Flywheel mechanism for hammer of light electric piling machine

A technology of pile driver and hammer head, which is applied in the direction of sheet pile wall, foundation structure engineering, construction, etc. It can solve the problems of time-consuming, laborious, and inability to use large-scale piling equipment, etc., and achieves good effect and increased hammering energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

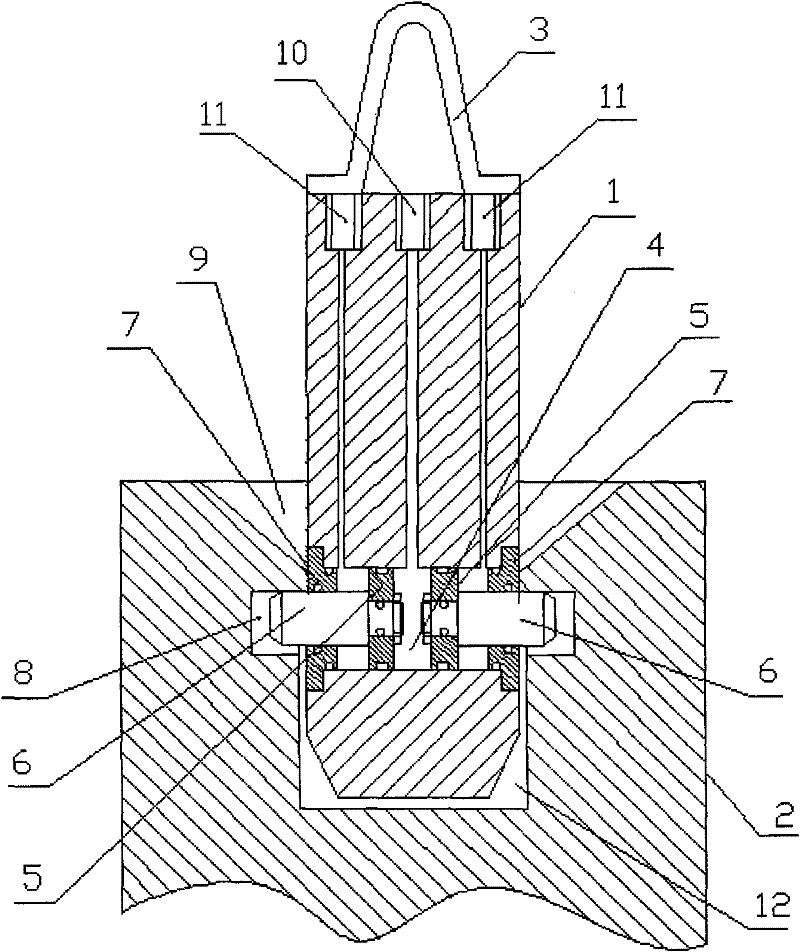

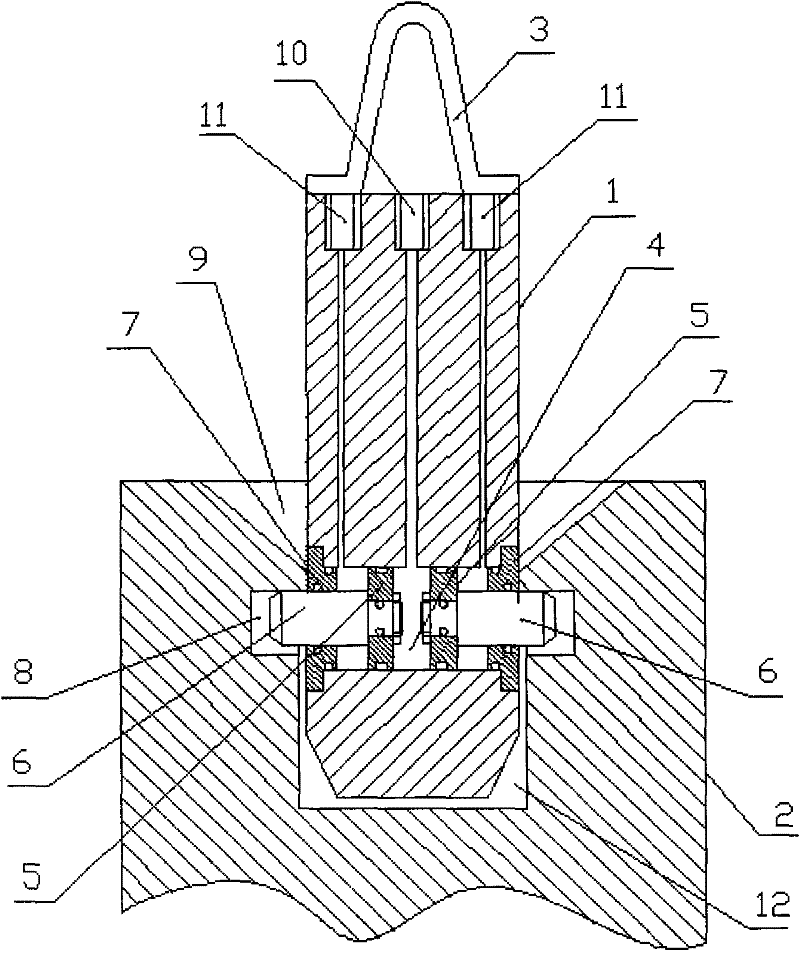

[0008] A blind hole 12 is formed in the middle of the hammer head 2, and the upper mouth of the blind hole 12 is formed with a bell mouth 9, and the middle end of the blind hole 12 is formed with an annular groove 8. The left and right hydraulic cylinders 4 are symmetrically installed in the middle of the hydraulic cylinder 4. Two pistons 6 are installed on each of the two pistons. The cylinder cover 7, the cylinder cover 7 seals the mouth of the hydraulic cylinder 4, and an oil inlet 10 is formed in the center of the hanging hammer 2, and the oil inlet 10 communicates with the middle of the hydraulic cylinder 4, and two holes in the center of the hanging hammer 1 Each side is formed with an oil return hole 11, and the oil return hole 11 communicates with the piston rod cavity on the left and right sides of the hydraulic cylinder 4 respectively, and the lifting ring 3 is installed and fixed on the top of the hanging hammer 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com