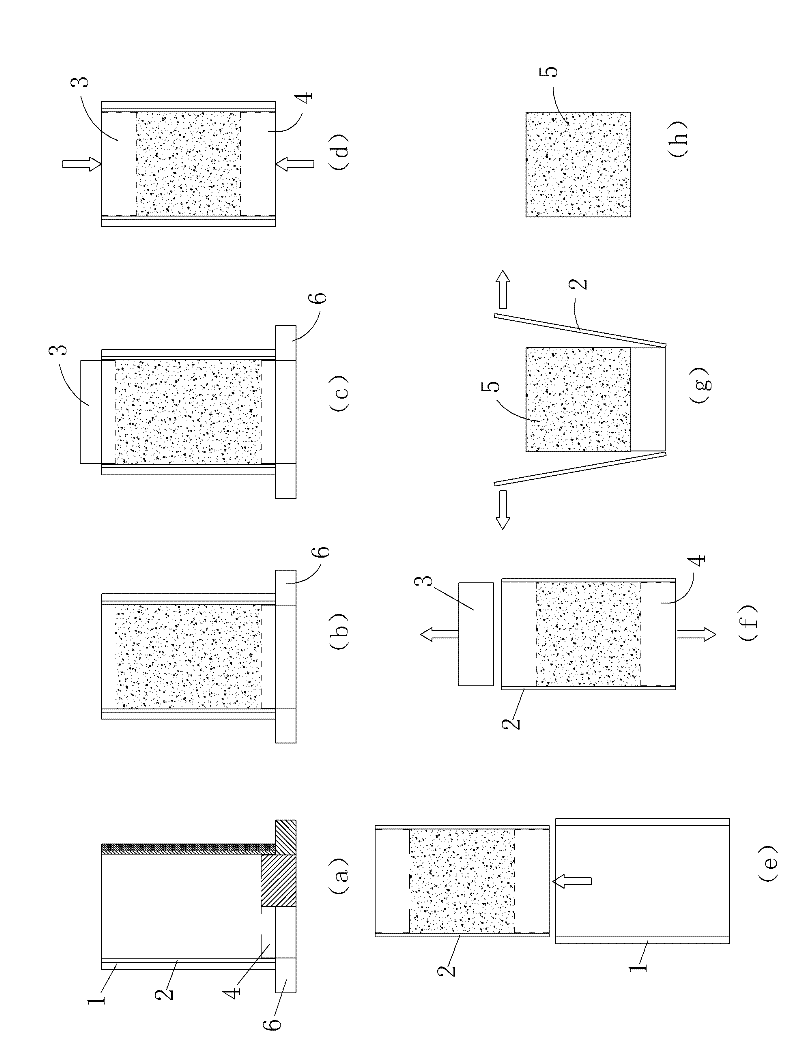

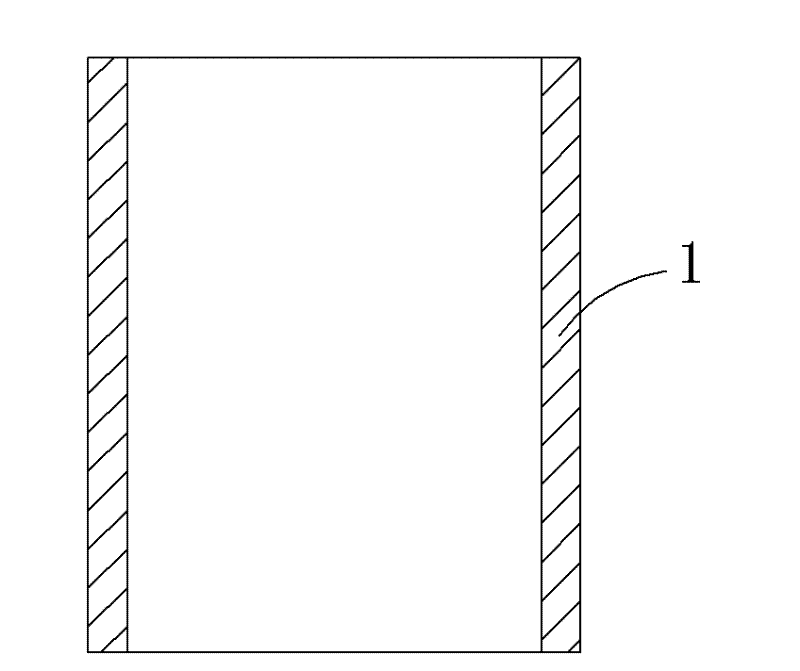

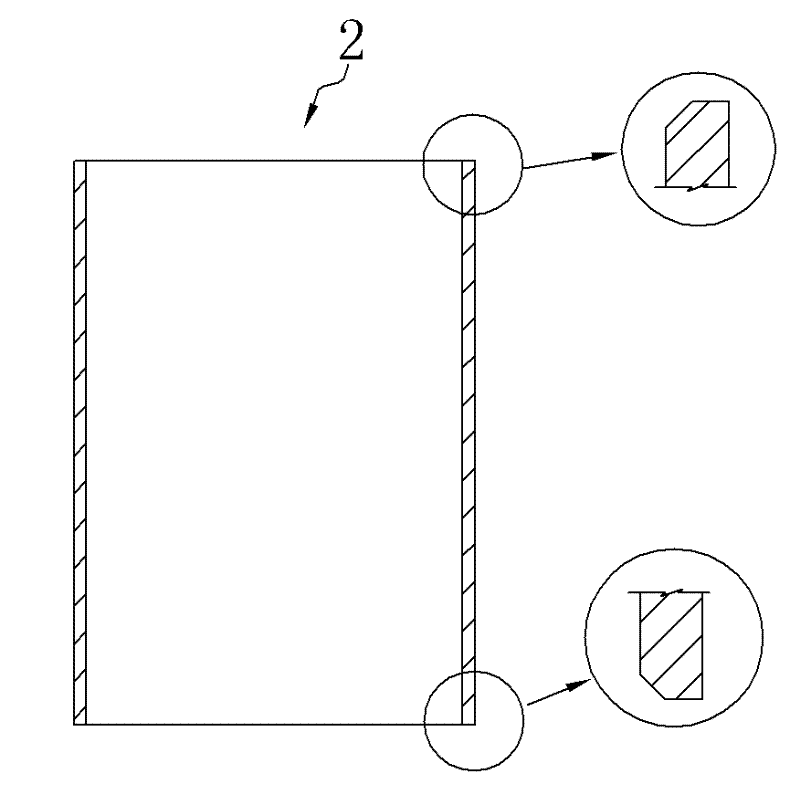

[0045] see Figure 1 to Figure 7 As shown, an inorganic binder unconfined compressive strength sleeve mold device proposed in the embodiment of the present invention includes an outer mold 1 and an inner mold 2 that can be detached laterally, and the inner mold 2 is cooperatively connected inside the outer mold 1. The upper and lower parts of the inner mold 2 are respectively provided with upper and lower pressure pads 3 and 4 .

[0046] When the mold set device is in use, the inner mold 2 is first assembled inside the outer mold 1, and the lower pressure cushion block 4 is installed under the inner mold 2, then the inorganic binder is installed inside the inner mold 2, and then the inner mold 2 is placed above the inner mold 2. Install the upper pressure pad 3, at this time, the upper and lower pressure pads 3 and 4 are respectively located at the upper and lower positions of the inorganic binder, so that the upper and lower pressure pads 3 and 4 apply pressure to the middle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com