Light guide panel and backlight module

A technology of backlight module and light guide plate, applied in the direction of light guide, optics, optical components, etc., can solve the problem of insufficient light output capability of the backlight module 100, and achieve the effect of good light use efficiency, high uniformity, and improved light use efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

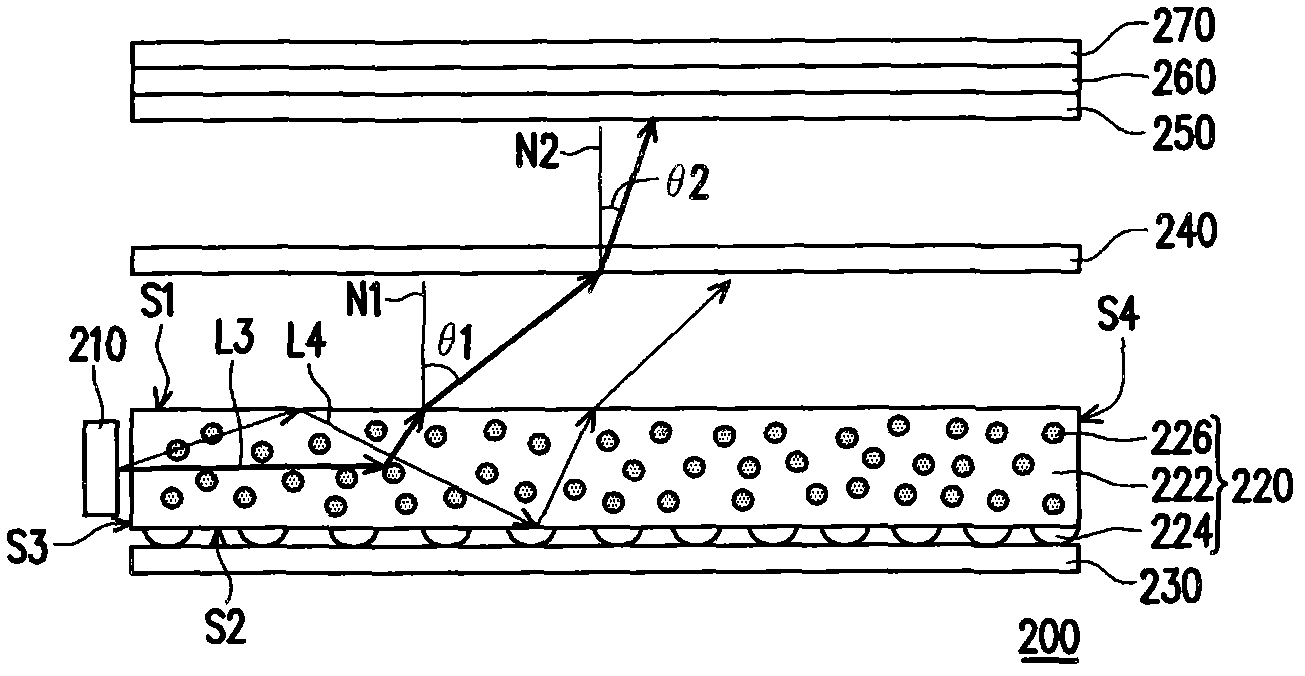

[0050] figure 2 It is a schematic diagram of the backlight module according to the first embodiment of the present invention. Please refer to figure 2 , the backlight module 200 of this embodiment includes a light emitting element 210 and a light guide plate 220 . The light emitting element 210 is used to emit a light beam L3. The light guide plate 220 is disposed beside the light emitting element 210 and is used to guide the light beam L3. In this embodiment, the light emitting element 210 is, for example, a light emitting diode (light emitting diode, LED). The light guide plate 220 includes a transparent substrate 222 , a plurality of optical microstructures 224 and a plurality of diffusion particles 226 .

[0051]The transparent substrate 222 has a surface S1, a surface S2 opposite to the surface S1, a light incident surface S3 connecting the surface S1 and the surface S2, and a surface S4 opposite to the light incident surface S3, wherein the light beam L3 enters thr...

no. 2 example

[0066] Figure 4 It is a schematic diagram of the backlight module according to the second embodiment of the present invention. like Figure 4 As shown, the backlight module 300 with figure 2 The backlight module 200 is similar to the above-mentioned backlight module 200, the main difference between the two is: the optical microstructure 224 of the backlight module 300 is configured on the surface S1. Since the backlight module 300 of this embodiment can be composed of Figure 2 ~ Figure 3B There are sufficient teachings, suggestions and implementation descriptions obtained in the description of the embodiments, so the details are not repeated here.

no. 3 example

[0068] Figure 5 It is a schematic diagram of the backlight module according to the third embodiment of the present invention. like Figure 5 As shown, the backlight module 400 with figure 2 The backlight module 200 is similar to the backlight module 200, but the main difference is that the backlight module 400 also includes a light-emitting element 280, and the light-transmitting substrate 222' also has a light incident surface S4' opposite to the light incident surface S3, wherein The light emitting element 280 is disposed beside the light incident surface S4'.

[0069] like Figure 5 As shown, the light-emitting element 280 is used to emit the light beam L5, and since the diffusion particles 226 are added inside the light-transmitting substrate 222 ′, the light beam L5 will change its trajectory due to collision with the diffusion particles 226 , and then directly pass through the surface S1 to the light-transmitting substrate 222 ′. outside the substrate 222'. In thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| haze | aaaaa | aaaaa |

| haze | aaaaa | aaaaa |

| haze | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com