A shoe sole hammer flattening machine

A technology for hammering and shoe-making, which is applied in the field of shoe-making equipment. It can solve the problems of laborious manual cleaning, uneven beating positions, and complicated structure of the hammering machine, so as to improve the hammering effect, improve the flatness, and improve the quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

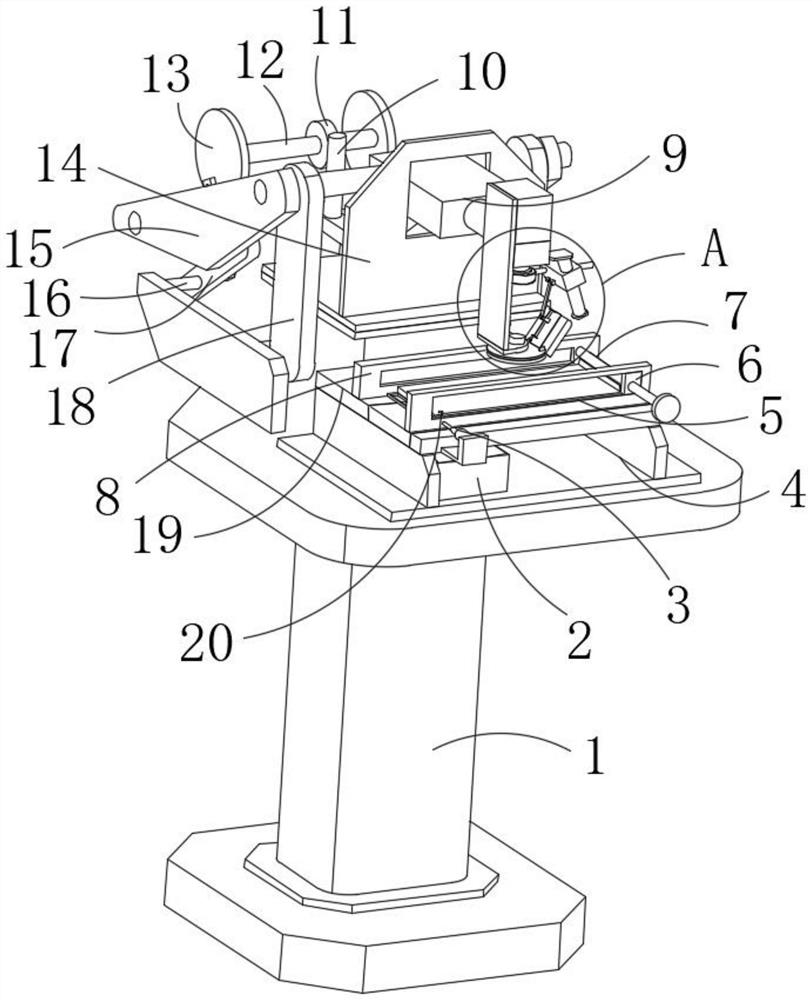

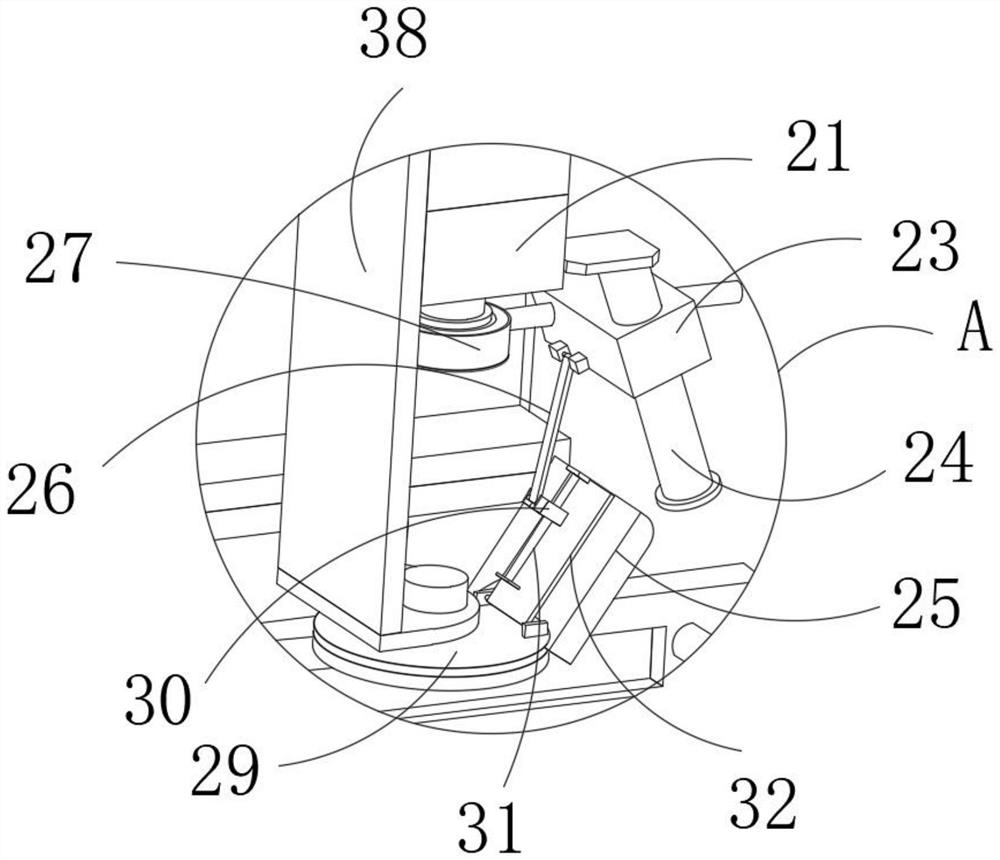

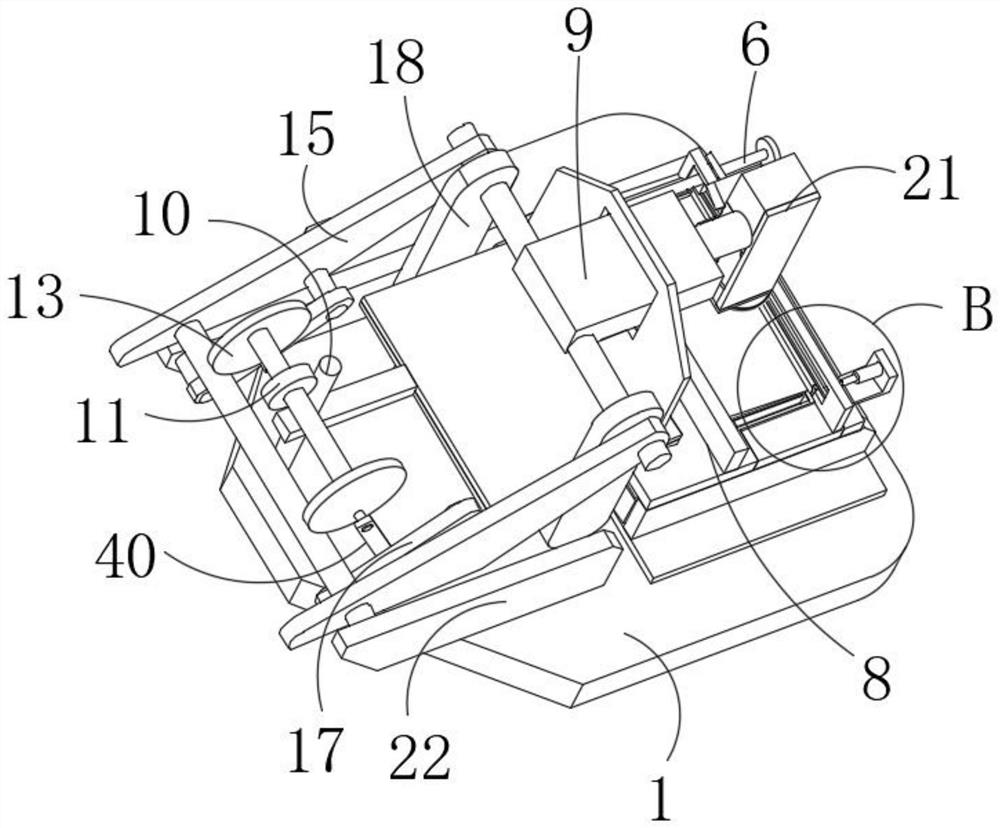

[0035] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 As shown, the present embodiment proposes a shoe sole hammer flat machine, including a body 1, a hammer flat frame 4 is fixedly installed on the upper surface of the body 1, and a load-bearing plate 19 is fixedly connected to the upper end of the hammer flat frame 4, which bears the load. The upper end of the plate 19 is provided with two baffles 8, the upper end of the body 1 is fixedly installed with a fixed plate 14, the upper surface of the body 1 is installed with a swing mechanism, and one end of the fixed plate 14 is provided with a hammer leveling mechanism, which includes: The top frame 38 is fixedly installed on one end of the fixed plate 14, the bottom end of the top frame 38 is fixedly installed with the hammer head 29, the upper surface of the hammer head 29 is rotatably installed with the back plate 32, and one end of the back plate 32 is fixedly connected...

Embodiment 2

[0037] The scheme in Embodiment 1 is further introduced below in conjunction with the specific working mode, and is described in detail below:

[0038] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8As shown, as a preferred embodiment, on the basis of the above-mentioned method, the swing mechanism further includes two side plates 22 fixedly installed on the upper surface of the fuselage 1, and a connecting rod 16 rotatably installed with the side plates 22. One end of the rod 16 is rotatably installed with a pulling rod 17, the upper part of the fixed plate 14 is interspersed with a swing block 9, and one end of the swing block 9 is movably installed with two swing plates 15, and the corresponding sides of the two swing plates 15 are rotatably connected There is a main board 18, the main board 18 is rotatably connected with the side plate 22, the traction rod 17 is rotatably connected with the swing plate 15, one end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com