Modular microstructure light guide device

A light guide device and microstructure technology, applied in lighting devices, components of lighting devices, optics, etc., can solve the problems of large number of light sources, high manufacturing technology requirements, and low degree of freedom in the application of light guide devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The invention is a modularized microstructure light guiding device, which is used for light guiding of car lights, can make the light even and not dazzling, improve the safety of driving at night, and make the car lights produce a light-type lighting effect.

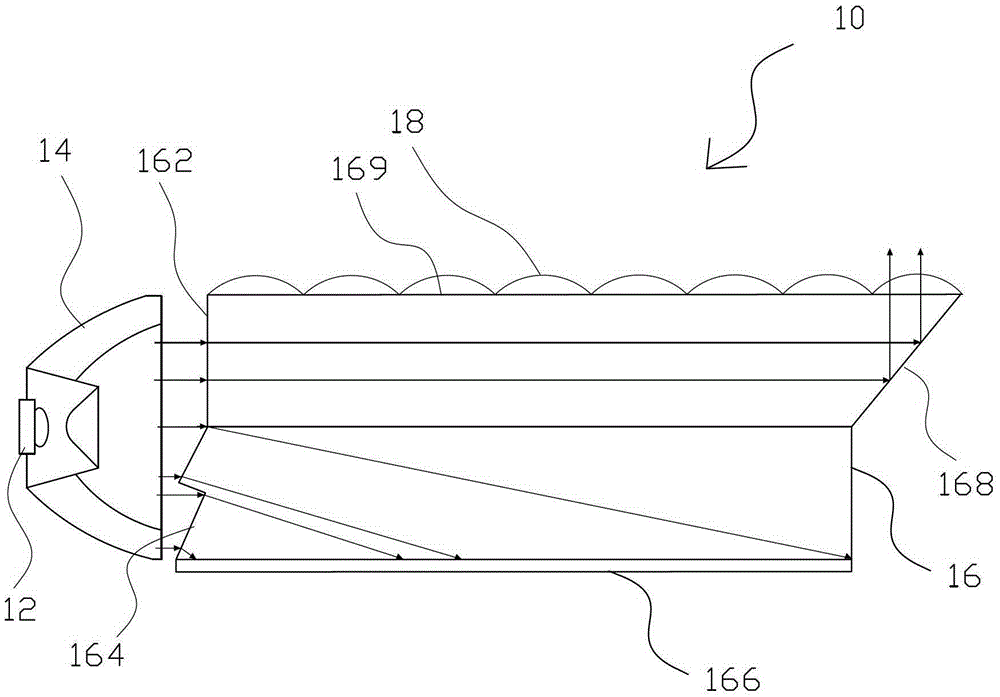

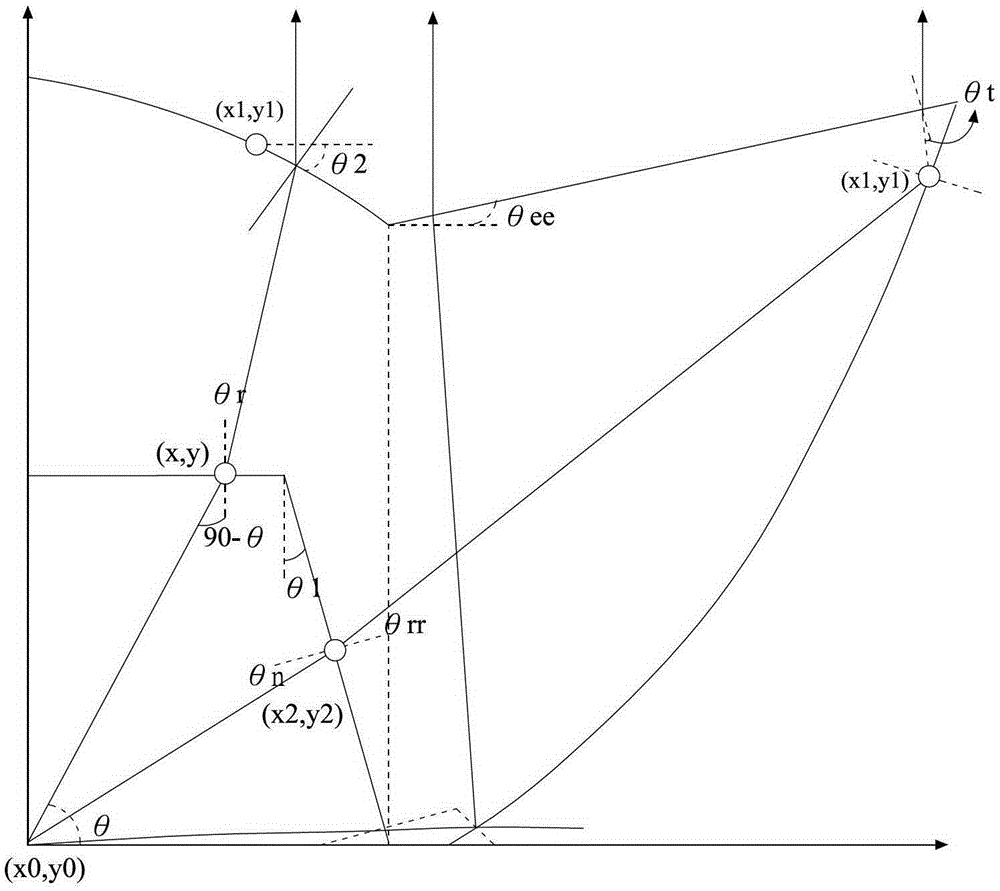

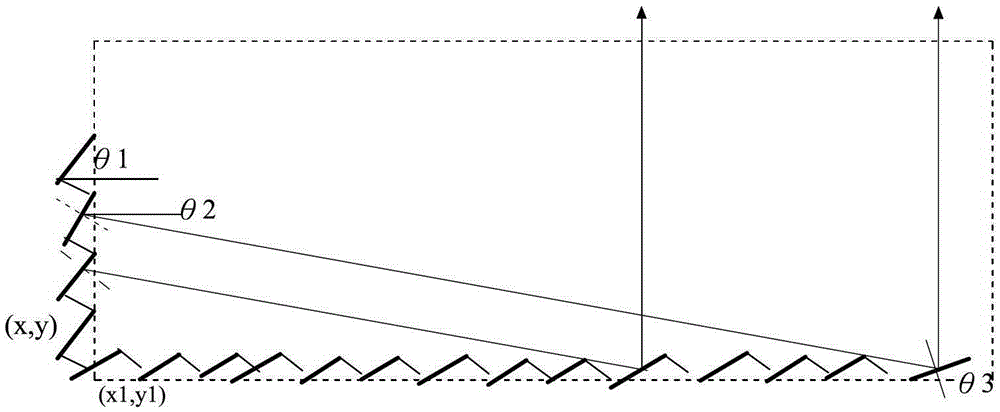

[0022] Please refer to figure 1 , which is a schematic diagram of a microstructure light guide unit in the modular microstructure light guide device of the present invention, the microstructure light guide unit 10 includes a light source 12, an optical coupling element 14 and a light guide body 16, wherein the light source 12 and The light coupling element 14 is placed on the side of the structure of the light guide 16 to provide the light required by the lamp. The light source 12 can be an LED; 166, the total reflection area 168 and the four parts such as the exit surface 169, the optical coupling element 14 is used to emit the light of the light source 12 in parallel, and the first incident surface 162 and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com