A kind of sandblasting layer stripping method for combined hammering and cutting to remove damaged environmental barrier coating

An environmental barrier and coating technology, applied in the coating field, can solve the problems of EBC peeling and scrapping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

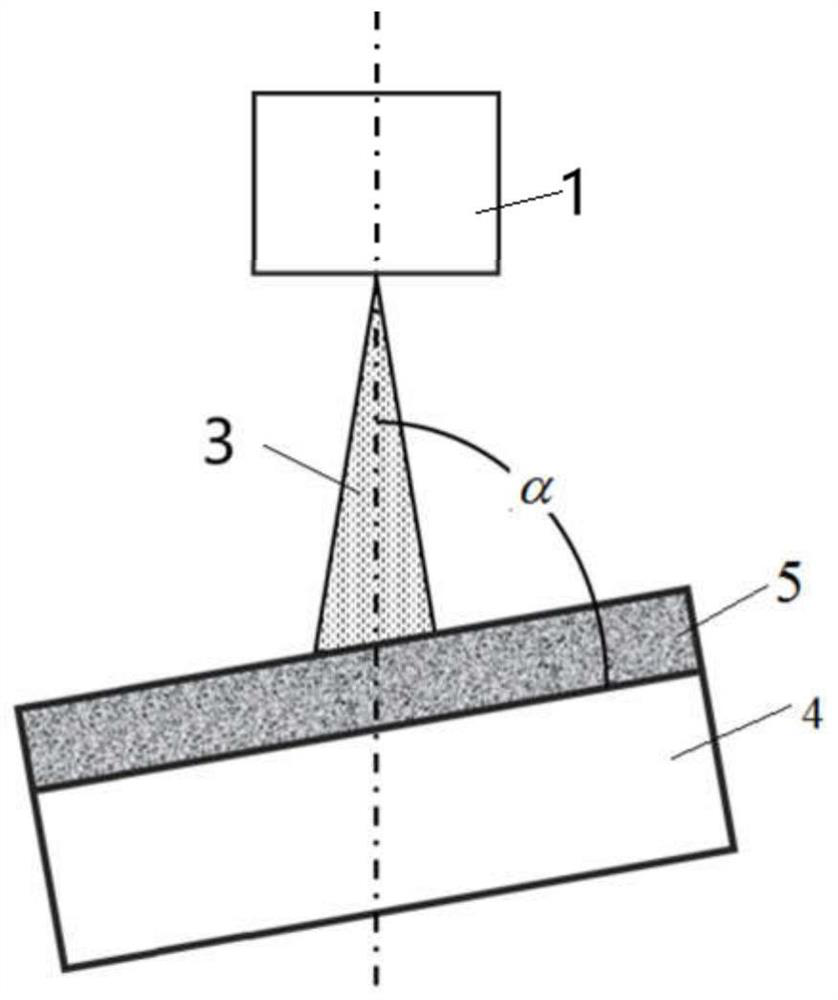

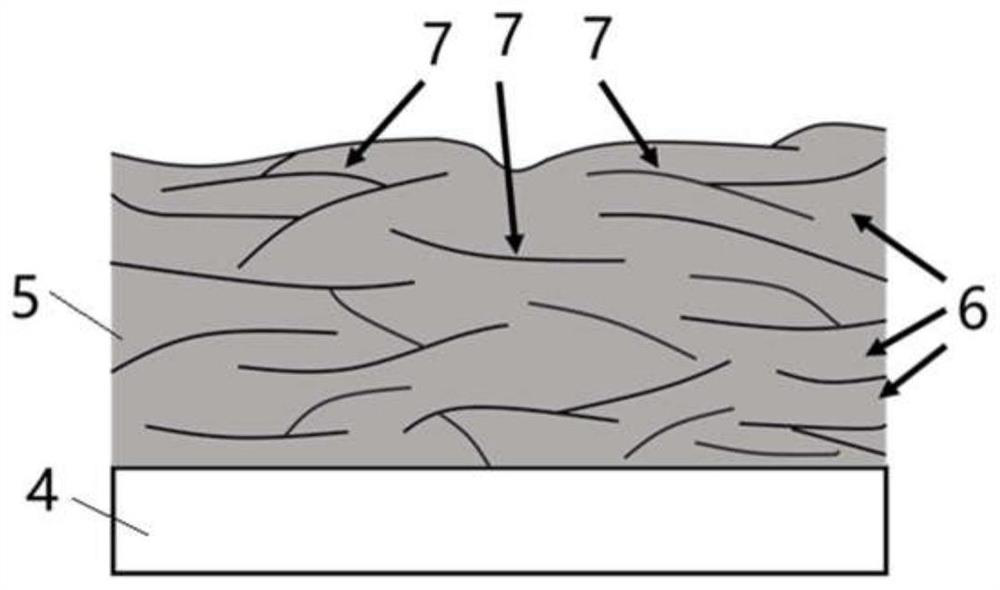

[0032] see Figure 1 to Figure 3 As shown, the preparation method of the present invention is illustrated by taking alumina sand to remove the ytterbium silicate coating on the surface of the silicon carbide-based ceramic matrix composite material as an example. The micro-Vickers hardness of the alumina used is 19-21.6GPa, the micro-Vickers hardness of the silicon carbide of the matrix is more than 30GPa, and the micro-Vickers hardness of the ytterbium silicate is less than 10GPa. Therefore, the selected removal grit meets the requirement that the hardness is less than that of the substrate and greater than that of the coating.

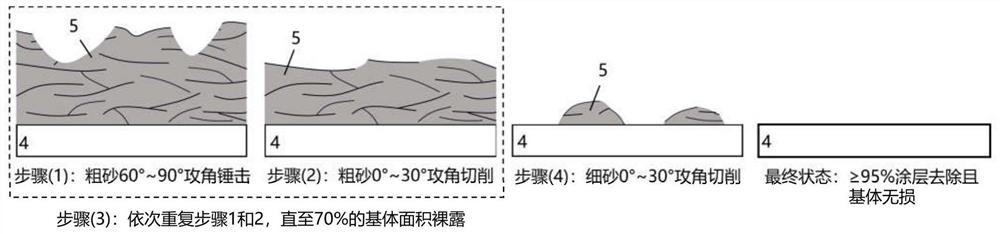

[0033] The invention provides a sandblasting layer stripping method for combined hammering and cutting to remove a damaged environmental barrier coating, comprising the following steps:

[0034] Step 1, use spherical alumina sand particles with a particle size of 800-1000 μm, and use a sandblasting machine to damage the environmental barrier coatin...

Embodiment 2

[0039]The difference between this example and Example 1 is that in steps 1 and 2, the particle size of the coarse sand is 650-800 μm, the angle of attack in step 1 is 75°, the angle of attack in step 2 is 15°, and the removal time is 2min. In step 4, the environmental barrier coating 5 is damaged by erosion at an angle of attack of 30° by using polygonal alumina sand grains with a particle size of 50 μm to 450 μm until 95% of the substrate area is exposed and the substrate is intact.

Embodiment 3

[0041] The difference between this example and Example 1 is that in steps 1 and 2, the particle size of the coarse sand is 500-650 μm, the angle of attack in step 1 is 60°, the angle of attack in step 2 is 0°, and the removal time is 1min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com