Construction desk frame for large-cross-section hole type spillway

A spillway and large-section technology is applied in the field of large-section lining concrete construction benches, which can solve problems such as inability to meet, and achieve the effects of ensuring flatness, reducing operating strength, and facilitating correction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

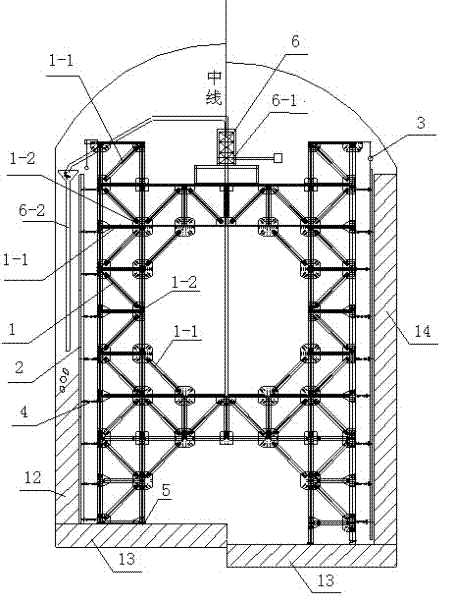

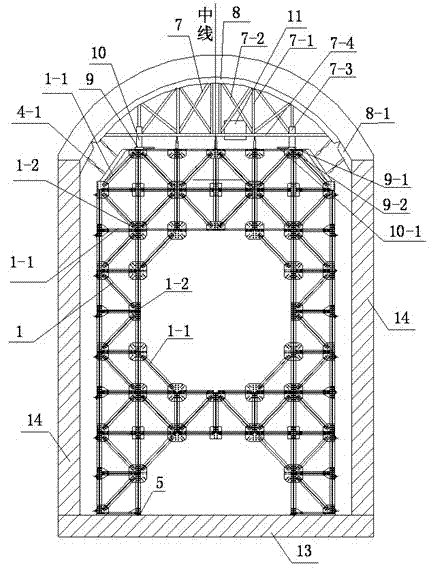

[0035] Embodiment of the present invention: when the lining concrete of the large-section hydraulic cavern is carried out in two steps, the first step is to complete the lining of the side wall concrete of the whole cavern with a cycle of 12 m; the second step is also the same With a cycle of 12 m, the concrete lining of the top arch of the entire cavern is completed. That is, the entire cavern is fully lined.

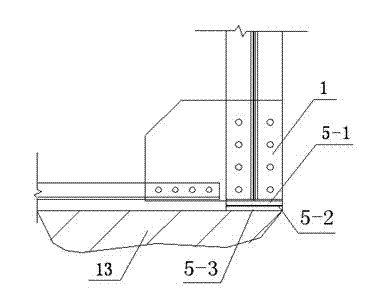

[0036] The stand main body 1 is assembled by rods 1-1 and connecting plates 1-2.

[0037] Side wall formwork 2, using A3 steel plate with δ=6mm as the panel, the longitudinal reinforcement rib is welded with [14a channel steel, and the vertical reinforcement rib is A3 with [14a channel steel and δ=5mm, h=12.5cm, w=5cm Steel plate welding. The complete set of formwork consists of 24 pieces, of which 20 pieces are 6.1m×3m, and 4 pieces are 6.1m×2.5m. The edge of each formwork is connected as a whole with 4 [14a channel steel circles. The templates are connected as a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com