Pedal capable of improving stepping efficiency and manufacturing method thereof

A pedal and pedal technology, applied in crank structure, transportation and packaging, vehicle parts, etc., can solve the problems of large wind resistance, heavy weight and poor riding comfort of the pedal, and achieve increased riding speed and less deformation. Damage and wind resistance reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific embodiments.

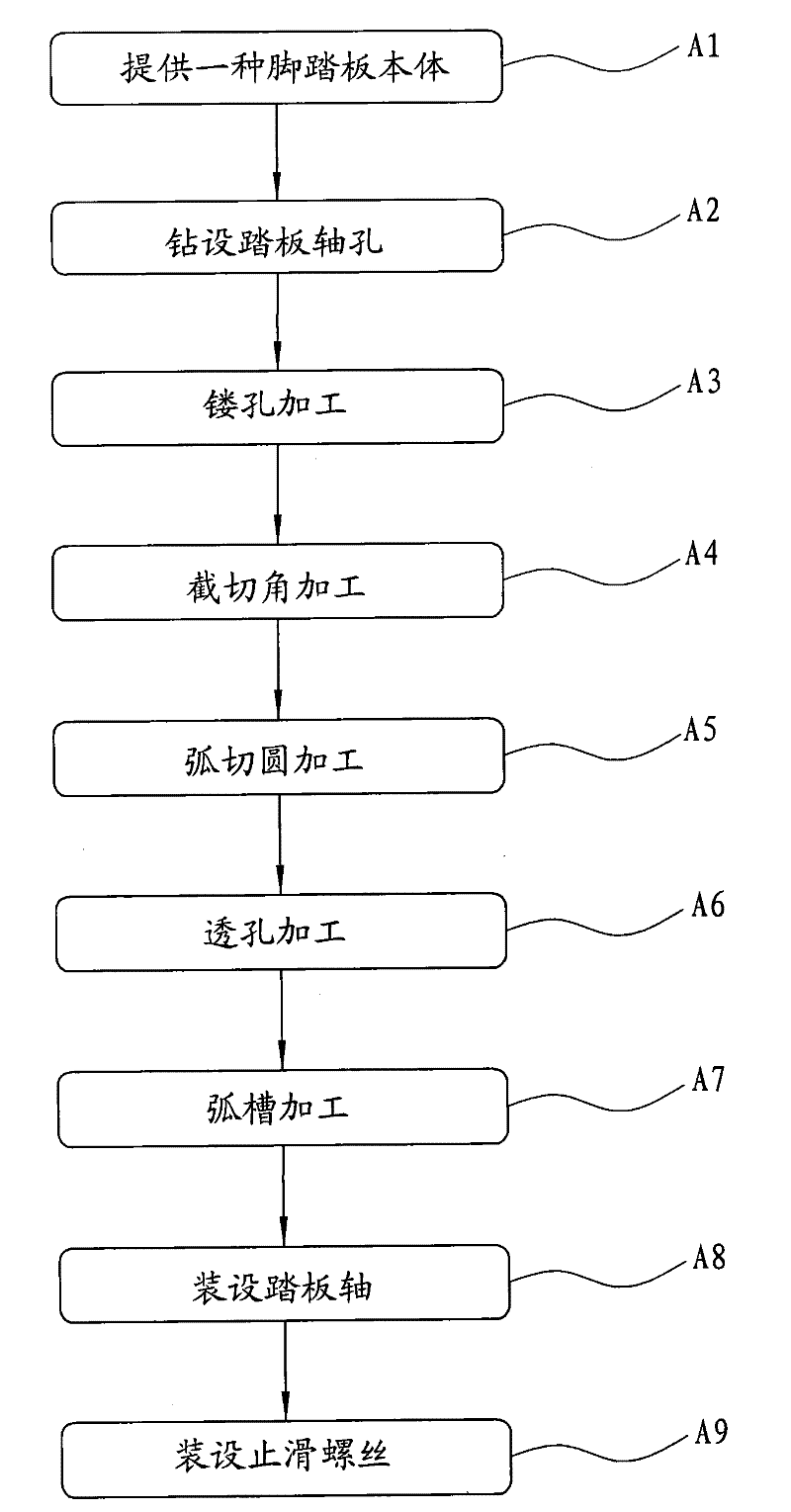

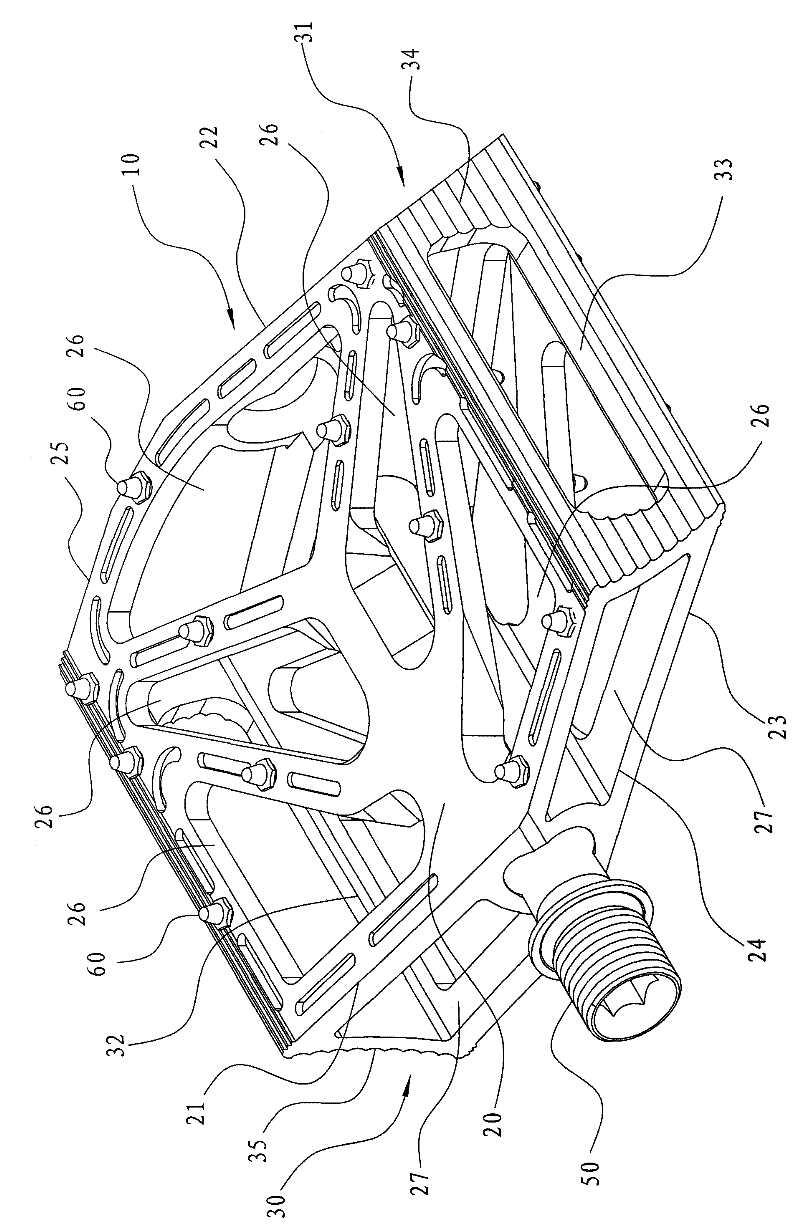

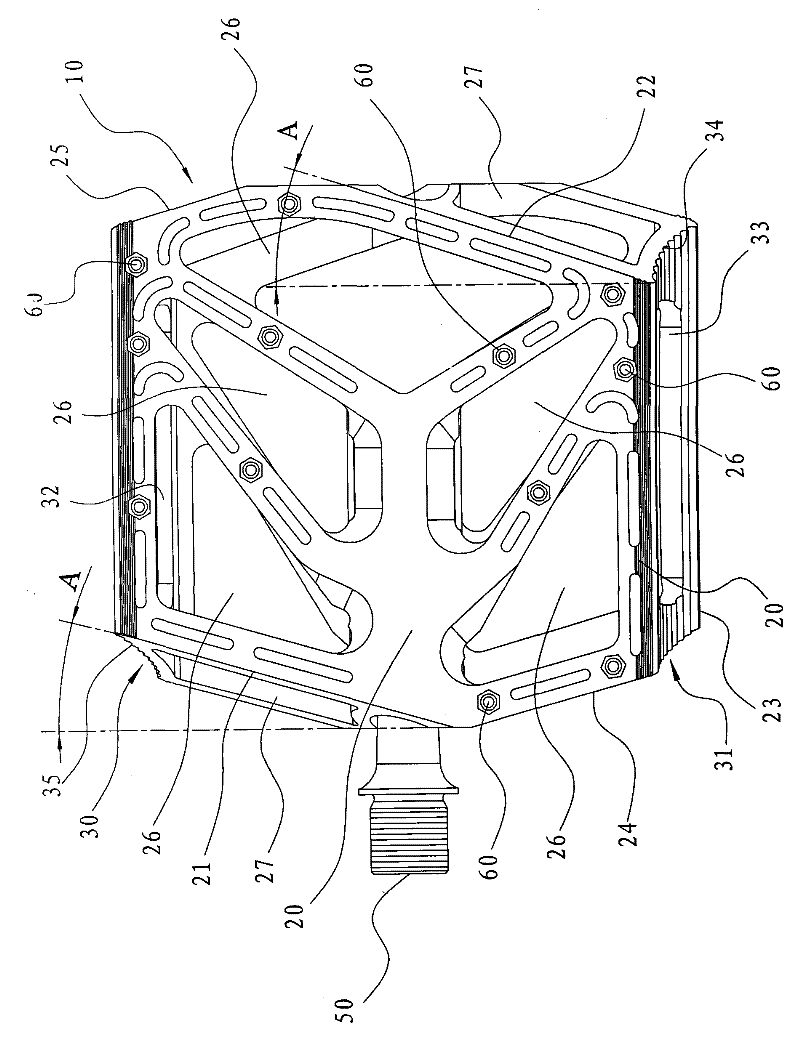

[0041] See Figure 1 to Figure 6B As shown, the present invention relates to a pedal that can improve pedaling efficiency. It is mainly provided with a symmetrical top pedaling surface 20 and a bottom pedaling surface 23 at the top and bottom ends of a pedal body 10. The top pedaling surface 20 The upper left and right edges are provided with truncated angles 21 and 22 for outward expansion angles, and the left and right edges of the bottom tread surface 23 are also provided with truncated angles 24 and 25 for outward expansion angles, on the same surface The two truncated angles 21, 22 or 24, 25 are parallel to each other, and the angle A is suitable for outward expansion. The outward expansion angle A is between 5 degrees and 25 degrees, which can conform to the slightly outward expansion angle of the human f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com