Aluminum pore-filling connection process

A connection and process technology, applied in the field of semiconductor manufacturing process, can solve the problems of low film forming rate, easy formation of voids in aluminum filling holes, affecting the throughput of film forming equipment, etc., and achieve the effect of reducing the impact of throughput and lowering requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

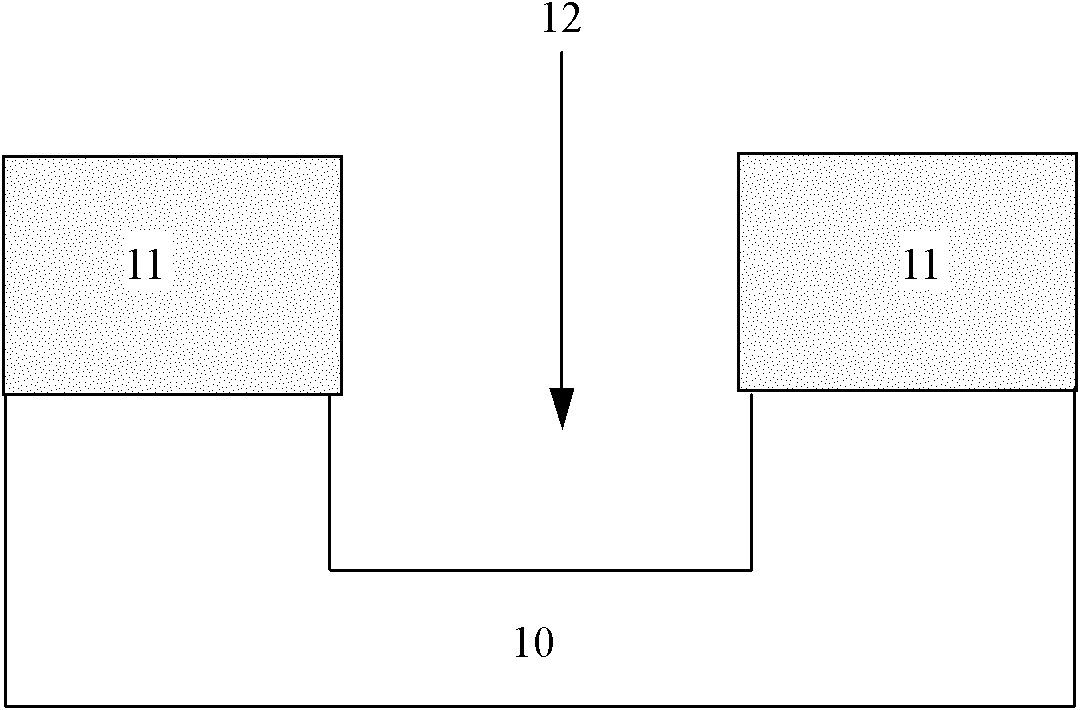

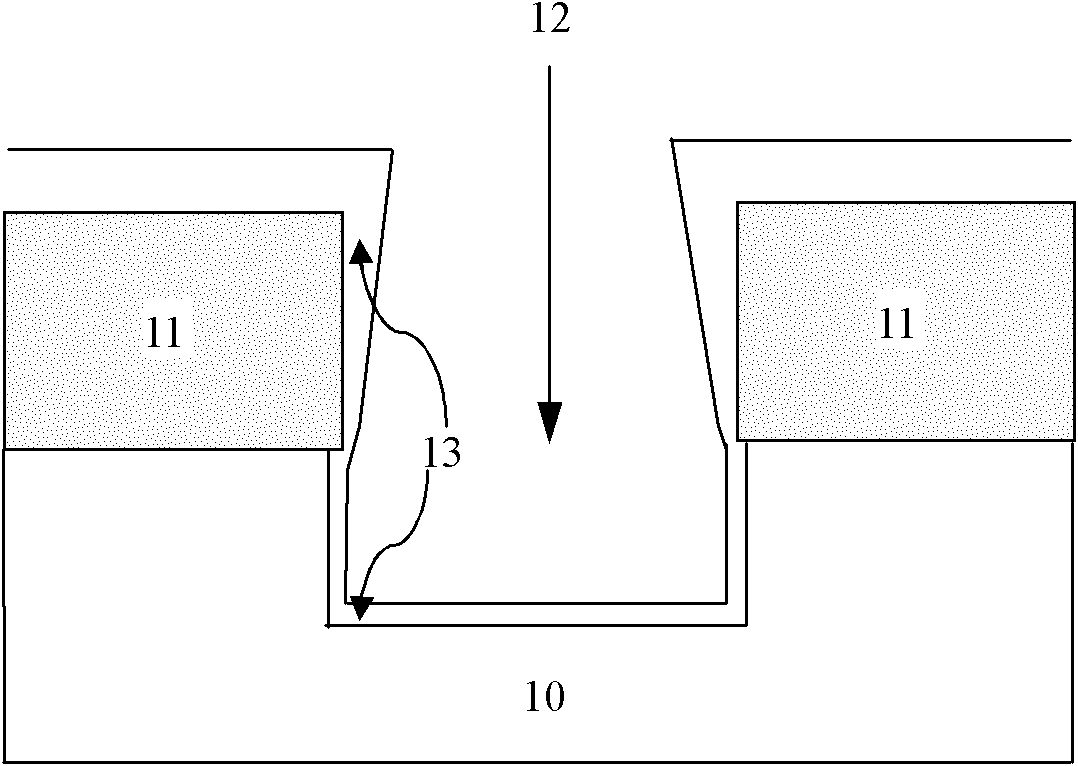

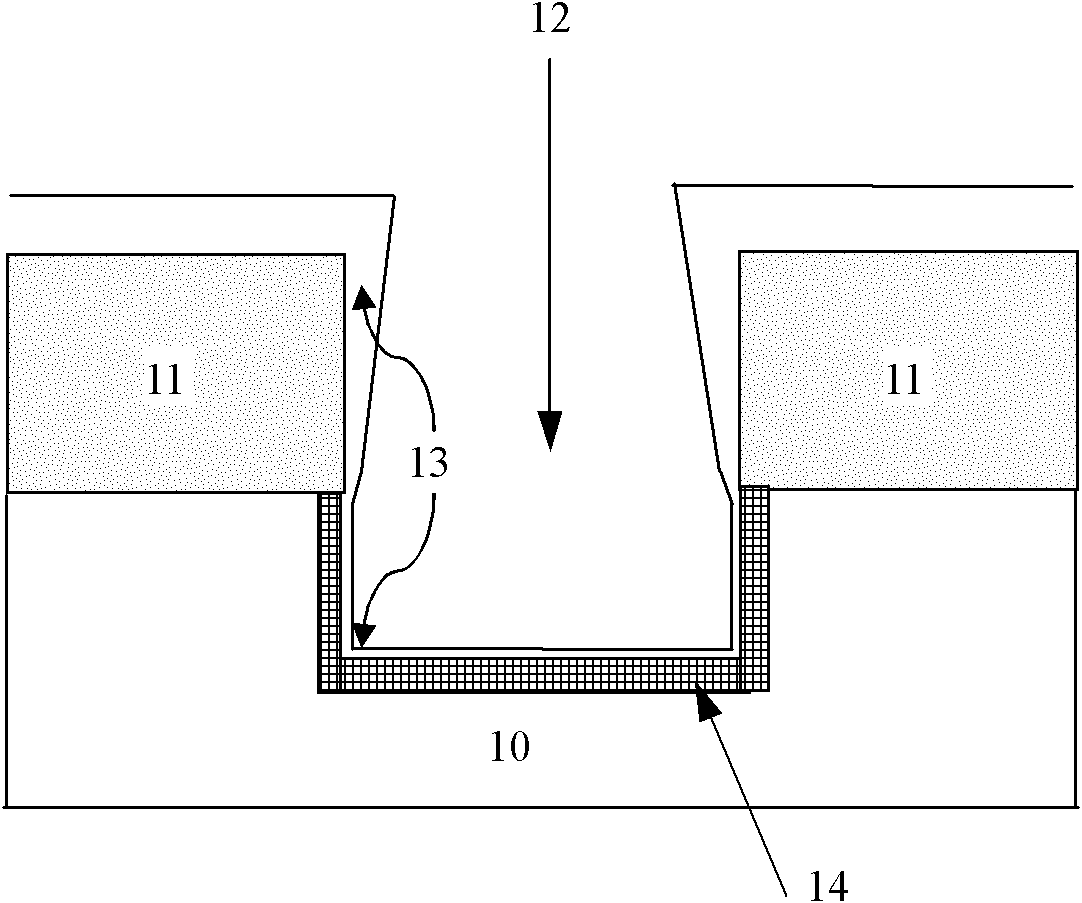

[0019] An embodiment of the aluminum filling hole connection process of the present invention is as follows: Figure 2 ~ Figure 4 shown, including the following steps:

[0020] 1. Deposit a layer of metal (titanium) on the silicon wafer, such as figure 2 As shown, a layer of metal (titanium) 13 is deposited on the oxide film (silicon dioxide) 11 on the silicon wafer and the surface of the silicon 10;

[0021] 2. The metal (titanium) 13 deposited on the silicon wafer reacts with silicon 10 to form an alloy (titanium-silicon alloy) 14 by means of thermal annealing, such as image 3 Shown; The top half of the wall of the hole 12 that needs to be filled on the silicon chip is that the oxide film will not react with the metal (titanium) 13 deposited on the silicon chip, so the volume does not change, and the hole 12 that needs to be filled on the silicon chip Because the lower half of the wall is made of silicon, it will react with the metal (titanium) 13 deposited on the silico...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com