Automatic dredging device for chlorine spray gun of molten salt chlorination furnace

A molten salt chlorination furnace and chlorine technology, which are applied in injection devices, titanium tetrachloride, titanium halide and other directions, can solve the problems of low efficiency, time-consuming and laborious chlorine spray gun dredging, etc., and achieve high efficiency, eliminate potential safety hazards, hammer blow powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

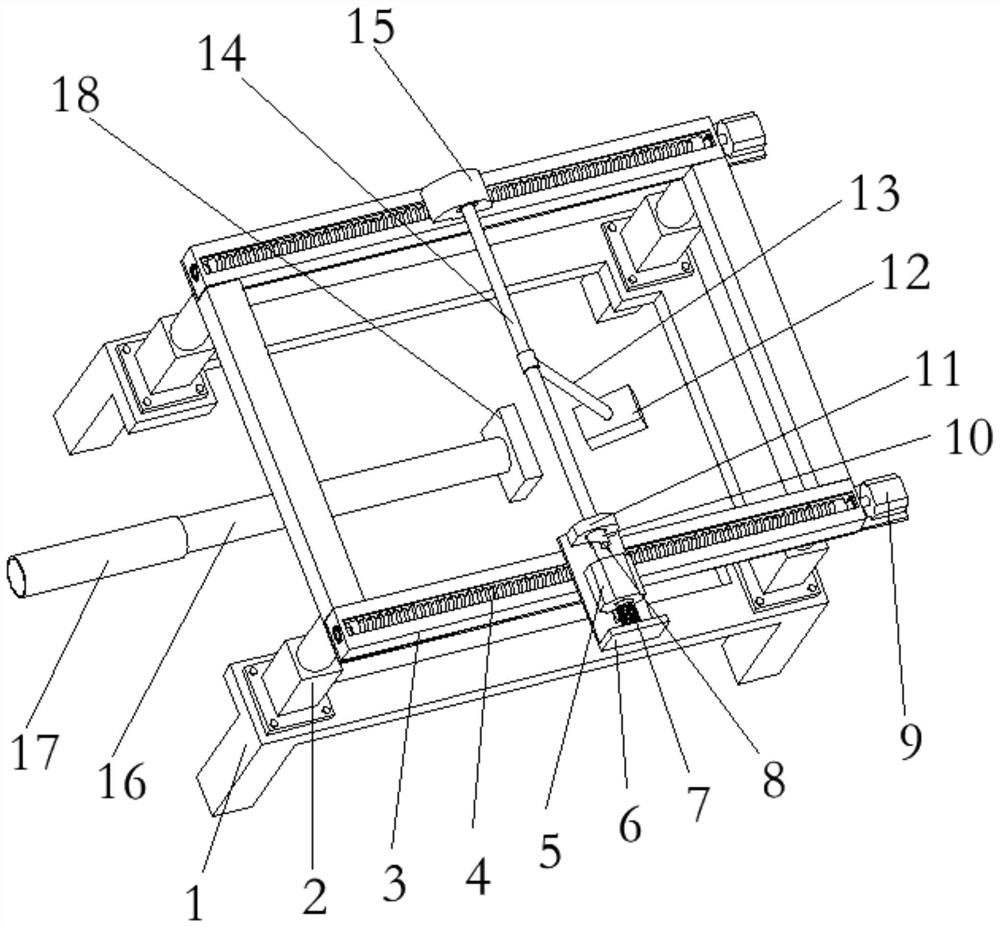

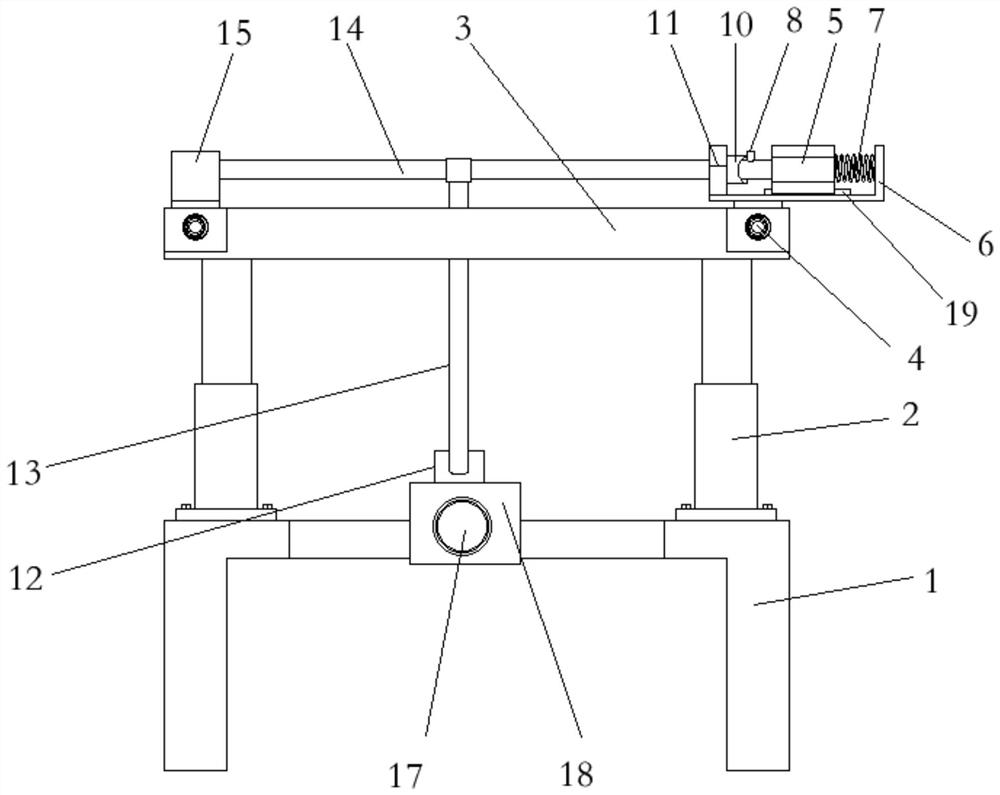

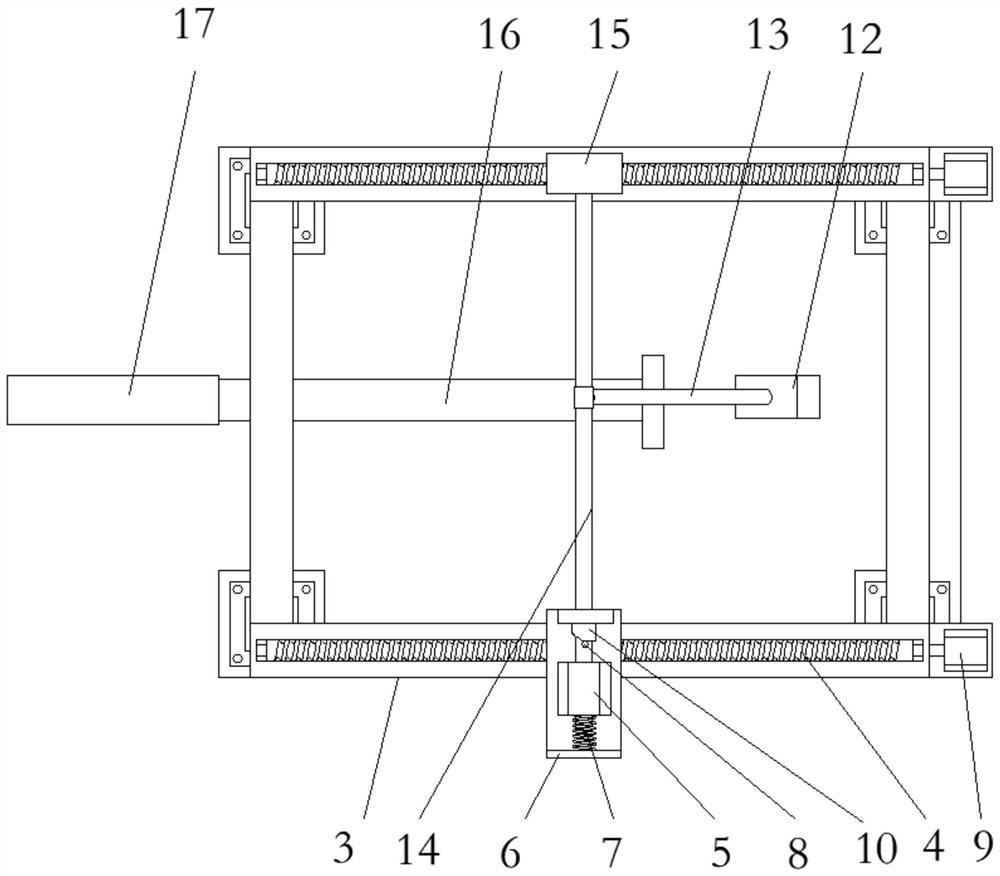

[0047] A kind of molten salt chlorination furnace chlorine spray gun automatic dredging device, such as figure 1 As shown, it includes a base 1 and a chlorine spray gun needle 16. The base 1 is provided with a lifting platform, and the lifting platform includes four hydraulic cylinders 2 and a moving frame 3 at the top of the hydraulic cylinders 2. The bottom of the lifting mechanism It is fixedly connected with the base 1, and the top is fixedly connected with the motion frame 3. Both sides of the moving frame 3 are provided with a longitudinal movement mechanism, and the longitudinal movement mechanism includes two linear modules respectively arranged on both sides of the moving frame 3 , and the linear modules include a servo motor 9 and a lead screw 4 . Both the second drive shaft mount 15 and the motor base 6 are connected to the lead screw 4 . The servo motor 9 drives the screw 4 to rotate, which can make the second transmission shaft mounting base 15 and the motor base...

Embodiment 2

[0057] The technical solution of this embodiment is basically the same as that of Embodiment 1, the difference is that in this embodiment, the motor 5 is fixed on the motor mount 6, the output shaft of the motor 5 is connected with a half gear 20, and the transmission shaft 14 is connected with full gear 21, and said full gear 21 cooperates with half gear 20.

[0058] When the motor output shaft 22 rotates, when the half gear 20 meshes with the full gear 21, the motor 5 drives the transmission shaft 14 to rotate, thereby driving the weight 12 to move upward. When the half gear 20 rotates to disengage from the full gear 21, the weight The hammer 12 has been raised to the highest point and moves downward from the highest point to hammer the needle cap 18 . When the half gear 20 is meshed with the full gear 21 again, the weight 12 is promoted again, and so reciprocated, the dredging of the chlorine gas spray gun is realized.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com